Production method of perovskite thin film and preparation method of perovskite solar cell

A production method and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult process, difficult mass production, and high production cost of perovskite films, so as to reduce environmental pollution and reduce costs. Membrane difficulty, good for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

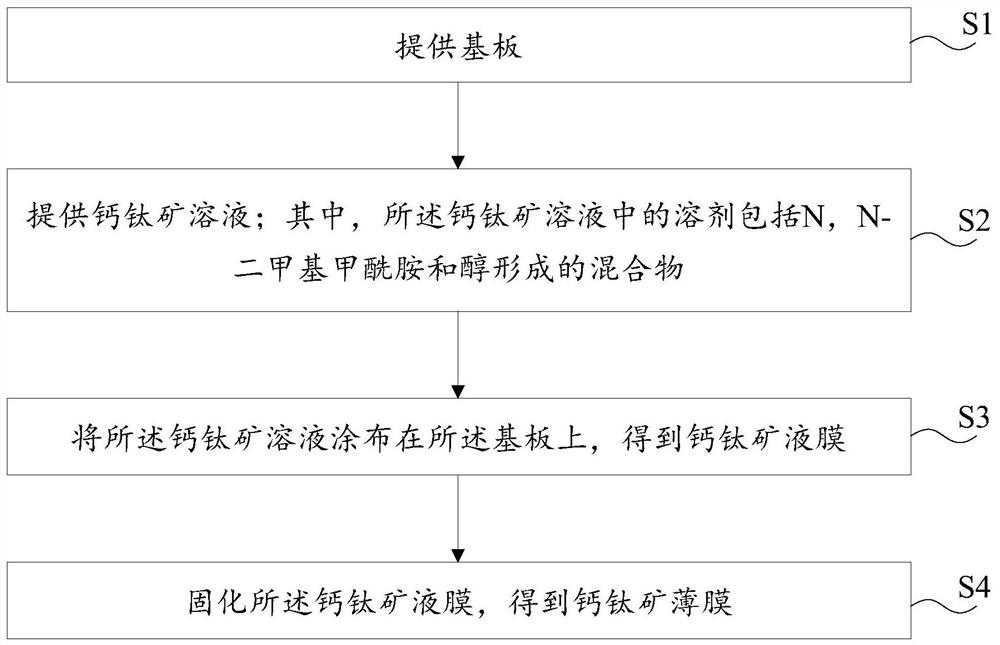

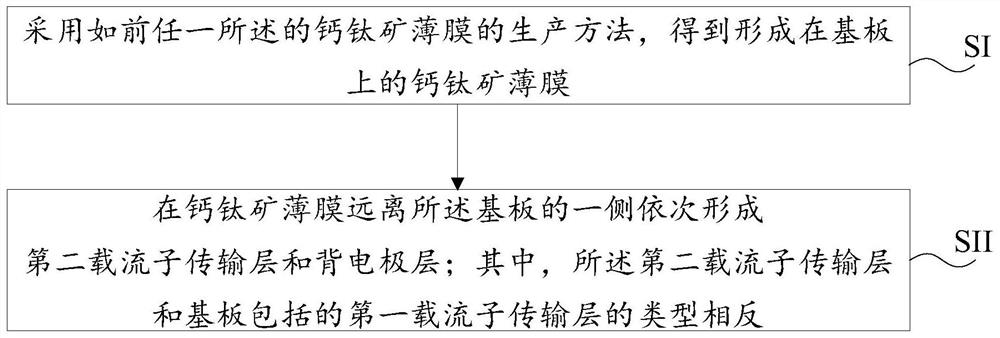

[0061] In the embodiment of the present invention, a method for preparing a perovskite battery is also provided, referring to image 3 As shown,. image 3 A flow chart of the steps of a method for preparing a perovskite solar cell in an embodiment of the present invention is shown. The method comprises the steps of:

[0062] SI, using the production method of the perovskite film as described in any one of the preceding, to obtain the perovskite film formed on the substrate.

[0063] SII, forming a second carrier transport layer and a back electrode layer sequentially on the side of the perovskite film away from the substrate; wherein, the second carrier transport layer and the first carrier transport layer included in the substrate type is reversed.

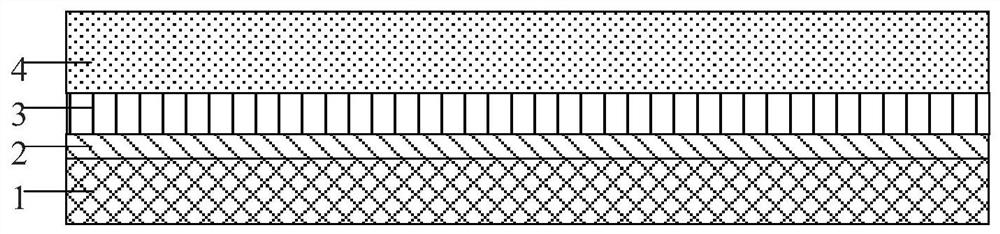

[0064] According to the preparation method of the above-mentioned perovskite battery can be as follows Figure 4 as shown, Figure 4 A schematic structural view of a perovskite solar cell in an embodiment of the present inve...

Embodiment 1

[0068] The production method of perovskite solar cell comprises steps SA1-SA5:

[0069] Step SA1, providing transparent conductive glass, and cleaning the transparent conductive glass.

[0070] Specifically, the transparent conductive glass was ultrasonically cleaned with detergent, deionized water, absolute ethanol, acetone, and isopropanol in sequence for 10 minutes (minutes), and then blown dry with nitrogen. The transparent conductive glass is a combination of the substrate and the front electrode layer, and one side of the conductive glass has the front electrode layer.

[0071] Step SA2, preparing a hole transport layer on the side of the transparent conductive glass with the front electrode layer.

[0072] Specifically, the hole transport layer is NiMgO x , it should be noted that x in the chemical formula can be selected by those skilled in the art according to the actual situation. Configure a mixture of nickel acetylacetonate and magnesium acetate dihydrate, where...

Embodiment 2

[0080] The production method of the perovskite solar cell comprises steps SB1-SB5:

[0081] Step SB1, providing transparent conductive glass, and cleaning the transparent conductive glass.

[0082] Step SB2, preparing a hole transport layer on the side of the transparent conductive glass with the front electrode layer.

[0083] The steps SB1 to SB2 are respectively the same as the aforementioned SA1 - SA2 , and will not be repeated here in order to avoid repetition.

[0084] Step SB3, preparing a perovskite thin film on the side of the hole transport layer away from the front electrode layer.

[0085] Specifically, under the protection of nitrogen, the perovskite thin film is prepared on the side of the hole transport layer away from the front electrode layer or the transparent conductive glass by scraping in the coating method. Equimolar PbI 2 and CH 3 NH 3 I was co-dissolved in a mixture of DMF and ethanol, the volume ratio of DMF and ethanol was 4:1 to obtain a 0.5 mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com