Catalytic functional ceramic membrane as well as preparation method and application thereof

A ceramic membrane and functional technology, applied in the field of catalytic functional ceramic membrane and its preparation, can solve the problems of catalyst agglomeration, low flux of ceramic membrane, low content of active components, etc., and achieve improved catalytic efficiency, high catalytic activity, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

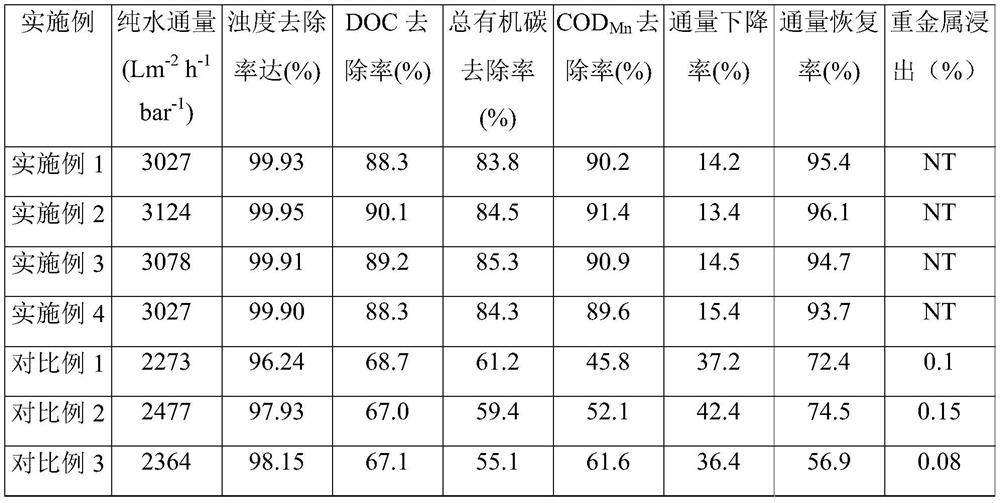

Examples

preparation example Construction

[0015] In a first aspect, the present invention provides a method for preparing a catalytic functional ceramic membrane, the method comprising the following steps:

[0016] (1) Preparation of catalytically active particles: using a metal-organic framework compound as a carrier to prepare an inverse microemulsion containing an active catalyst, after demulsification by a demulsifier, the active catalyst is supported on the carrier, and the separated precipitate is separated and dried , to produce catalytically active particles;

[0017] (2) Preparation of ceramic membrane blend: blending ceramic membrane raw material powder, hydroxymethyl cellulose, polyethylene glycol, the catalytically active particles and water to obtain a ceramic membrane blend;

[0018] (3) Preparation of the mixed mud: mixing the ceramic membrane blend and leaving it to stand to obtain the mixed mud;

[0019] (4) Forming of sintered preform: molding the mixed mud into a sintered preform;

[0020] (5) Sin...

Embodiment 1

[0048] The method for preparing a catalytic functional ceramic membrane in this embodiment comprises the following steps:

[0049] (1) Preparation of catalytically active particles: UiO-66 is used as a carrier for catalytically active molecules; the active catalyst is prepared by the reverse microemulsion method, wherein the continuous phase is n-hexane, and the surfactant is CTAB (cetyltrimethyl bromide ammonium), n-butanol as a stabilizer, water as a dispersed phase, adding Ce(NO 3 ) 3 6H 2 O and Fe(NO 3 ) 3 9H 2 After stirring the aqueous solution of O to form a stable microemulsion, add an appropriate amount of ammonia water to adjust the pH to 10, add a small amount of tetrahydrofuran and 1g / L UiO-66 to load, after breaking the emulsion, wash it repeatedly with water for 3 times, dry it, and grind it with a ball mill Become a 500-mesh particle to obtain an active catalyst;

[0050] (2) Preparation of ceramic membrane blends: select Al 2 o 3 As a ceramic matrix, th...

Embodiment 2

[0056] The method is basically the same as in Example 1, except that a zeolite imidazolate framework material (ZIF) is used instead of a Zr-based metal-organic framework compound (UiO-66) as a metal-organic framework compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com