Monodispersed nanometer graphene lubricant additive and production method

A lubricating oil additive and nano-graphene technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of affecting lubricating oil lubrication and anti-wear effect, poor dispersibility of graphene, poor dispersibility, etc., and achieve optimal economical efficiency. Advantages and application prospects, the effect of improving dispersion and preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

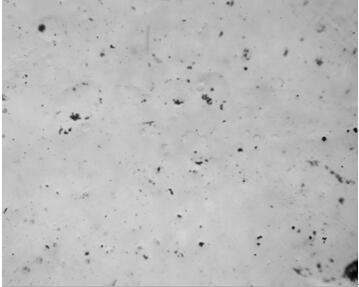

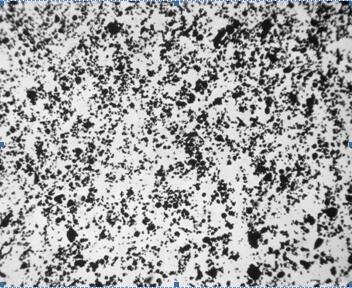

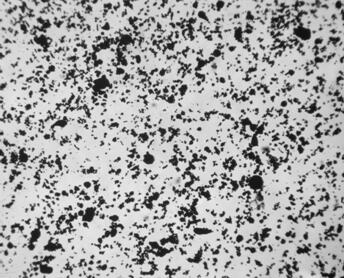

Image

Examples

Embodiment 1

[0035] (1) Add the graphene microchips into the cupric chloride solution first, then add the dispersant, and disperse through ultrasonic to disperse the graphene and fully absorb the cupric chloride, then filter out the excess cupric chloride solution, and finally dry it. Obtain the graphene that absorbs cupric chloride; Graphene microchip is the graphene microchip within 100 layers; Copper chloride solution is saturated cupric chloride solution; Dispersant is calcium sulfonate, and calcium sulfonate add-on is 2.5% of the mass of graphene microsheets; the frequency of ultrasonic dispersion is 40kHz, and the time is 7min;

[0036] (2) Put the copper chloride-adsorbed graphene prepared in step (1) into a box-type atmosphere resistance furnace, and then burn it quickly in a hydrogen atmosphere to reduce the copper chloride to copper, and then collect it to obtain copper Graphene-coated powder; the burning temperature is 460°C and the time is 2 minutes;

[0037] (3) First add the...

Embodiment 2

[0041] (1) Add the graphene microchips into the cupric chloride solution first, then add the dispersant, and disperse through ultrasonic to disperse the graphene and fully absorb the cupric chloride, then filter out the excess cupric chloride solution, and finally dry it. Obtain the graphene that absorbs cupric chloride; Graphene microchip is the graphene microchip within 100 layers; Copper chloride solution is saturated cupric chloride solution; Dispersant is calcium sulfonate, and calcium sulfonate add-on is 2% of the mass of graphene microsheets; the frequency of ultrasonic dispersion is 35kHz, and the time is 9min;

[0042] (2) Put the copper chloride-adsorbed graphene prepared in step (1) into a box-type atmosphere resistance furnace, and then burn it quickly in a hydrogen atmosphere to reduce the copper chloride to copper, and then collect it to obtain copper Graphene-coated powder; the burning temperature is 420°C and the time is 2.5 minutes;

[0043] (3) First add the...

Embodiment 3

[0047] (1) Add the graphene microchips into the cupric chloride solution first, then add the dispersant, and disperse through ultrasonic to disperse the graphene and fully absorb the cupric chloride, then filter out the excess cupric chloride solution, and finally dry it. Obtain the graphene that absorbs cupric chloride; Graphene microchip is the graphene microchip within 100 layers; Copper chloride solution is saturated cupric chloride solution; Dispersant is calcium sulfonate, and calcium sulfonate add-on is 4% of the mass of graphene microsheets; the frequency of ultrasonic dispersion is 45kHz, and the time is 6min;

[0048] (2) Put the copper chloride-adsorbed graphene prepared in step (1) into a box-type atmosphere resistance furnace, and then burn it quickly in a hydrogen atmosphere to reduce the copper chloride to copper, and then collect it to obtain copper Graphene-coated powder; the burning temperature is 480°C and the time is 1.5min;

[0049] (3) First add the copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com