Metal powder storage system and using method thereof

A storage system and metal powder technology, applied in the field of material storage, can solve the problems of difficult access and difficult storage of alloy powder, and achieve the effect of improving safety and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

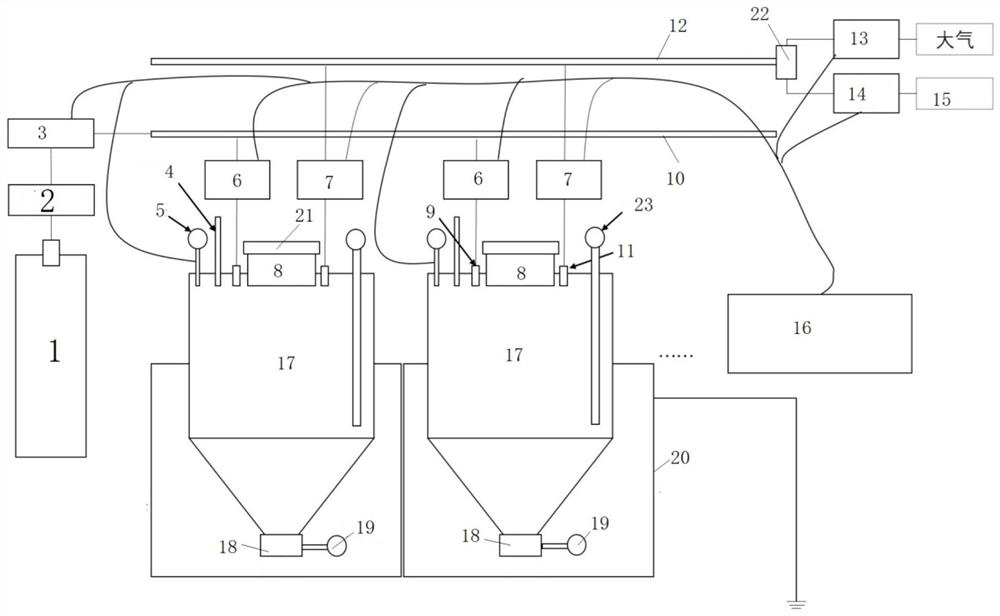

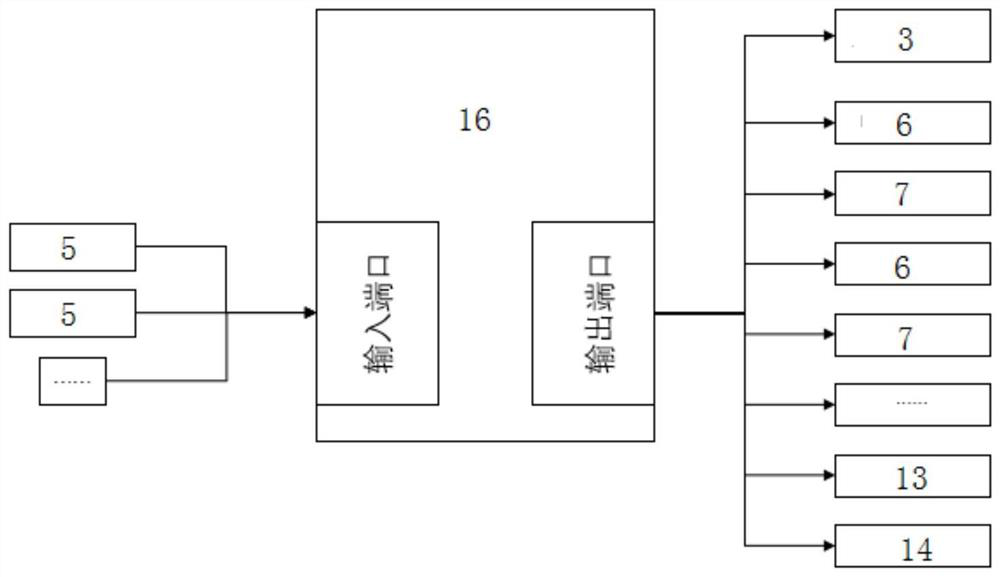

[0060] The frame 20 is made of steel welded or bolted, and is connected to the ground through bolts; the material of the storage tank 17 is stainless steel, the typical size of the storage tank is Φ500mm*500mm, the diameter of the material inlet 8 is 100mm, and the diameter of the material outlet 18 is 50mm. The diameter of the air inlet 9 and the air outlet 11 is Φ8mm, and a quick-plug connector is reserved, which is connected to the corresponding solenoid valve through a hose; the detection port 4 is a standard industrial valve core with a diameter of 5mm, which can be connected to the oxygen sensor, thereby Quickly measure the oxygen content in the storage tank; the pressure gauge 5 is an industrial pressure sensor with a head, the maximum detection pressure is 500mbar, and the detection accuracy is 0.15%. The signal transmits the detection result to the central logic controller 16; the argon gas bottle is connected to the pressure reducing valve 2 to decompress the high-pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com