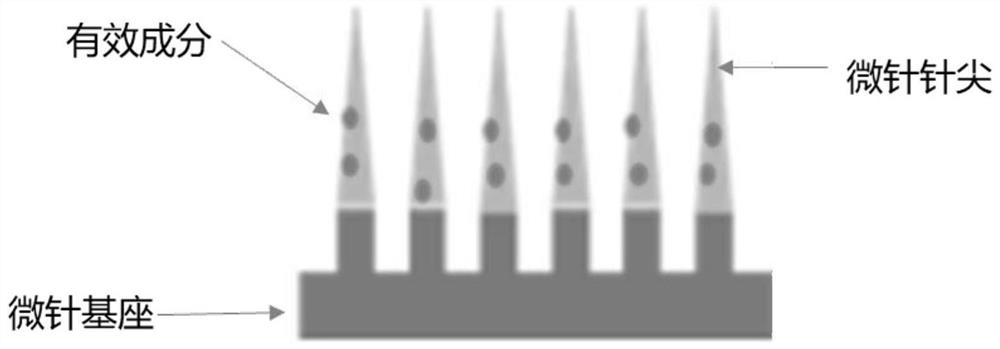

Responsive drug-release microneedle patch and preparation method thereof

A responsive, microneedle patch technology, applied in microneedles, drug delivery, pharmaceutical formulations, etc., can solve the problems of microneedle patches that cannot be administered continuously, lack of drug transdermal efficiency, etc., to improve drug loading capacity, Easy to insert into the human body and improve the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A microneedle patch for responsive release of drug-loaded methotrexate, comprising the following steps:

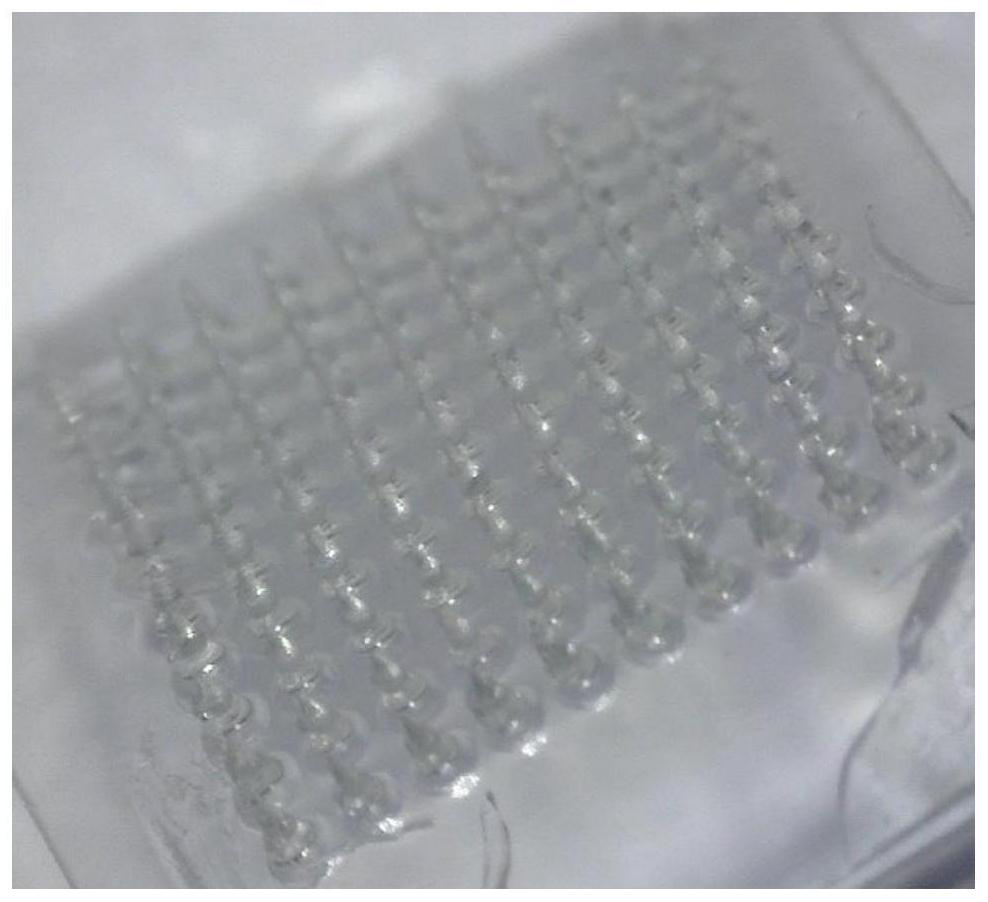

[0035] (1) Polydimethylsiloxane (PDMS) and Sylgard 184The PDMS curing agent is mixed and stirred evenly in a mass ratio of 10:1, and then poured on the microneedle template, the length of the needle tip is 600 μm, the length of the base is 600 μm, and the distance between two adjacent needle tips is 500 μm, and then - Vacuum at 0.09Mpa for 30 minutes to remove air bubbles, dry in an oven at 80°C for 5 hours to solidify and form, and separate the microneedle template after cooling at room temperature to obtain a microneedle array mold;

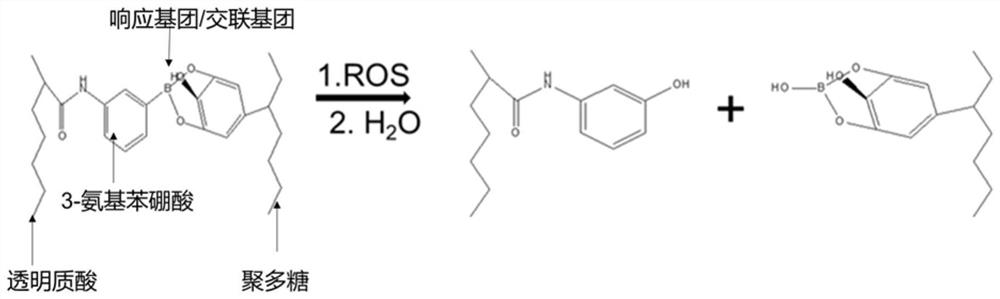

[0036] (2) First prepare the functional polymer, dissolve 100mg of hyaluronic acid in the mixed solution of water and DMF, the volume ratio of water and DMF is 3:2, then add 22mg of 3-aminophenylboronic acid, 70mg of 4-(4,6 -Dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride, under stirring conditions, adjust the pH to 6.5, rea...

Embodiment 2

[0039] A microneedle patch for responsive release of drug-loaded methotrexate, comprising the following steps:

[0040] (1) Polydimethylsiloxane (PDMS) and Sylgard 184 Mix and stir the PDMS curing agent in a mass ratio of 8:1, then pour it on the microneedle template, the length of the needle tip is 600 μm, the length of the base is 600 μm, and the distance between two adjacent needle tips is 500 μm, and then - Vacuum at 0.09Mpa for 30 minutes to remove air bubbles, dry in an oven at 80°C for 5 hours to solidify and form, and separate the microneedle template after cooling at room temperature to obtain a microneedle array mold;

[0041] (2) First prepare the functional polymer, dissolve 100mg chitosan oligosaccharide in 10ml water, then add 22mg 3-aminophenylboronic acid, 70mg 4-(4,6-dimethoxytriazin-2-yl)- 4-Methylmorpholine hydrochloride, under stirring conditions, adjust the pH to 6.5, react for 24 hours, dialyze with deionized water for 3 days after the reaction, and use...

Embodiment 3

[0044] A microneedle patch for responsive release of drug-loaded methotrexate, comprising the following steps:

[0045] (1) Polydimethylsiloxane (PDMS) and Sylgard 184 The PDMS curing agent is mixed and stirred evenly in a mass ratio of 10:1, and then poured on the microneedle template, the length of the needle tip is 600 μm, the length of the base is 600 μm, and the distance between two adjacent needle tips is 500 μm, and then - Vacuum at 0.09Mpa for 30 minutes to remove air bubbles, dry in an oven at 80°C for 5 hours to solidify and form, and separate the microneedle template after cooling at room temperature to obtain a microneedle array mold;

[0046] (2) First prepare the functional polymer, dissolve 100mg of hyaluronic acid in 10ml of water, then add 35mg of 3-aminomethylphenylboronic acid, 70mg of 4-(4,6-dimethoxytriazin-2-yl) -4-Methylmorpholine hydrochloride, under stirring conditions, adjust the pH to 6.5, react for 24 hours, dialyze with deionized water for 3 days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com