Needle coke, its preparation method and its preparation device

A technology of needle coke and green coke, which is applied in coke ovens, special forms of dry distillation, petroleum industry, etc. It can solve the problems of unqualified particle size distribution of needle coke products, improve utilization, increase yield, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Hereinafter, the method for preparing needle coke of the present invention is described in detail, so that those skilled in the art can better understand the present invention, but these specific descriptions are not intended to limit the scope of the present invention.

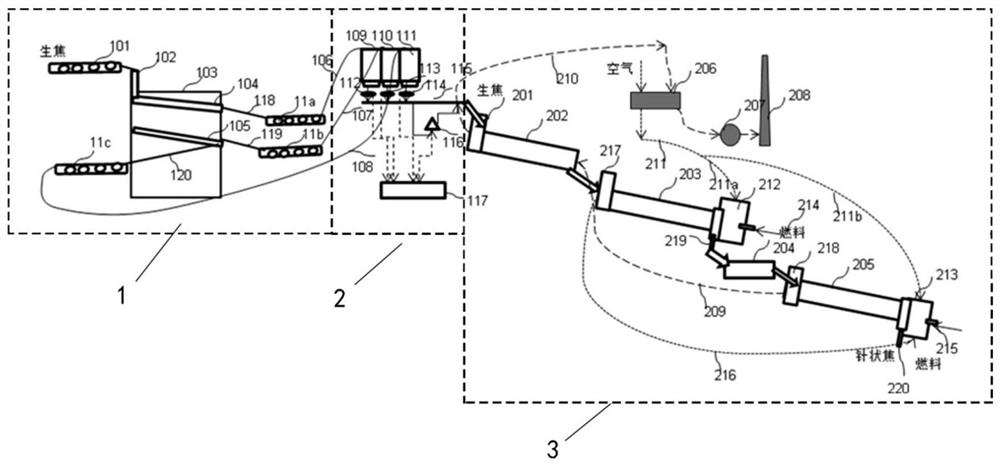

[0044] First, the green coke material that has been primary crushed and screened (the raw coke is conventional raw coke that has undergone delayed coking in this field) is transported to the subdividing equipment through the transmission belt 101, and first enters the vibrating screen shell through the discharge chute 102 After 103, through the first layer of vibrating screen 104, the sieve opening of 104 is designed to have a diameter of 8mm, and the particles on the top of the screen pass through the coarse particle discharge chute 118 and the transmission belt 11a and then pass through the coarse particle lifting device 106 and enter the coarse particle lower hopper 109 . The fine particles under th...

Embodiment 1

[0060] Firstly, raw coke materials that have been preliminarily crushed and screened are transported to the vibrating screen equipment through the transmission belt 101, first enter the vibrating screen shell 103 through the discharge chute 102, and then pass through the first layer of vibrating screen 104. The screen holes of 104 are designed to have a diameter of 8mm, the particles on the upper part of the sieve pass through the coarse particle discharge chute 118 and the transmission belt 11a and then pass through the coarse particle lifting device 106 and enter the coarse particle lower bin 109. The fine particles under the 104 screen pass through the second layer of vibrating screens 105, 105 The sieve aperture is 1mm, and the fine particle coke on the top of the 105 sieve passes through the fine particle discharge chute 119, the transmission belt 11b, and then enters the fine particle lower hopper 110 through the fine particle lifting device 107, and the powder at the bott...

Embodiment 2

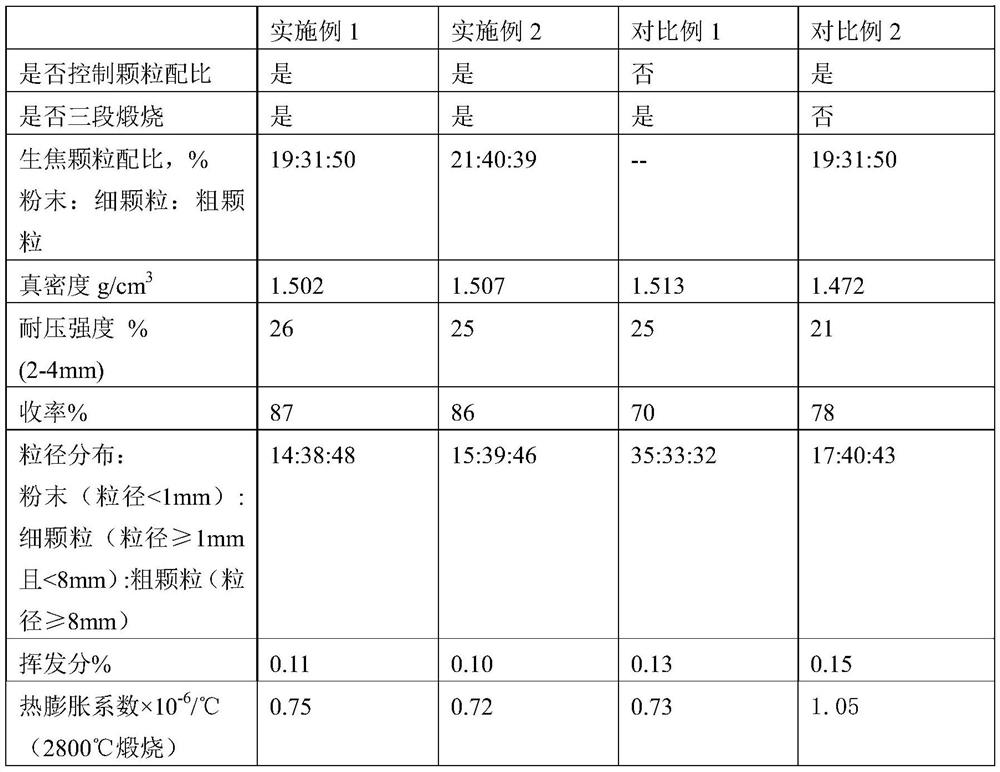

[0065] Through online particle detector 116 analysis and adjustment control coarse particle feeder 112, fine particle quantitative feeder 113, powder quantitative feeder 114, make the powder 21wt% at conveying belt 115 places, fine particle 40wt%, coarse particle 39wt% , the physical data of raw coke is water content of 6% (weight), volatile matter of 5%, true density of 1.623g / cm 3 (the same raw coke as embodiment 1). Calcination adopts three-stage calcination, and its operating parameters are shown in Table 1 below.

[0066] The true density of needle coke after cooling is 1.507g / cm 3 , the compressive strength of the particles is 26% (2-4mm), the particle distribution is 15wt% below 1mm, 39wt% 1-8mm, 46wt% above 8mm, needle coke yield (needle coke output / green coke input The amount of material) is 86%, the volatile matter is 0.10%, and the coefficient of thermal expansion (room temperature-600°C) is 0.72×10 -6 / °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com