Bactericide for offshore oilfield reinjection water and preparation method thereof

An offshore oilfield and water reinjection technology, which is applied in the direction of fungicides, botanical equipment and methods, biocides, etc., can solve the problems of ineffective control and killing of microorganisms in oil-water systems, increasing the amount of fungicides, and bacterial resistance, etc. problem, to achieve the effect of good water solubility, good synergistic effect, and small foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

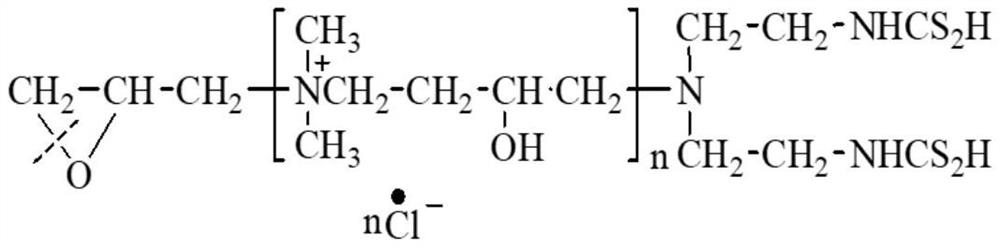

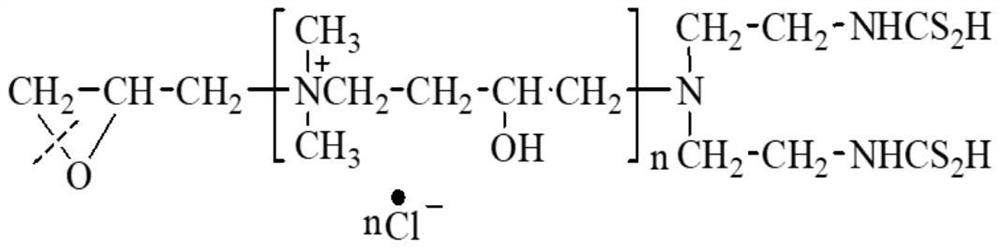

Method used

Image

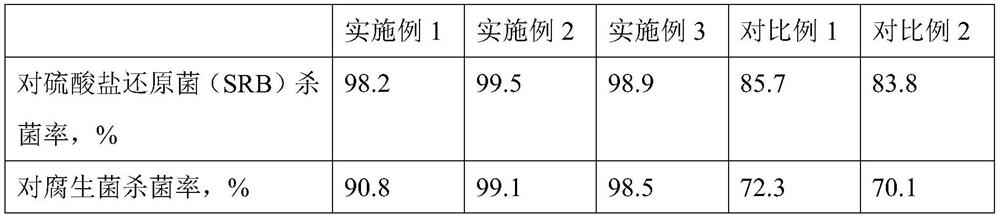

Examples

Embodiment 1

[0025] A fungicide for reinjection water in offshore oilfields, the following raw materials are obtained in parts by mass: 4 g of trimethylamine, 4 g of epichlorohydrin; 4 g of diethylene triamine; 6 g of carbon disulfide; 12 g of tetrakis hydroxymethyl phosphorus sulfate; 6 g of glutaraldehyde ; Benzotriazole 2g; Ethanol 6g; Water 156g.

[0026] Concrete preparation method steps are as follows:

[0027] (1) In a four-necked flask with a stirring and reflux condenser, first add diethylenetriamine aqueous solution, start the agitator, cool in an ice-water bath, and cool the diethylenetriamine aqueous solution to below 20°C; turn on the reflux To the cooling water of the condenser, under the condition of stirring, add carbon disulfide dropwise with a separatory funnel. Strengthen the cooling, so that the temperature in the reactor is controlled at 20-25 °C, and the entire dropping time is about 2 hours. After the addition, the temperature was raised to reflux and reacted for 5...

Embodiment 2

[0031] A kind of fungicide for reinjection water in offshore oil field, the raw materials of the following mass fractions are taken: trimethylamine 6g, epichlorohydrin 9g; Diethylenetriamine 3g; Carbon disulfide 10g; Tetrahydroxymethyl phosphorus sulfate 40g; Glutaraldehyde 10g ; Benzotriazole 5g; Ethanol 10g; Water 127g.

[0032] Concrete preparation method comprises steps as follows:

[0033] (1) In a four-necked flask with a stirring and reflux condenser, first add diethylenetriamine aqueous solution, start the agitator, cool in an ice-water bath, and cool the diethylenetriamine aqueous solution to below 20°C; turn on the reflux To the cooling water of the condenser, under the condition of stirring, add carbon disulfide dropwise with a separatory funnel. Strengthen the cooling so that the temperature in the reactor is controlled at 25-30°C, and the entire dropping time is about 2 hours. After the addition, the temperature was raised to reflux and reacted for 6 hours until...

Embodiment 3

[0037] A fungicide for reinjection water in offshore oilfields, the following raw materials are obtained in parts by mass: 8 g of trimethylamine, 8 g of epichlorohydrin; 6 g of diethylenetriamine; 16 g of carbon disulfide; 50 g of tetrakis hydroxymethyl phosphorus sulfate; 10 g of glutaraldehyde ; Benzotriazole 2g; Ethanol 12g; Water 88g.

[0038] The preparation method steps are as follows:

[0039](1) In a four-neck flask with a stirring and reflux condenser, first add diethylenetriamine aqueous solution, start the agitator, cool in an ice-water bath, and cool the diethylenetriamine aqueous solution to below 20°C; turn on the reflux To the cooling water of the condenser, under the condition of stirring, add carbon disulfide dropwise with a separatory funnel. Strengthen the cooling so that the temperature in the reactor is controlled at 25-30°C, and the entire dropping time is about 2 hours. After the addition, the temperature was raised to reflux and reacted for 6 hours un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com