A lignin-based polyelectrolyte nanofiltration membrane and preparation method thereof

A polyelectrolyte, lignin-based technology, applied in the field of polyelectrolyte nanofiltration membrane and its preparation, can solve the problem that it cannot be directly used as a raw material for membrane production, achieve broad scale application prospects, improve anti-pollution ability, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of polyelectrolyte and sodium lignosulfonate aqueous solution: according to the mass concentration of 1g / L, polyethyleneimine is dissolved in deionized water, and it is used as polyethyleneimine aqueous solution after dissolving evenly; according to the mass concentration of 1g / L Sodium lignosulfonate with a sulfonation degree of 30% is dissolved in deionized water, and after being uniformly dissolved, it is used as an aqueous solution of sodium lignosulfonate for later use;

[0040] (2) Preparation of cross-linking agent aqueous solution: according to the molar concentration of 0.1mol / L, glutaraldehyde was dissolved in deionized water, and after dissolving evenly, it was used as glutaraldehyde aqueous solution for subsequent use;

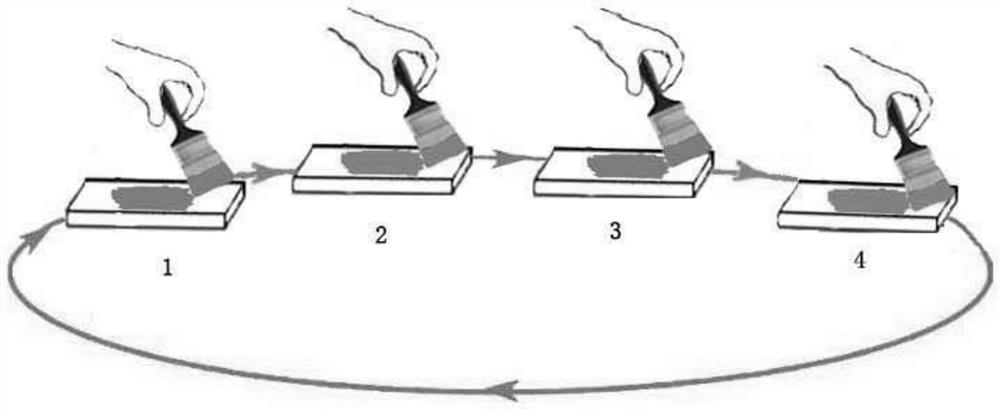

[0041](3) Raw materials for brushing: Brush the surface of the polysulfone ultrafiltration membrane with a soft brush in the following order: polyethyleneimine aqueous solution / glutaraldehyde aqueous solution / sodium lignosulfo...

Embodiment 2

[0044] A lignin-based polyelectrolyte nanofiltration membrane was prepared according to the method of Example 1, the only difference being that polyallylamine hydrochloride was used as the positively charged polyelectrolyte.

Embodiment 3

[0046] The lignin-based polyelectrolyte nanofiltration membrane was prepared according to the method of Example 1, the only difference being that polydiallyldimethylammonium chloride was used as the positively charged polyelectrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com