Red-emitting quantum dots having narrow full width at half maximum and emission wavelength for application to high-color-purity display, and preparation method therefor

A technology of luminescent wavelength and quantum dots, which is applied in the field of preparation of red luminescent quantum dots, can solve the problems that the quantum efficiency cannot be achieved, and the half-value width of nanoparticles cannot be achieved, so as to improve the quantum efficiency, electron transmission characteristics, and electron mobility Excellent, easy-to-apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0137] The present invention can provide the above-mentioned quantum dots prepared by the above-mentioned preparation method of quantum dots.

[0138] Such quantum dots can achieve good luminous efficiency, color purity, and color reproducibility in a wide range of light-emitting regions from visible light to near-infrared regions, and can protect the surface and internal defects of the core due to external environments. Effect.

preparation example 1

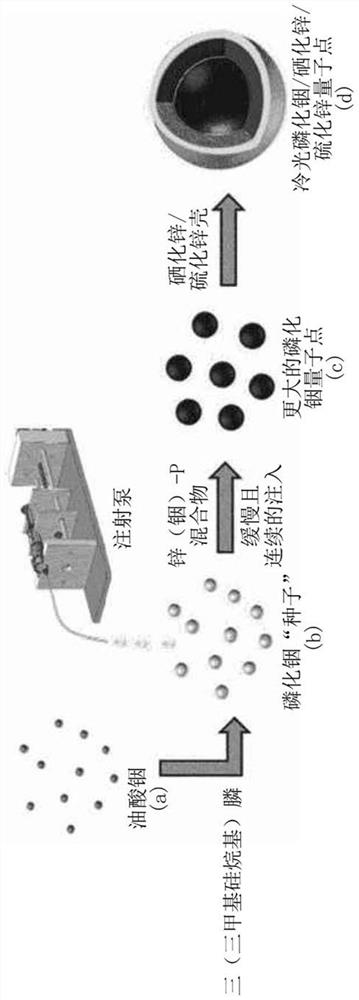

[0140] Zn(In)-P clusters

[0141] 1) After mixing 1mmol of indium acetate, 0.5mmol of zinc acetate, and 4mmol of oleic acid in 10ml of octadecene (ODE) in an Erlenmeyer flask to form a mixture, use the Schlenk line to pass through a reflux condenser After fixing, it was heated at a temperature of 120° C. for 12 hours in a vacuum.

[0142] 2) Fill the Erlenmeyer flask with nitrogen and cool to room temperature.

[0143] 3) will contain 0.66mmol tris (trimethylsilyl) phosphine ((TMS) 3 P) and a solution of 1 ml of tri-n-octylphosphine were quickly poured into the Erlenmeyer flask, and kept at room temperature for 60 minutes.

preparation example 2

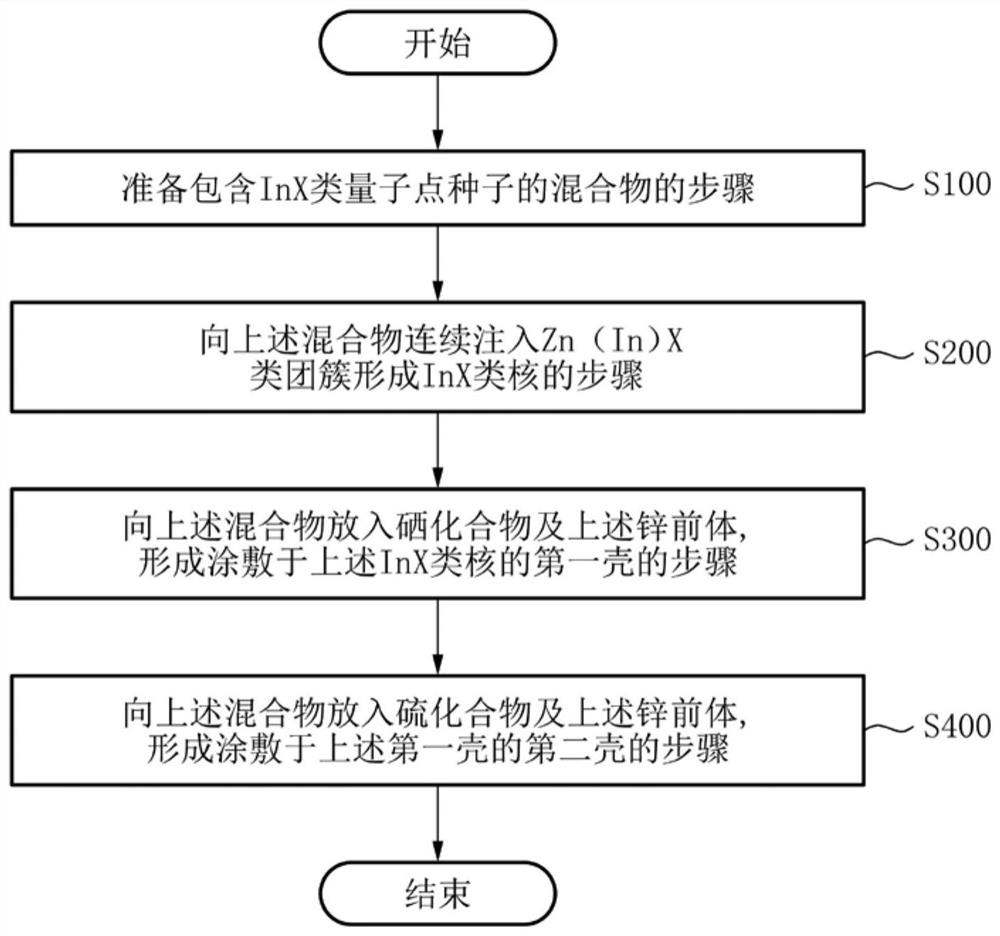

[0145]In(Zn)P / ZnSe / ZnS quantum dots

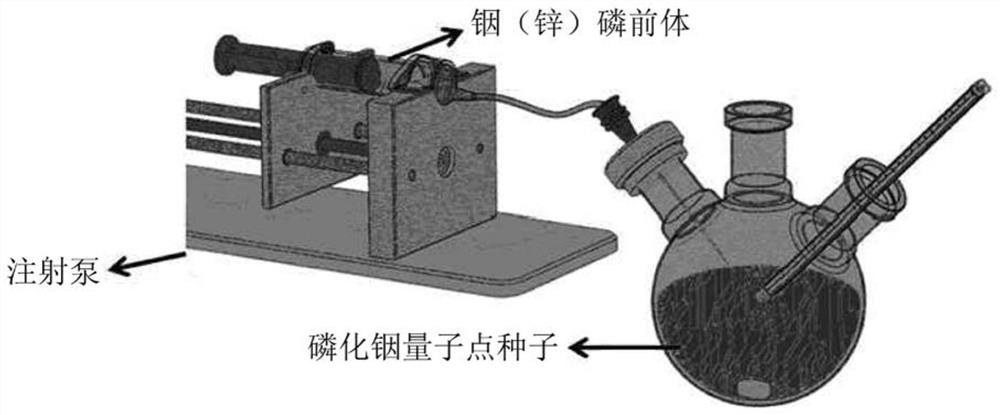

[0146] 1) Mix 5ml of InP quantum dot seeds with 10ml of dry octadecene, and heat to 280°C.

[0147] 2) Use a syringe pump to inject the In(Zn)P clusters prepared in Preparation 1 above at a rate of 1 ml / h to form In(Zn)P quantum dots.

[0148] 3) Cool the above In(Zn)P quantum dots to 150°C.

[0149] 4) Inject 1ml of 0.4M zinc stearate and keep at the same temperature for 30 minutes.

[0150] 5) Put 0.5ml of 0.4M tri-n-octylphosphine selenium (TOP-Se) into the Erlenmeyer flask and keep it at 300°C for 15 minutes.

[0151] 6) After injecting 1.5 ml of zinc stearate, keep it for 10 minutes, then inject 0.6 ml of tri-n-octylphosphine selenium, and keep it at 300° C. for 15 minutes.

[0152] 7) Wait for 10 minutes after injecting 1.5 ml of zinc stearate, then inject 0.6 ml of tri-n-octylphosphine selenium for 15 minutes to coat the ZnSe shell.

[0153] 8) After adding 2 ml of zinc stearate, inject 0.8 ml of tri-n-octylphosphine selenium to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com