Method for simultaneously detecting three monoglyceride emulsifiers in dairy product based on gas chromatography-mass spectrometry

A technology of gas chromatography and dairy products, applied in the field of simultaneous detection of three monoglyceride emulsifiers in dairy products, which can solve the problems of low detection sensitivity and complicated processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

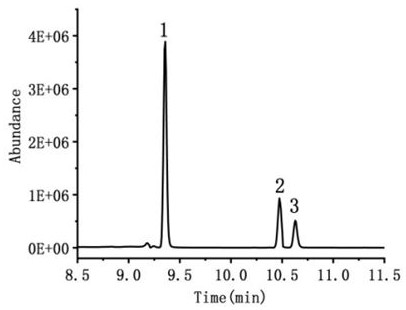

[0020] Gas chromatography-mass spectrometry (USA, Agilent Corporation), including 7080B chromatographic system, 5977MSD and NIST spectral retrieval library. Chromatographic conditions: chromatographic column: HP-5MS capillary column; heating program: initial temperature is 60 °C, rising to 270 °C at 30 °C / min, rising to 285 °C at 3 °C / min; carrier gas: high-purity helium; flow rate: 1.0 mL / min; injection volume: 1.0 μL; split ratio: 10:1; inlet temperature: 250 °C. Mass spectrometry conditions: electron bombardment (EI) ion source; electron energy: 70 eV; ion source temperature: 230 ℃; quadrupole temperature: 150 ℃; solvent delay: 6.5 min; acquisition method: selected ion scanning. The mass spectrometric detection parameters of the three target compounds are shown in Table 1.

Embodiment 2

[0022] CH in Dairy 2 Cl 2 The extract is used as a solvent, and a series of mass concentrations of glyceryl monopalmitate, glyceryl monooleate and glyceryl monostearate are prepared as a standard working solution of mixed matrix, and the silylating reagent N,O-bis(trimethylsilyl) After derivatization with trifluoroacetamide (containing trimethylchlorosilane) (BSTFA+1%TMCS), the analysis was carried out under the above chromatographic and mass spectrometric conditions, and the peak area (y) was used to perform linear regression on the analyte concentration (x). The equation, detection limit and quantification limit are shown in Table 2.

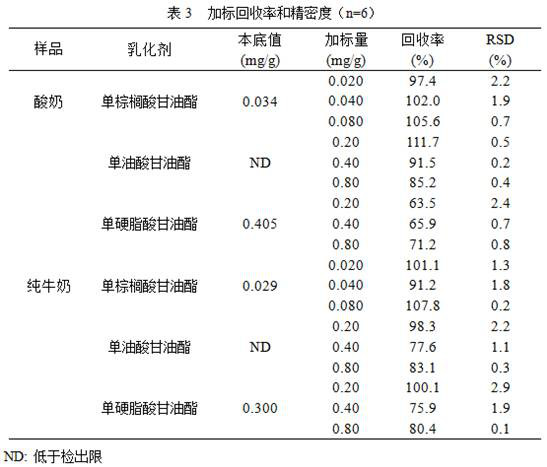

Embodiment 3

[0024] Sample pretreatment: Accurately weigh about 0.5 g of milk sample, add 5.0 mL of water and mix well; add 10.0 mL of CH 2 Cl 2 For extraction, shake for 10 min. Centrifuge at 13000 r / min for 10 min, and collect the lower organic phase. Then add 10.0mLCH 2 Cl 2 The above extraction steps were repeated, and the organic phases were combined. Take 1.0 mL of extract liquid and dry it with nitrogen gas, add 50 μL of pyridine to dissolve; then add 100 μL of silylating reagent N,O-bis(trimethylsilyl)trifluoroacetamide (containing trimethylchlorosilane) (BSTFA+1% TMCS), react at 70 °C for 40 min, and dilute to 1.0 mL with n-heptane to obtain the upper machine solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com