Preparation method of lithium monofluorophosphate

A monofluorolithium phosphate, monofluorophosphoric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc. Good and other problems, to achieve the effect of less by-products, simple process method and easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Technical solution of the present invention: a preparation method of lithium monofluorophosphate, comprising the following steps:

[0023] S1. Preparation of monofluorophosphoric acid: react phosphorus pentoxide and hydrofluoric acid in a closed reaction vessel made of fluorine-resistant material to obtain monofluorophosphoric acid;

[0024] Among them, the preparation of hydrofluoric acid: first prepare hydrofluoric acid with a mass fraction of 65% to 75% for later use, according to the concentration ratio, first take pure water in a polytetrafluoroplastic bucket, then slowly add the corresponding amount of hydrofluoric acid, stir and mix well Can;

[0025] Wherein, with phosphorus pentoxide and hydrofluoric acid as raw materials, the reaction molar ratio is n(P 2 o 5 ):n(HF)=1:2~1:2.05, first put a certain amount of phosphorus pentoxide into the airtight monel alloy reaction vessel, and then pump 69% of the corresponding amount of hydrofluoric acid into the reaction...

Embodiment 1

[0038] First take 710g of phosphorus pentoxide in a closed monel alloy reaction vessel, take 310g of prepared hydrofluoric acid, and pump it into the reaction vessel through a peristaltic pump at a constant speed. React for 2 hours, the reaction is over, raise the temperature to 110°C~120°C, adjust the vacuum to 0-0.05MPa, and the distillation time is 30min, connect the tail gas absorber of the reaction vessel to the end of the reaction vessel, and weigh the obtained monofluorophosphoric acid after the reaction is over 968g;

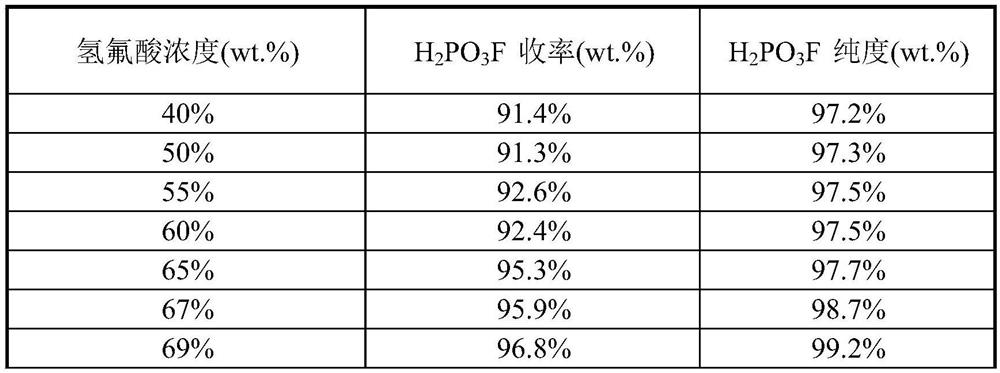

[0039]In example 1, different concentrations of hydrofluoric acid were used for experiments, and compared by calculating the yield and purity of monofluorophosphoric acid, the experimental data are as follows:

[0040]

[0041] .

Embodiment 2

[0043] Choose LiOH as the lithium source, put 432g of lithium hydroxide into the reaction vessel, take 900g of monofluorophosphoric acid in step S1 and pass it into the reaction vessel, heat while stirring, keep the reaction temperature at 50°C-100°C, and the reaction time is 2h, until the reaction is completely completed , raise the temperature to 100°C-150°C until the water is evaporated to dryness, and dry the crystallized product in a vacuum drying oven at a set temperature of 180°C-220°C for 3 hours to obtain 930 g of lithium monofluorophosphate with a yield of 92.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com