Preparation method and application of pomegranate-shaped magnetic visible light heterogeneous fenton catalyst material

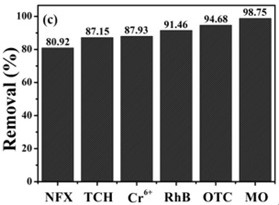

A technology of visible light and catalyst, applied in the field of water treatment, can solve the problems of low degradation efficiency of homogeneous Fenton system, low utilization rate of hydroxyl radicals, easy precipitation to form iron sludge, etc., to improve the utilization rate of visible light and stabilize green Economical, easily recyclable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

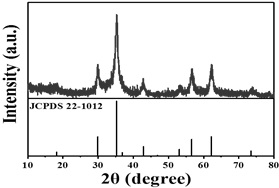

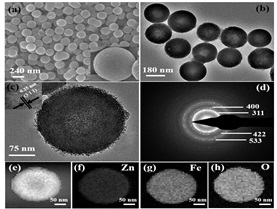

Embodiment 1

[0020] 200 mg of polyacrylic acid, add 1 mL of deionized water to sonic dissolve, stir and drop 100 ml of deionized water sonic, then drop 700 μL of ammonia for 30 min, weigh 223 mg of zinc nitrate added to the above solution, and then slowly add 400 ml of isopropanol to the solution. Weigh 300 mg of ferrous chloride tetrahydrate added to the above solution stirred for 12 h, the resulting mixed solution was centrifuged and separated (5000 rpm, 8min), the precipitate was washed several times with deionized water and ethanol, dried in a 65 °C oven for 15 h, taken out and placed in a muffle furnace, the air atmosphere was calcined at 500 °C for 12 h, and finally ZnFe2O4 photocatalytic material was obtained.

Embodiment 2

[0022] 100 mg of polyacrylic acid, add 1 mL of deionized water to ultrasonic dissolve, stir in 100 ml of deionized water sonication, then drop 500 μL of ammonia sonication for 30 min, weigh 200 mg of zinc nitrate added to the above solution, and then slowly add 300 ml of isopropanol to the solution. Weigh 200 mg of ferrous chloride tetrahydrate added to the above solution stirred for 10 h, the resulting mixed solution was centrifuged and separated (4000 rpm, 8min), the precipitate was washed several times with deionized water and ethanol, dried in a 65 °C oven for 12 h, taken out and placed in a muffle furnace, the air atmosphere was calcined at 500 °C for 18 h, and finally ZnFe2O4 photocatalytic material was obtained.

Embodiment 3

[0024]150 mg of polyacrylic acid, add 1 mL of deionized water to ultrasonic dissolution, stir to drop 100 ml of deionized water sonication, then drop 1000 μL of ammonia sonication for 30 min, weigh 250 mg of zinc nitrate added to the above solution, and then slowly add 400 ml of isopropanol to the solution. Weigh 250 mg of ferrous chloride chlorinated hydrate added to the above solution stirred for 12 h, the resulting mixed solution was centrifuged and separated (4500 rpm, 8min), the precipitation was washed several times with deionized water and ethanol, dried in a 65 °C oven for 16 h, removed and placed in a muffle furnace, the air atmosphere was calcined at 550 °C for 15 h, and finally ZnFe2O4 photocatalytic material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com