Anti-bacterial nanofiber material and application thereof

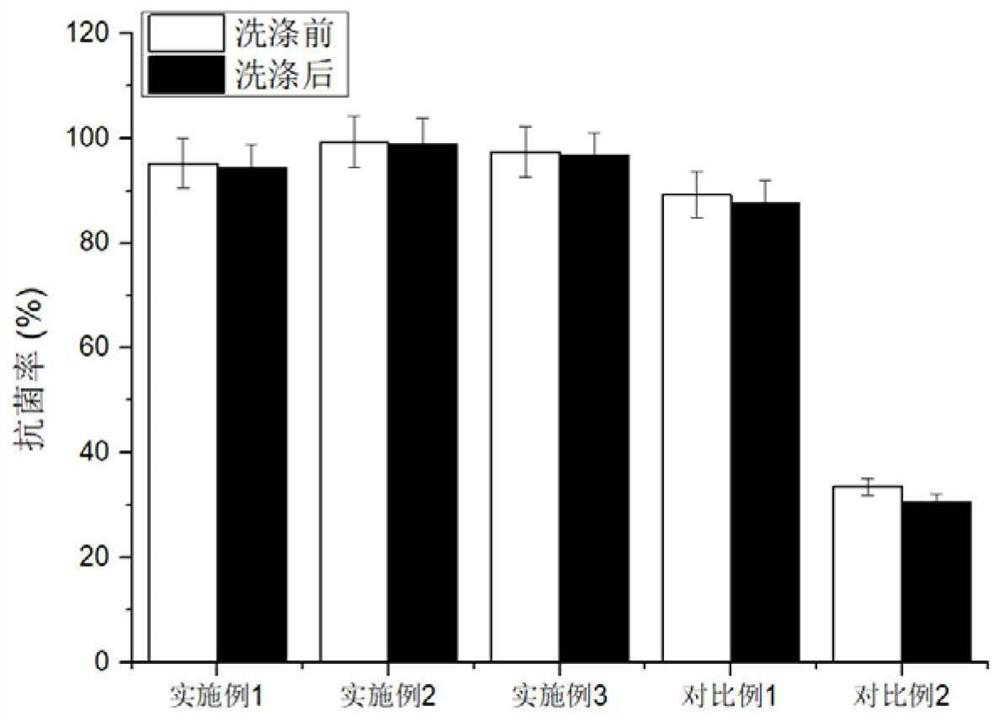

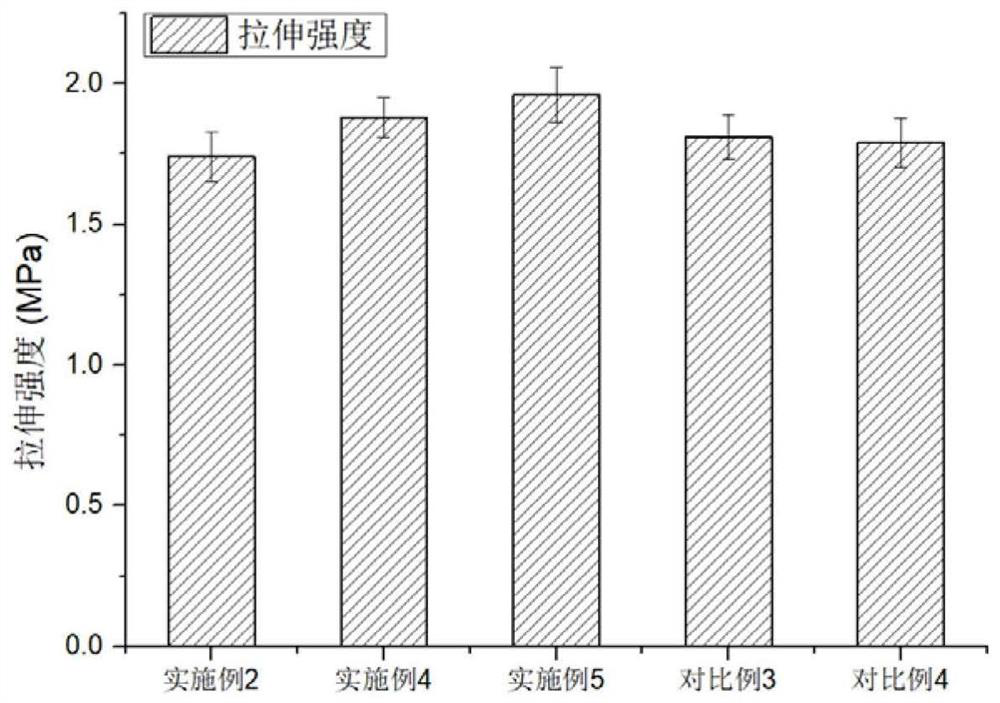

A nanofiber, antibacterial technology, applied in the field of antibacterial nanofiber materials, can solve the problems of reducing the mechanical properties of fibers, easy to block needles, easy to fall off, etc., to achieve good washing resistance, improved mechanical properties, and good antibacterial effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of antibacterial nanofiber,

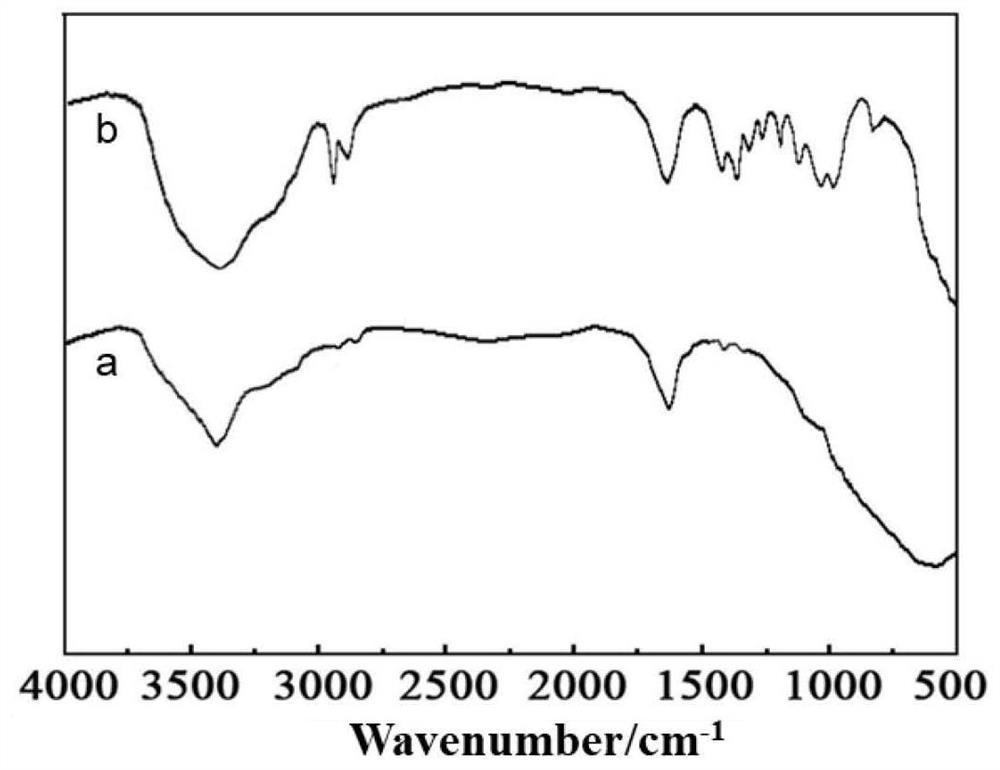

[0026] Modification of titanium dioxide nanoparticles: ultrasonically disperse titanium dioxide nanoparticles in absolute ethanol to obtain a titanium dioxide nanoparticle dispersion, add polydipside, stir and disperse for 1 hour to obtain a polydipside / titanium dioxide mixed solution; add water to the mixture under stirring, and filter with suction. , the filter cake was re-dispersed in water and stirred for 1 h, and the suction filtration and washing were repeated twice; after drying at 25 °C, the titanium dioxide pretreated powder was obtained after ball milling with a ball mill for 12 h; the titanium dioxide pretreated powder was placed in a crucible, and the Modified titanium dioxide was prepared after calcining in a Furnace for 4 hours; the mass fraction of the titanium dioxide nanoparticle dispersion was 4wt%, the addition amount of polydipside was 160wt% of the titanium dioxide nanoparticle, and the addit...

Embodiment 2

[0030] A kind of preparation method of antibacterial nanofiber,

[0031]Modification of titanium dioxide nanoparticles: ultrasonically disperse titanium dioxide nanoparticles in absolute ethanol to obtain a titanium dioxide nanoparticle dispersion, add polydipside, stir and disperse for 1 hour to obtain a polydipside / titanium dioxide mixed solution; add water to the mixture under stirring, and filter with suction. , the filter cake was redispersed in water and stirred for 1 h, and the suction filtration and washing were repeated twice; after drying at 25 °C, the titanium dioxide pretreated powder was obtained after ball milling with a ball mill for 12 h; the titanium dioxide pretreated powder was placed in a crucible, and the Modified titanium dioxide was prepared after calcining in a Furnace for 4 hours; the mass fraction of the titanium dioxide nanoparticle dispersion was 4wt%, the addition amount of polygoside was 300wt% of the titanium dioxide nanoparticle, and the addition...

Embodiment 3

[0035] A kind of preparation method of antibacterial nanofiber,

[0036] Modification of titanium dioxide nanoparticles: ultrasonically disperse titanium dioxide nanoparticles in absolute ethanol to obtain a titanium dioxide nanoparticle dispersion, add polydipside, stir and disperse for 1 hour to obtain a polydipside / titanium dioxide mixed solution; add water to the mixture under stirring, and filter with suction. , the filter cake was redispersed in water and stirred for 1 h, and the suction filtration and washing were repeated twice; after drying at 25 °C, the titanium dioxide pretreated powder was obtained after ball milling with a ball mill for 12 h; the titanium dioxide pretreated powder was placed in a crucible, and the Modified titanium dioxide was prepared after calcining in a Furnace for 4 hours; the mass fraction of the titanium dioxide nanoparticle dispersion was 4wt%, the addition amount of polygoside was 300wt% of the titanium dioxide nanoparticle, and the additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com