Mn <4+> activated aluminophosphate red fluorescent powder, preparation method thereof and application of preparation method in plant growth light emitting diode

A technology of red fluorescent powder and aluminum phosphate, applied in the direction of botanical equipment and methods, applications, luminescent materials, etc., can solve the problems of low luminous efficiency and poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

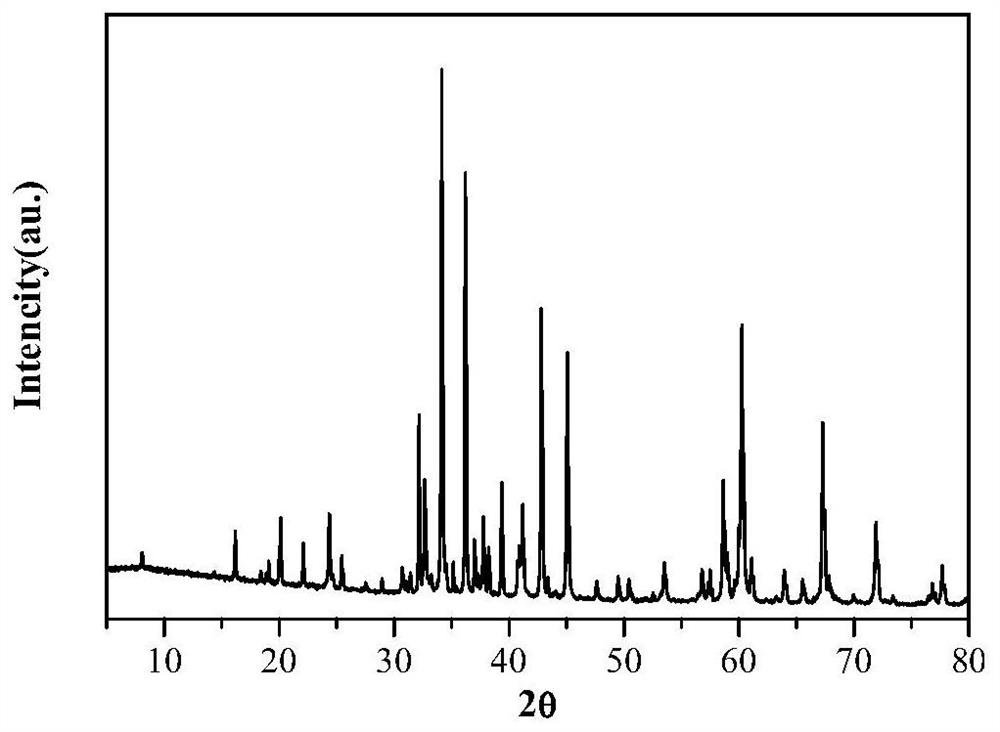

[0034] According to CaAl 12-0.75x (PO 4 ) m o 19-1.5m :xMn 4+ (0.001≤x≤0.15, 0.01≤m≤1.0) in the stoichiometric ratio of Mn, Al, Ca, P, weigh manganese carbonate 0.0012g, aluminum hydroxide 0.9354g, calcium carbonate 0.1000g and ammonium dihydrogen phosphate 0.0063g, the raw materials were mixed and placed in an agate mortar, 1ml of absolute ethanol was added and ground, and the obtained mixture was placed in a muffle furnace for calcination under an air atmosphere at a calcination temperature of 1450°C and a calcination time of 3h. After the calcination is finished, wait for it to cool naturally to room temperature, take out the sample and grind it finely, and seal it up for later use to obtain a kind of Mn 4+ Activated aluminophosphate red phosphor.

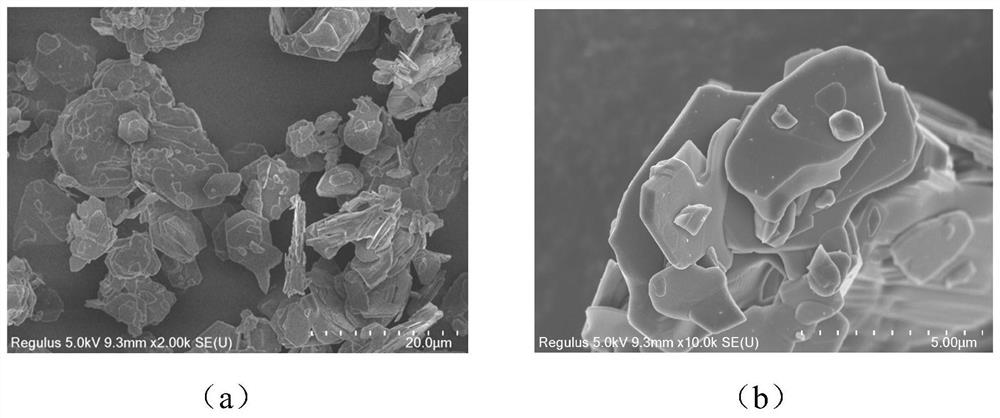

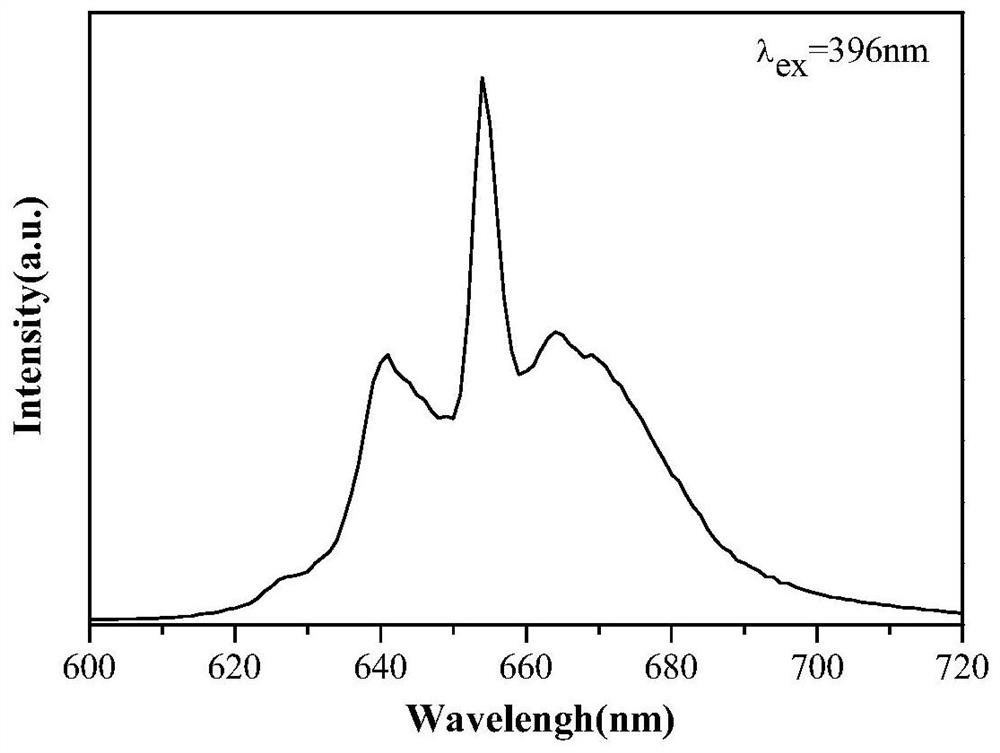

[0035] Taking the aluminophosphate red fluorescent powder of Example 1 as an example for experimental verification, the results are as follows:

[0036] The aluminophosphate red fluorescent powder prepared in embodiment 1 ...

Embodiment 2

[0042] According to CaAl 12-0.75x (PO 4 ) m o 19-1.5m :xMn 4+ For the stoichiometric ratio of Mn, Al, Ca, and P in (0.001≤x≤0.15, 0.01≤m≤1.0), respectively weigh 0.003g of manganese acetate, 1.227g of aluminum oxide, 0.120g of calcium carbonate, and 0.0071g of phosphoric acid. Mix the weighed medicines in an agate mortar, add 2ml of absolute ethanol and grind them. The obtained mixture is calcined in an air atmosphere in a muffle furnace. The calcining temperature is 1400° C. and the calcining time is 4 hours. After the calcination, it is naturally cooled to room temperature and ground evenly to obtain a Mn 4+ Activated aluminophosphate red phosphor.

Embodiment 3

[0044] According to CaAl 12-0.75x (PO 4 ) m o 19-1.5m :xMn 4+ The stoichiometric ratio of Mn, Al, Ca, P in (0.001≤x≤0.15, 0.01≤m≤1.0), weighed manganese dioxide MnO 2 0.0015g, aluminum nitrate 4.4920g, calcium oxide 0.056g, ammonium dihydrogen phosphate 0.0076g. Mix the weighed medicines in an agate mortar, add 3ml of absolute ethanol and then grind. The obtained mixture is calcined in an air atmosphere in a muffle furnace. The calcining temperature is 1300° C. and the calcining time is 6 hours. After the calcination, it is naturally cooled to room temperature and ground evenly to obtain a Mn 4+ Activated aluminophosphate red phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com