Os element secondary oxidative distillation separation device and separation method and application thereof

A technology of secondary oxidation and distillation separation, which is applied to measurement devices, analytical materials, preparation of samples for testing, etc., can solve the problems of poor signal intensity of Os element measurement, low enrichment of Os element, and high acidity of absorption liquid, etc. Achieve the effect of improving the measurement signal strength and measurement accuracy, reducing the risk of explosion, and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Accurately weigh 0.8g pyrite sample, 0.1g molybdenite standard substance JDC, 185 Re- 190 The Os mixed diluent was put into the Carius tube, and then the Carius tube containing the mineral sample was placed in the ethanol-liquid nitrogen mixed freezing solution at -80°C to -50°C, and then 9 mL of reverse aqua regia was added to the Carius tube. After the material in the Carius tube is completely frozen, use an oxygen-gas torch to heat the Carius tube to melt and seal it. The sealed Carius tube was then heated in an oven at 220 °C for 48 h.

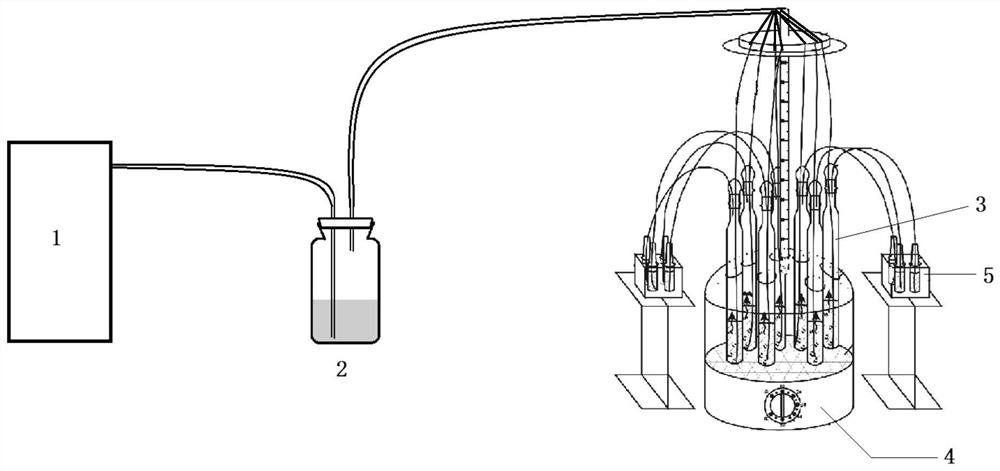

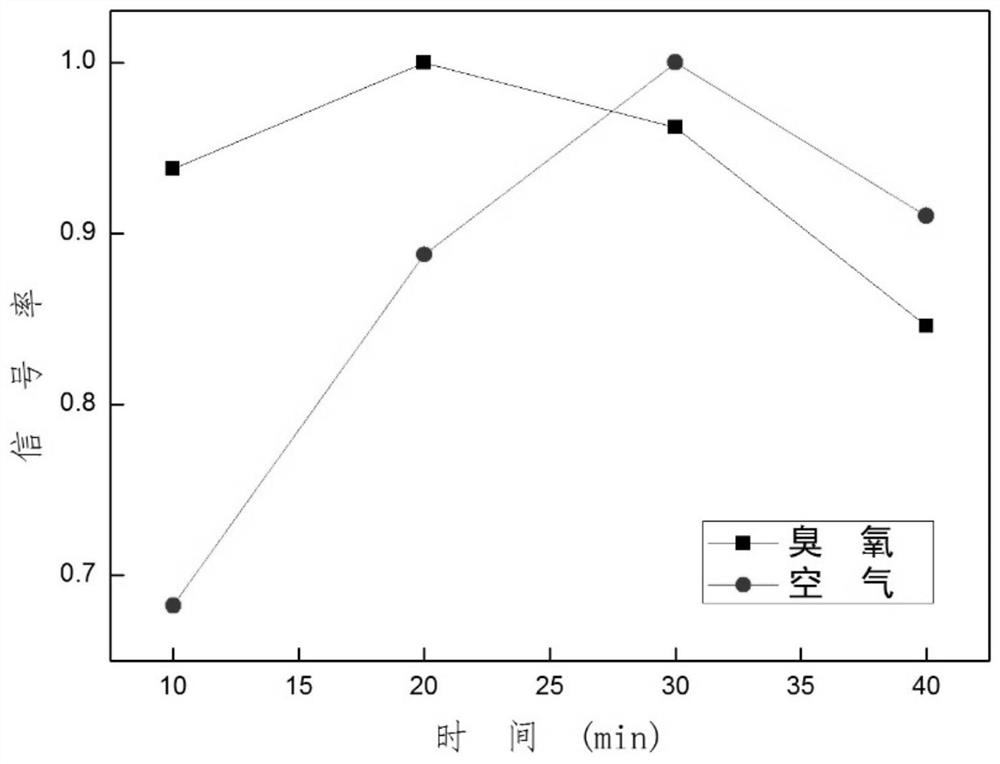

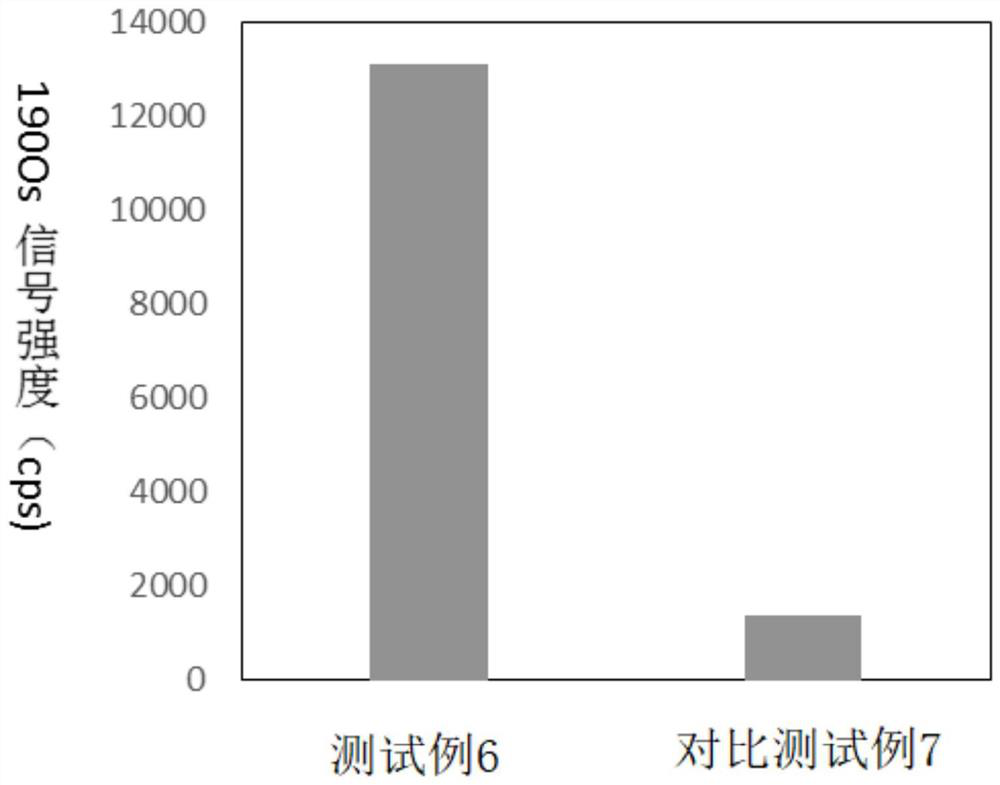

[0110] After heating, take out the Carius tube and cool it down to room temperature, then put it into the ethanol-liquid nitrogen mixed freezing solution at -80°C to -50°C to open the tube, and add 9 mL of high-purity water to dilute after opening the tube. Then install the Carius tube in the electric heating steam bath, pass in ozone, and after verifying the air tightness, adjust the gas flow to 40-50mL / min, start the electric he...

Embodiment 2

[0116] The operation is the same as that of Re-Os isotope dating test example 1, except that 0.01 g of molybdenite standard substance HLP (GBW04435) is used instead of 0.1 g of molybdenite standard substance JDC (GBW04436).

[0117] Embodiment 2 repeats three times, and the results are as shown in table 2:

[0118] Table 2

[0119]

[0120] Among them, the first 2S in Table 2 is taken as an example, which indicates the standard deviation of twice the Re content. As can be seen from Table 2, the ages in the molybdenite standard substance HLP (GBW04435) and JDC (GBW04436) measured in the present invention are respectively 219.8 ± 1.1Ma and 139.6 ± 0.9Ma, while the molybdenite standard substance HLP (GBW04435) and The content of JDC (GBW04436) is 221.4±5.6Ma and 139.6±3.8Ma, which shows that the determination method in the present invention has high precision.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com