Polyethylene fiber yarn and production process thereof

A polyethylene fiber and production process technology, applied in the field of yarn manufacturing, can solve the problems of single function of spinning machine, low production efficiency, low wear resistance level, etc., and achieve the effects of simple structure, convenient operation and enhanced mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

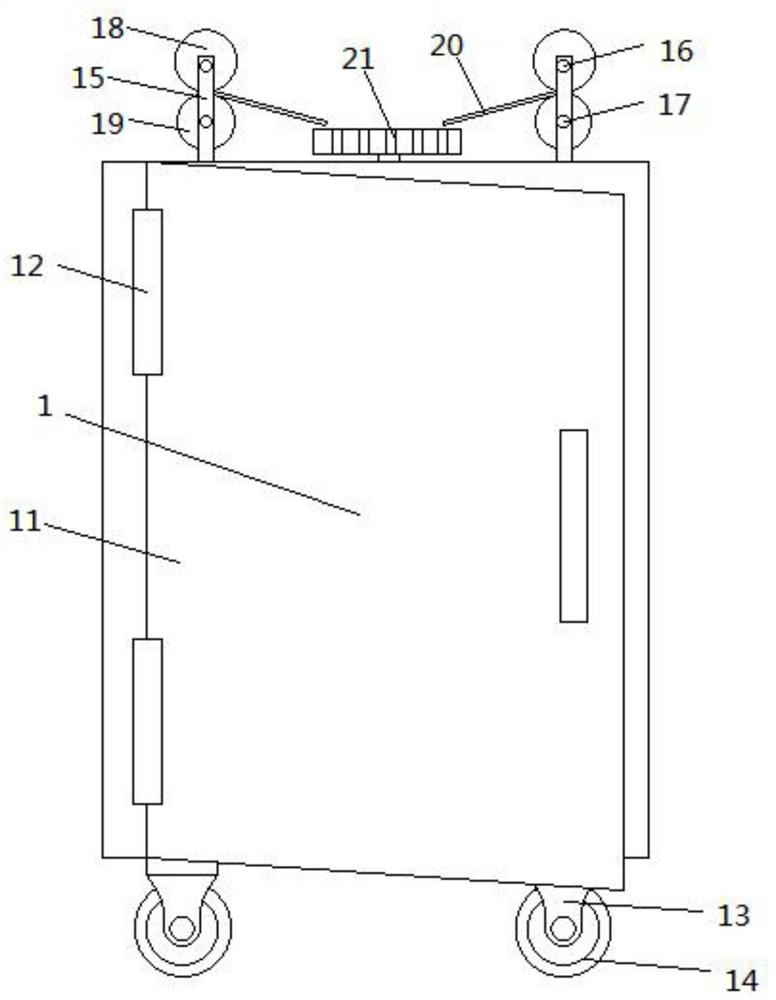

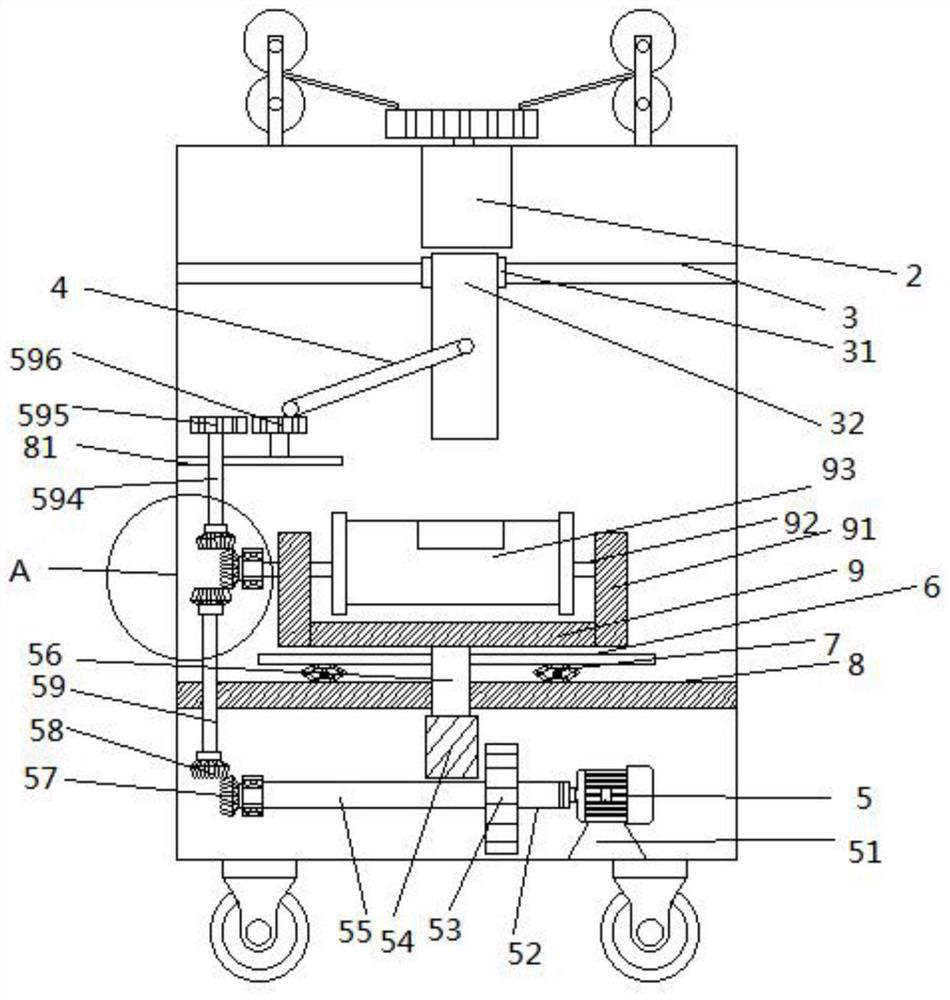

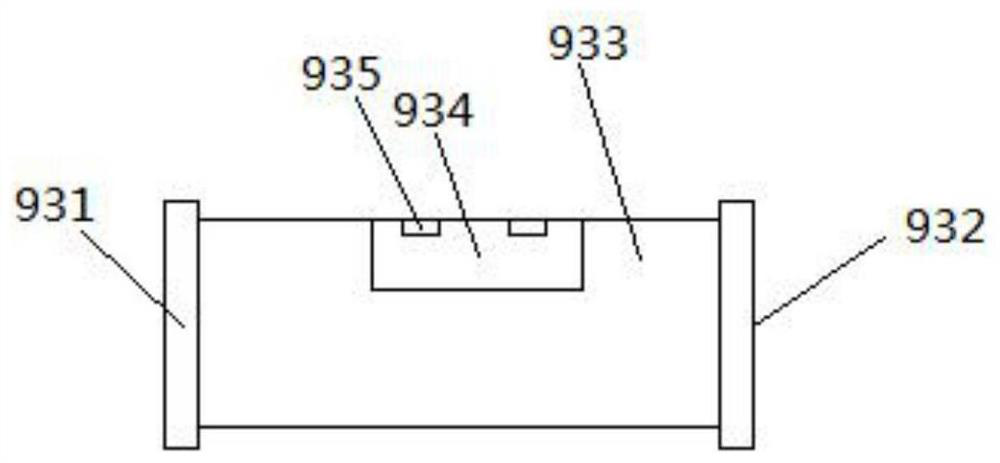

Image

Examples

Embodiment 1

[0045] A polyethylene fiber yarn, comprising the following raw materials by weight: 60 parts of polyethylene fiber, 30 parts of sisal fiber, 20 parts of viscose fiber, 10 parts of basalt fiber;

[0046] The linear density of the polyethylene fiber is 1.4dtex; the linear density of the sisal fiber is 1.0dtex; the linear density of the viscose fiber is 1.3dtex; the basalt fiber is 1.0dtex;

[0047] The preparation method of described polyethylene fiber comprises the steps:

[0048] The first step, weigh the following raw materials by weight, 50 parts of polyethylene raw materials, 2 parts of mercaptotrimethylsilane coupling agent, 1 part of sodium methyl silicate, 3 parts of n-butyl acrylate, 0.1 Antioxidant CA, 1 part of modifying agent and 200 parts of white oil; Described polyethylene raw material is that molecular weight is 600,000, is obtained by the polyethylene raw material of single active catalyst polymerization;

[0049] The second step is to add mercaptotrimethylsila...

Embodiment 2

[0071] A polyethylene fiber yarn, comprising the following raw materials by weight: 80 parts of polyethylene fiber, 40 parts of sisal fiber, 25 parts of viscose fiber, 13 parts of basalt fiber;

[0072] The linear density of the polyethylene fiber is 1.6dtex; the linear density of the sisal fiber is 1.3dtex; the linear density of the viscose fiber is 1.5dtex; the basalt fiber is 1.4dtex;

[0073] The preparation method of described polyethylene fiber comprises the steps:

[0074] The first step, weigh the following raw materials by weight, 60 parts of polyethylene raw materials, 4 parts of mercaptotrimethylsilane coupling agent, 1.2 parts of sodium methyl silicate, 4 parts of n-butyl acrylate, 0.4 parts The antioxidant CA of part, 4 parts of modifying agents and 250 parts of white oil; Described polyethylene raw material is that molecular weight is 1,000,000, is obtained by the polyethylene raw material of single active catalyst polymerization;

[0075] The second step is to ...

Embodiment 3

[0085] A polyethylene fiber yarn, comprising the following raw materials by weight: 120 parts of polyethylene fiber, 50 parts of sisal fiber, 30 parts of viscose fiber, 15 parts of basalt fiber;

[0086] The linear density of the polyethylene fiber is 2.0dtex; the linear density of the sisal fiber is 1.5dtex; the linear density of the viscose fiber is 1.8dtex; the basalt fiber is 1.5dtex;

[0087] The preparation method of described polyethylene fiber comprises the steps:

[0088] The first step, weigh the following raw materials in parts by weight, 80 parts of polyethylene raw materials, 5 parts of mercaptotrimethylsilane coupling agent, 1.5 parts of sodium methyl silicate, 5 parts of n-butyl acrylate, 0.5 parts The antioxidant CA of part, 5 parts of modifying agents and 300 parts of white oil; Described polyethylene raw material is that molecular weight is 1,200,000, is obtained by the polyethylene raw material of single active catalyst polymerization;

[0089] The second s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com