Environment-friendly polyester fabric low-temperature dyeing promoting protective agent and preparation method thereof

A low-temperature dyeing and protective agent technology, applied in dyeing methods, textiles and papermaking, etc., can solve the problems of low utilization rate of dyes, good low-temperature colorability, strict temperature requirements, etc., to increase coloring uniformity, improve Dye color yield, the effect of solving the cylinder difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method of the above-mentioned environment-friendly polyester fabric low-temperature dyeing accelerating and protecting agent, comprising the following steps:

[0046] (1) Add the formulated amount of fatty alcohol polyoxyethylene ether AEO-9 into water at a temperature of 58-62°C, stir and dissolve to obtain liquid 1;

[0047] (2) Add formula amount of isomeric alcohol polyoxyethylene ether EH-3, isomeric alcohol TO-5 and anionic surfactant to liquid 1 obtained in step (1), stir and dissolve to obtain liquid 2;

[0048] (3) Add maleic anhydride derivatives, organic esters, solvents and antibacterial agents in a formula amount to the liquid 2 obtained in step (2), stir and dissolve, and pass through a 0.45 μm filter membrane to obtain the low-temperature dyeing promotion protection agent.

Embodiment 1-6

[0049] Embodiment 1-6 A kind of environment-friendly polyester fabric low-temperature dyeing accelerating protective agent and preparation method thereof

[0050] Examples 1-6 The components and dosage (parts by weight) of an environment-friendly polyester fabric low-temperature dyeing accelerating and protecting agent are shown in Table 1.

[0051] Table 1

[0052] components Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Maleic anhydride derivatives 25 45 26 44 30 35 Organic esters 15 30 16 28 20 23 nonionic surfactant 15 35 21 30 24 30 EH-3 / AEO-9 / TO-5 2:5:2 2:5:2 2:5:2 2:5:2 2:5:2 2:5:2 anionic surfactant 10 15 11 13 12 15 antibacterial agent 1 3 1.2 2.8 2 2.6 solvent 5 10 6 9 8 7 water 35 45 36 44 42 38

[0053] The preparation method of above-mentioned embodiment 1-6: comprise the following steps:

[0054] (1) Add the formulated amount of fatty al...

experiment example 1

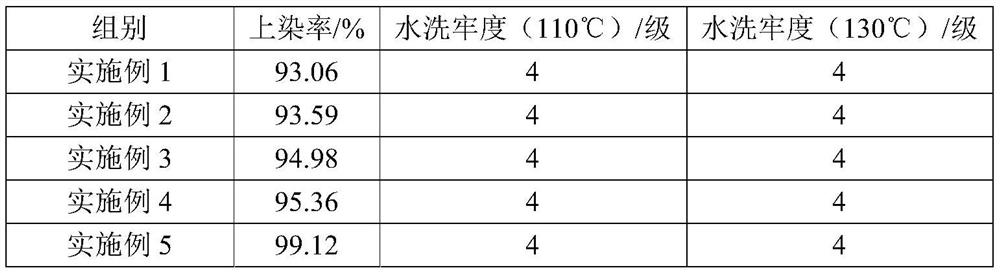

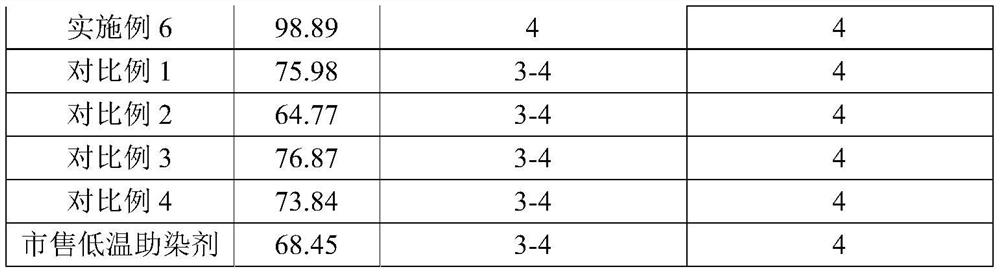

[0070] (1) Low temperature dyeing promotion performance test

[0071] Formula: PH buffer 45 1g / L+D-RG yellow brown 0.8%+D-RG ruby 0.4%+PLUS navy blue 0.5%+low temperature dyeing accelerator 1g / L;

[0072] Fabric: 300D white polyester Oxford 5g; liquor ratio: 1:20; steel balls: 10 pcs / cup;

[0073] Process: Dyeing at 110°C×60min→cloth output→washing→drying→test dye uptake (normal dyeing at 130°C is used as a standard sample for 100% dye uptake).

[0074] (2) Effect of low temperature dyeing on fabric fastness:

[0075] Formula: PH buffer 45 1g / L+disperse black ECT 4%+low temperature dyeing promotion and protection agent 0.5g / L;

[0076] Fabric: 300D white polyester Oxford 5g; liquor ratio: 1:20; steel balls: 10 pcs / cup;

[0077] Process: 110 / 130℃×60min dyeing→cloth output→washing→drying→test Y value.

[0078] The results are shown in Table 2.

[0079] Table 2

[0080]

[0081]

[0082] As can be seen from the above table, the low-temperature dyeing accelerator and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com