Preparation of copper-aluminum bimetal oxide modified bamboo charcoal fiber composite material and application of composite material in removing ammonia nitrogen from water

A bimetallic oxide and bamboo charcoal fiber technology is applied in the direction of water pollutants, other chemical processes, water/sewage treatment, etc. It can solve a large number of bamboo leaf wastes and other problems, reduce preparation costs, facilitate recycling, and have good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of copper-aluminum double metal oxide modified bamboo charcoal fiber composite material, comprises the steps:

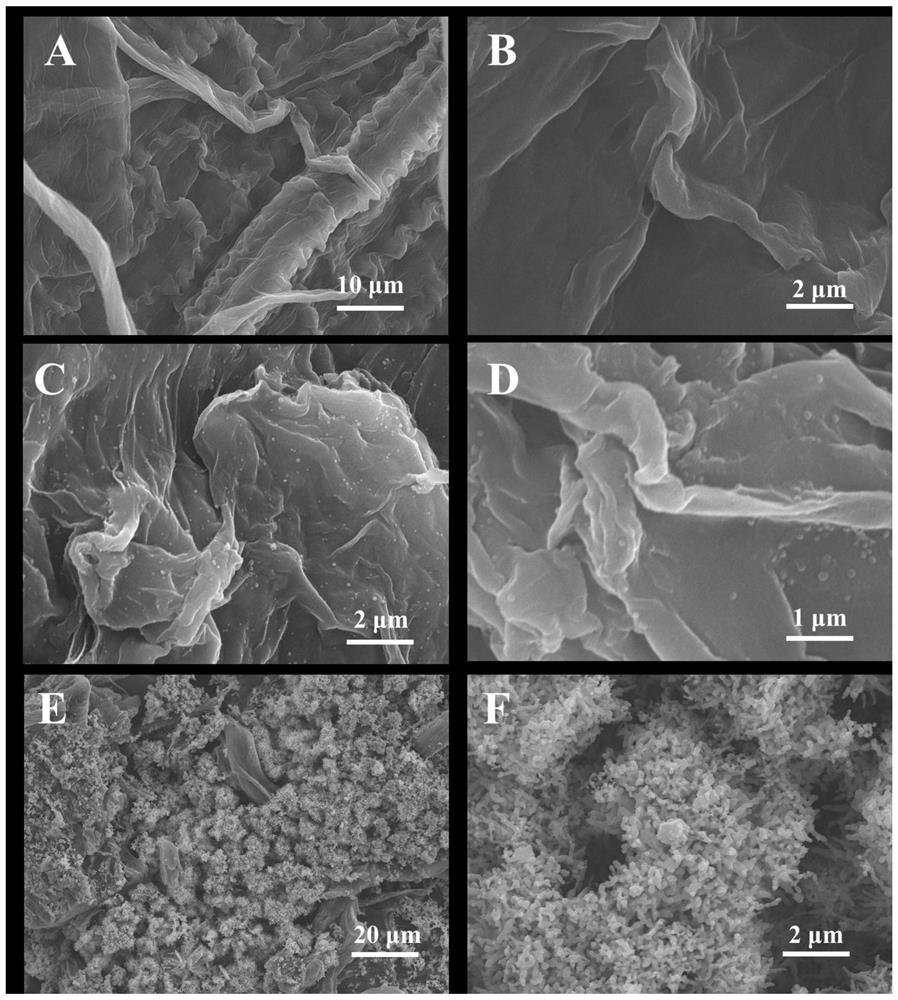

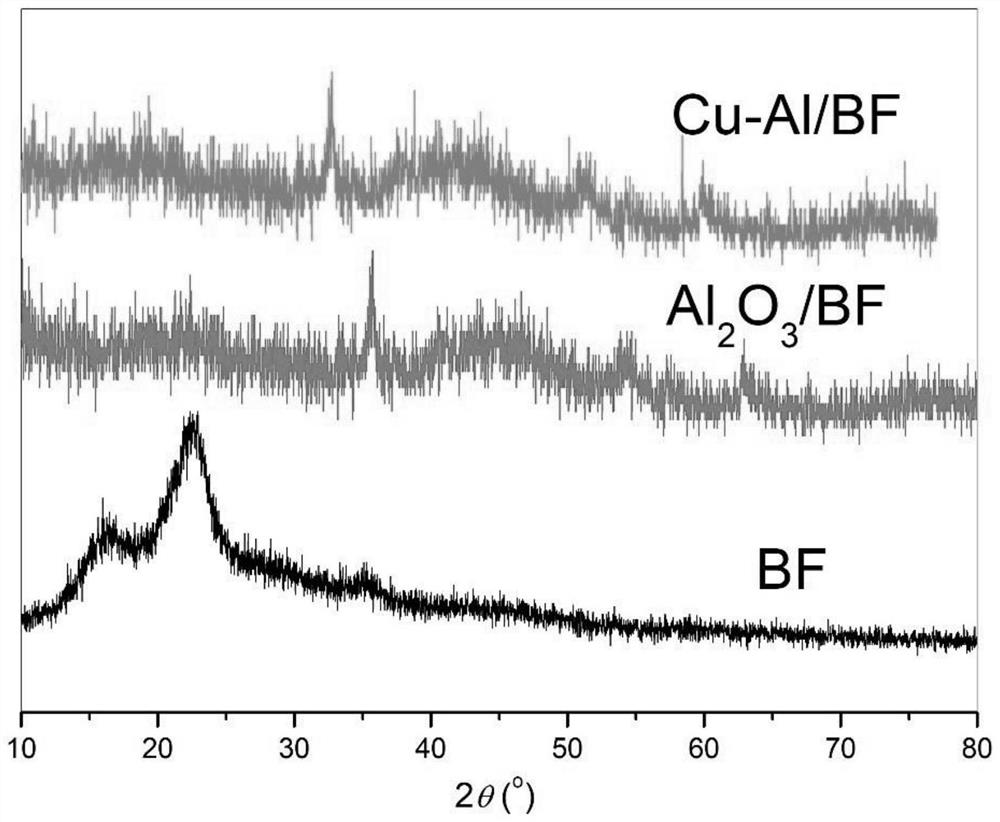

[0029] a) Soak the crushed bamboo leaves in sodium hydroxide solution at 20°C for 2 hours, remove impurities, wash the obtained yellow filamentous biomass fiber with deionized water for 3 times, add acetic acid acidified sodium hypochlorite solution and soak 2h, obtain white fiber (BF);

[0030] b) Prepare a 0.1mol / L aluminum nitrate solution, soak the obtained white fibers for 4 hours, filter them, dry the obtained samples and calcinate them at 250°C for 1 hour under nitrogen to obtain alumina-coated biochar fibers (Al 2 o 3 / BF);

[0031] c) According to the solid-to-liquid ratio of 0.1g:0.1g:0.05g:50mL, copper nitrate, Al 2 o 3 / BF, hexamethylenetetramine was dissolved in deionized water, and after fully stirring, the uniform suspension was transferred to a stainless steel reaction kettle, and after reacting at 60°C for 6 ho...

Embodiment 2

[0036] A kind of preparation method of copper-aluminum double metal oxide modified bamboo charcoal fiber composite material, comprises the steps:

[0037] a) Soak the crushed bamboo leaves in sodium hydroxide solution at 40°C for 4 hours, remove impurities, wash the obtained yellow filamentous biomass fiber with deionized water for 3 times, add acetic acid acidified sodium hypochlorite solution and soak 6h, obtain white fiber (BF);

[0038] b) Prepare a 0.4mol / L aluminum nitrate solution, soak the obtained white fiber for 6 hours, filter it, dry the obtained sample and calcinate it at 500°C for 4 hours under nitrogen to obtain alumina-coated biochar fiber (Al 2 o 3 / BF);

[0039] c) According to the solid-to-liquid ratio of 0.3g:0.6g:0.25g:75mL, copper nitrate, Al 2 o 3 / BF, hexamethylenetetramine dissolved in deionized water, after fully stirring, transfer the uniform suspension to a stainless steel reaction kettle, react at 120°C for 6 hours, filter, wash, and dry the prod...

Embodiment 3

[0044] A kind of preparation method of copper-aluminum double metal oxide modified bamboo charcoal fiber composite material, comprises the steps:

[0045] a) Soak the crushed bamboo leaves in sodium hydroxide solution at 80°C for 4 hours, remove impurities, wash the obtained yellow filamentous biomass fiber with deionized water for 3 times, add acetic acid acidified sodium hypochlorite solution and soak 5h, obtain white fiber (BF);

[0046] b) Prepare a 0.5mol / L aluminum nitrate solution, soak the obtained white fiber for 8 hours, filter it, dry the obtained sample, and calcinate it at 500°C for 2 hours under nitrogen to obtain alumina-coated biochar fibers (Al 2 o 3 / BF);

[0047] c) According to the solid-to-liquid ratio of 0.6g:0.3g:0.5g:75mL, copper nitrate, Al 2 o 3 / BF, hexamethylenetetramine dissolved in deionized water, after fully stirring, transfer the uniform suspension to a stainless steel reaction kettle, react at 90°C for 10h, filter, wash, and dry the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com