Zirconium alloy ingot casting alloy element adding method

A technology of alloying elements and zirconium alloys, which is applied in the field of adding alloy elements to zirconium alloy ingots, can solve the problems of heavy weighing workload and data recording, sticking tungsten electrodes on the surface of alloy buckles, and inability to guarantee the uniformity of tin, etc. The effects of extending package performance, improving production efficiency, and avoiding quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment includes the following steps:

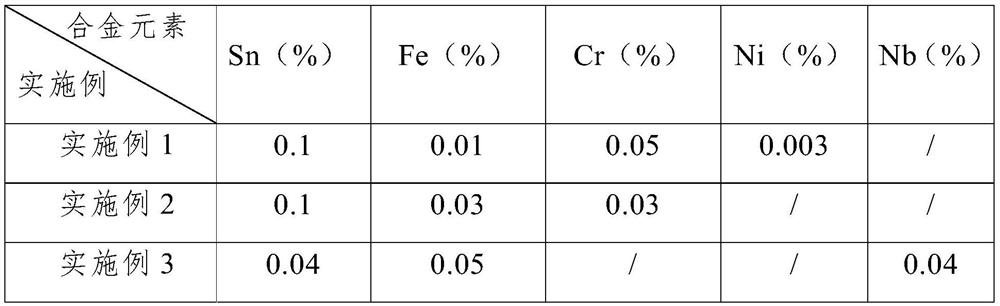

[0026] Step 1, material preparation: prepare 15kg tin particles, 1.3kg iron filings, 1.3kg Chromium particles, 0.6kg nickel foil, 3.5kg zirconium foil and 1056kg nuclear grade zirconium sponge;

[0027] Step 2. Preparation of intermediate alloy package: select and weigh the tin particles, iron filings, chromium particles and nickel foil prepared in step 1, then pour them into zirconium foil and wrap them into bags to ensure that the internal materials will not be exposed, and prepare intermediate Alloy ladle; the mass of a single intermediate alloy ladle is 221g, and the total number of intermediate alloy ladles is 98;

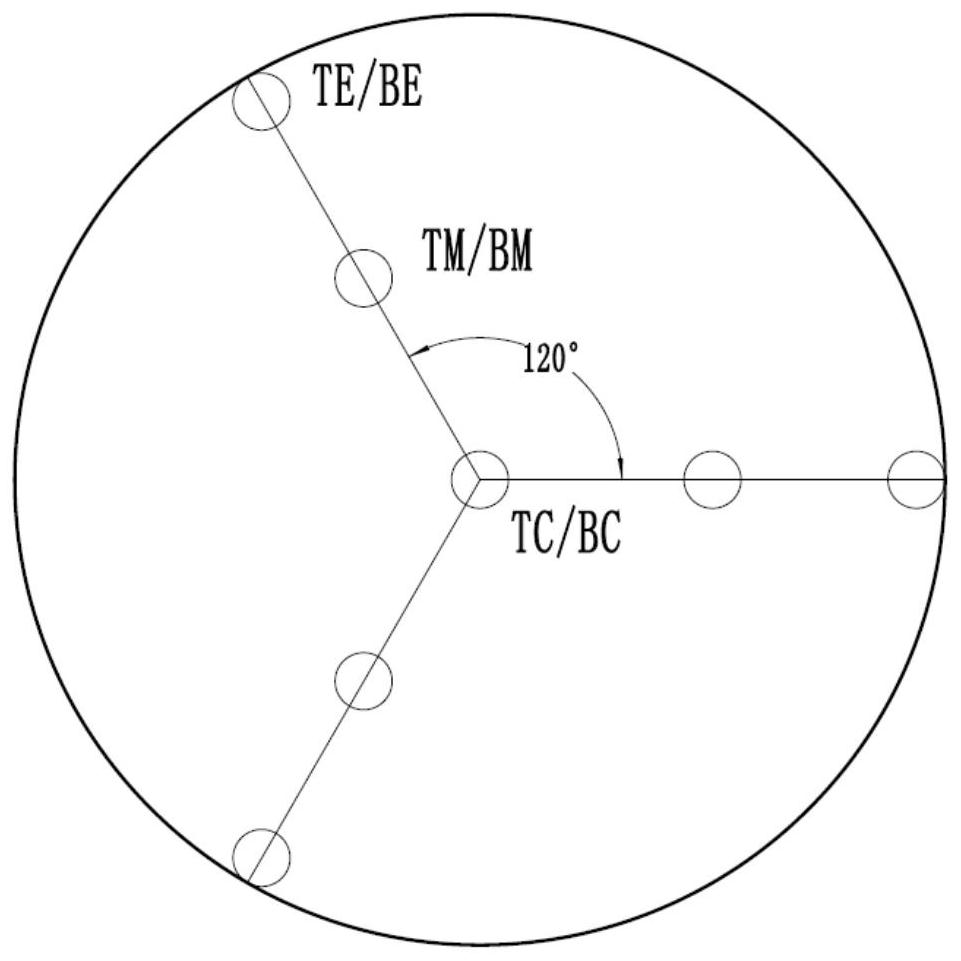

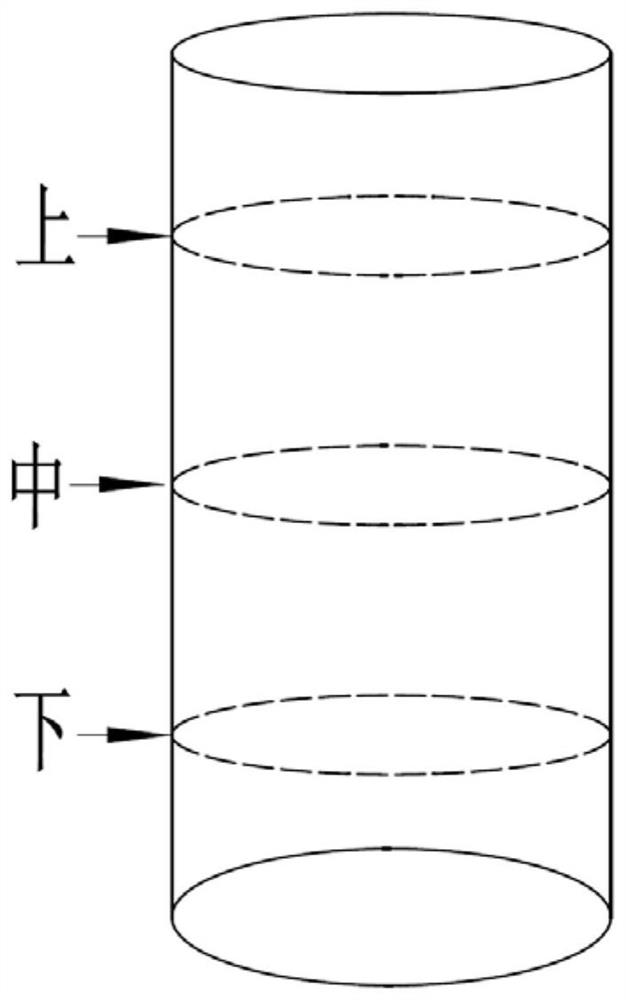

[0028] Step 3. Cloth: Lay the bottom layer of nuclear-grade zirconium sponge on the bottom of the electrode block mold, then place the 7 intermediate alloy bags prepared in step 2 at equal intervals on the bottom layer of nuclear-grade zirconium sponge, and then lay the top layer of nuclear-grade zirconiu...

Embodiment 2

[0032] This embodiment includes the following steps:

[0033] Step 1, material preparation: prepare 41.6kg tin particles, 5.6kg iron filings, and 3.9kg chromium particles according to the composition and content of each component in the target product Zr-4 (Zr-1.5Sn-0.2Fe-0.1Cr) zirconium alloy ingot , 6.9kg of zirconia powder, 7.0kg of zirconium foil and 3015kg of nuclear-grade zirconium sponge;

[0034] Step 2. Preparation of the intermediate alloy bag: select and weigh the tin particles, iron filings, chromium particles and zirconia powder prepared in step 1, then pour them into zirconium foil and wrap them into bags to ensure that the internal materials will not be exposed. Prepare Obtain an intermediate alloy bag; the quality of a single said intermediate alloy bag is 324g, and the quantity of the intermediate alloy bag is 200 in total;

[0035] Step 3. Cloth: Lay the bottom layer of nuclear-grade zirconium sponge on the bottom of the electrode block mold, then place the...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Step 1, material preparation: Prepare 9kg tin foil, 3kg iron filings, 2.1kg zirconium dioxide powder, 27kg zirconium-niobium alloy scraps according to the composition and content of each component in the target product Zr-1.0Sn-1.0Nb-0.3Fe zirconium alloy ingot , 1.9kg zirconium foil and 1035kg nuclear-grade zirconium sponge;

[0041] Step 2. Preparation of the intermediate alloy bag: select and weigh the iron filings and tin foil prepared in step 1, then pour the iron filings into the tin foil and wrap them into a bag with zirconium foil, and ensure that the internal materials will not be exposed. The prepared Intermediate alloy ladle; the mass of a single intermediate alloy ladle is 248g, and the total number of intermediate alloy ladles is 56;

[0042] Step 3. Cloth: Lay the bottom layer of nuclear-grade zirconium sponge on the bottom of the electrode block mold, then place the 4 intermediate alloy bags prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com