Method for recycling fluorine-containing waste liquid

A technology of waste liquid and fluorosilicic acid, which is applied in the directions of hydrogen fluoride, fluorine/hydrogen fluoride, nitrogen oxides/oxyacids, etc., can solve the problem of no recycling of fluorine resources, and achieves low cost, simple treatment method and high recovery efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

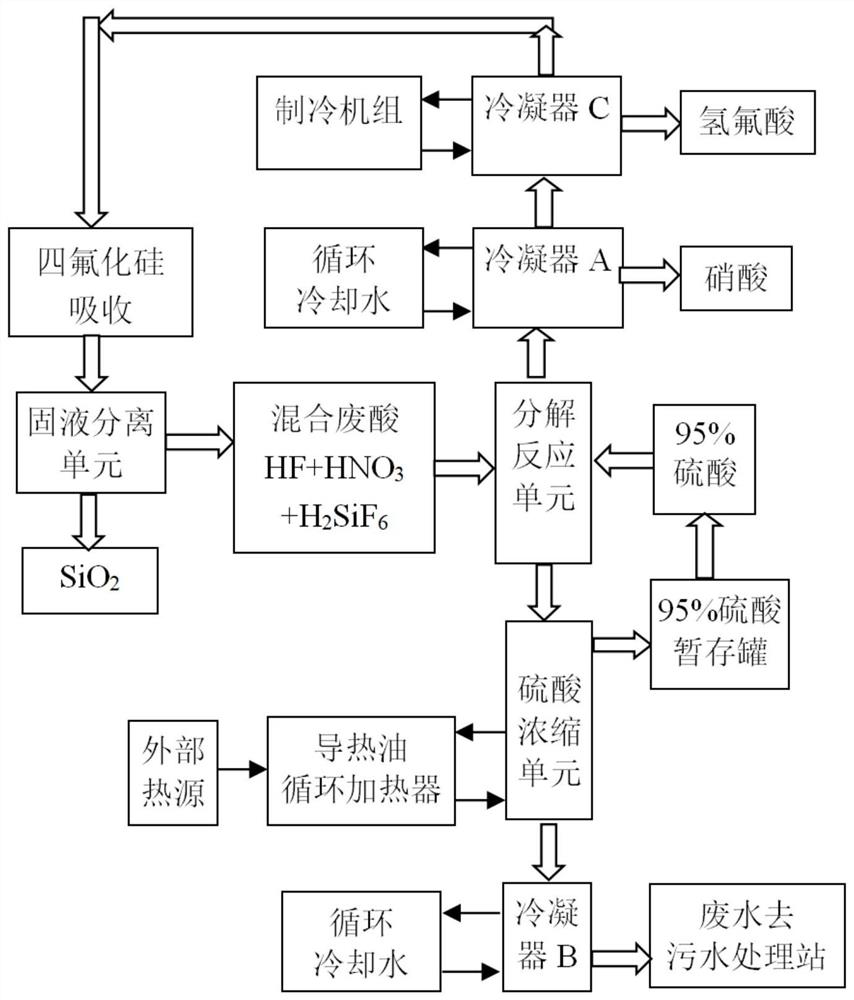

[0028] A method for recycling fluorine-containing waste liquid, comprising:

[0029] Add 1000kg of fluorine-containing waste acid into the stirred reactor, and simultaneously open condenser A (control cooling temperature 30°C) and condenser C (control cooling temperature -5°C); slowly and uniformly add 1450kg of 95% concentrated Sulfuric acid was added while stirring, and the temperature of the reaction kettle was displayed as 120°C. Hydrogen fluoride, silicon tetrafluoride, and nitric acid vapor escape in the form of gas; the output of condenser A is 436.2 kg of nitric acid, and the output of condenser C is 103.1 kg of hydrofluoric acid. Silicon tetrafluoride is absorbed with water to become concentrated fluorosilicic acid and silicon dioxide. After the silicon dioxide is separated, the remaining concentrated fluorosilicic acid is mixed with fluorine-containing waste liquid and continues to enter the system for treatment.

[0030] The above used concentrated sulfuric acid be...

Embodiment 2

[0033] A method for recycling fluorine-containing waste liquid, comprising:

[0034] Add 1000kg of fluorine-containing waste acid into the stirred reactor, and simultaneously open condenser A (control cooling temperature 30°C) and condenser C (control cooling temperature -5°C); slowly and uniformly add 1250kg of 95% concentrated Sulfuric acid was added while stirring, and the temperature of the reaction kettle was displayed as 112°C. Hydrogen fluoride, silicon tetrafluoride, and nitric acid vapor escape in the form of gas; the output of condenser A is 425.1 kg of nitric acid, and the output of condenser C is 102.9 kg of hydrofluoric acid. Silicon tetrafluoride is absorbed with water to become concentrated fluorosilicic acid and silicon dioxide. After the silicon dioxide is separated, the remaining concentrated fluorosilicic acid is mixed with fluorine-containing waste liquid and continues to enter the system for treatment.

[0035] The above used concentrated sulfuric acid be...

Embodiment 3

[0038] A method for recycling fluorine-containing waste liquid, comprising:

[0039] Add 1000kg of fluorine-containing waste acid to the stirred reactor, and simultaneously open condenser A (control the cooling temperature at 30°C) and condenser C (control the cooling temperature at -5°C); slowly and uniformly add 1100kg of 95% concentrated Sulfuric acid was added while stirring, and the temperature of the reaction kettle was displayed as 105°C. Hydrogen fluoride, silicon tetrafluoride, and nitric acid vapor escape in the form of gas; the output of condenser A is 419.6 kg of nitric acid, and the output of condenser C is 102.8 kg of hydrofluoric acid. Silicon tetrafluoride is absorbed with water to become concentrated fluorosilicic acid and silicon dioxide. After the silicon dioxide is separated, the remaining concentrated fluorosilicic acid is mixed with fluorine-containing waste liquid and continues to enter the system for treatment.

[0040] The above used concentrated sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com