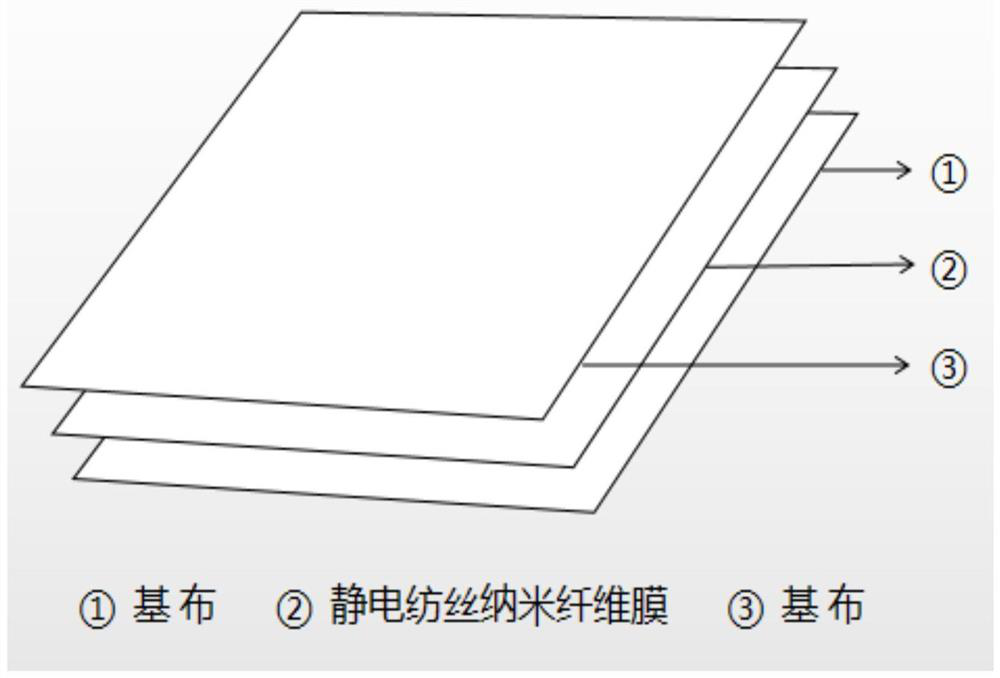

Method for manufacturing medical nanometer fiber protective clothing fabric based on electrospinning technology

An electrospinning technology and nanofiber technology are applied in the field of preparing nanofiber medical protective clothing fabrics based on electrospinning technology, which can solve the problems of medical staff discomfort, poor air permeability, poor heat and humidity comfort of garments, etc. The effect of high porosity and thermal and humidity comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

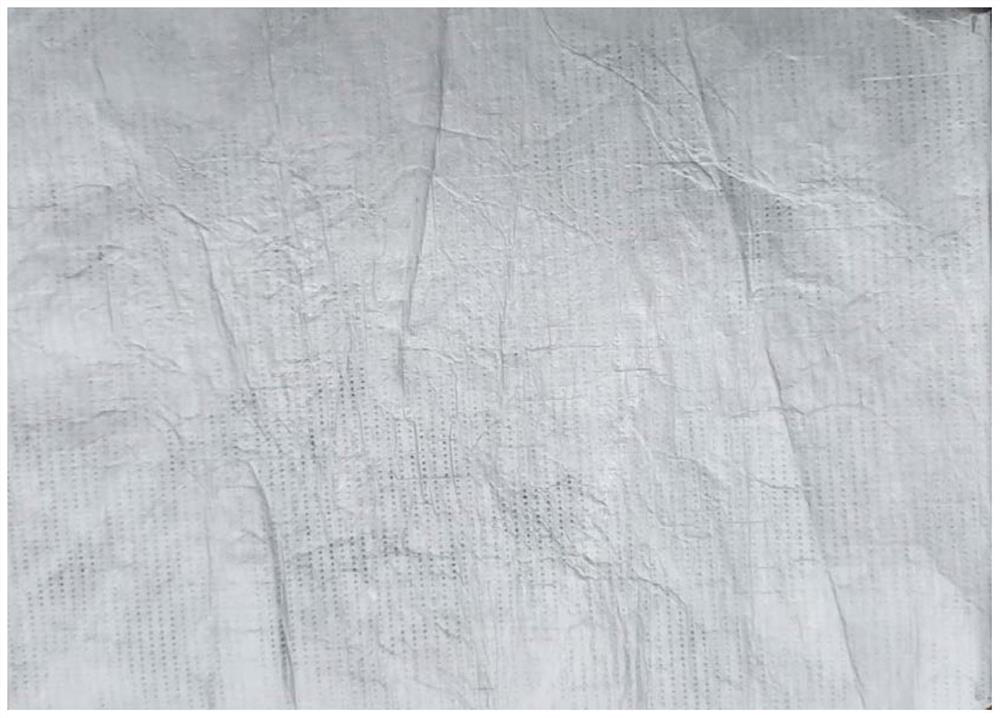

Image

Examples

Embodiment 1

[0034] The method for preparing nanofiber medical protective clothing fabric based on electrospinning technology in this embodiment, the steps are as follows:

[0035] (1) Dissolve polyurethane hot-melt adhesive powder in N,N-dimethylformamide, stir at room temperature for 3-4 hours, and prepare a hot-melt adhesive spinning solution with a mass fraction of 18%;

[0036] (2) Pass the hot-melt adhesive spinning solution in step (1) through the electrospinning equipment, receive it with polypropylene spunbond cloth, and perform electrospraying to obtain a hot-melt adhesive omentum; the square meter weight of the polypropylene spunbonded cloth is 50g / m 2 , the areal density of the hot melt adhesive film is 60g / m 2;The parameters of electrospinning are 33-37KV voltage, 17-19cm distance from the nozzle to the receiving base fabric, 78-82mm / min spinning speed, and 28-32mm / min walking speed of the receiving base fabric;

[0037] (3) Dissolve fluorine-containing polyurethane in a bea...

Embodiment 2

[0042] The method for preparing nanofiber medical protective clothing fabric based on electrospinning technology in this embodiment, the steps are as follows:

[0043] (1) Dissolve polyurethane hot-melt adhesive powder in N,N-dimethylformamide, stir at room temperature for 3-4 hours, and prepare a hot-melt adhesive spinning solution with a mass fraction of 18%;

[0044] (2) Pass the hot-melt adhesive spinning solution in step (1) through the electrospinning equipment, receive it with polypropylene spunbond cloth, and perform electrospraying to obtain a hot-melt adhesive omentum; the square meter weight of the polypropylene spunbonded cloth is 50g / m 2 , the areal density of the hot melt adhesive film is 60g / m 2 ;The parameters of electrospinning are voltage 35KV, distance from nozzle to receiving base fabric is 18cm, spinning speed 80mm / min, walking speed of receiving base fabric 30mm / min;

[0045] (3) Dissolve polylactic acid in a beaker of formic acid, heat at 60°C and stir...

Embodiment 3

[0051] The method for preparing nanofiber medical protective clothing fabric based on electrospinning technology in this embodiment, the steps are as follows:

[0052] (1) Dissolve polyurethane hot-melt adhesive powder in N,N-dimethylformamide, stir at room temperature for 3-4 hours, and prepare a hot-melt adhesive spinning solution with a mass fraction of 18%;

[0053] (2) Pass the hot-melt adhesive spinning solution in step (1) through the electrospinning equipment, receive it with spunlace cloth, and perform electrospraying to obtain a hot-melt adhesive omentum; the grammage of the spunlace cloth is 50g / m2 2 , the areal density of the hot melt adhesive film is 60g / m 2 ;The parameters of electrospinning are voltage 35KV, distance from nozzle to receiving base fabric is 18cm, spinning speed 80mm / min, walking speed of receiving base fabric 30mm / min;

[0054] (3) Dissolve polylactic acid in a beaker of formic acid, heat at 60°C and stir for 3-4 hours, and prepare a polylactic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com