Novel biological filter sand and application thereof in quicksand filter

A quicksand filter and biological filtration technology, applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of difficult to achieve up and down suspension movement, inability to fully absorb pollutants in water, and lack of physical filtration function. and other problems, to achieve the effect of easy promotion, easy microbial load and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

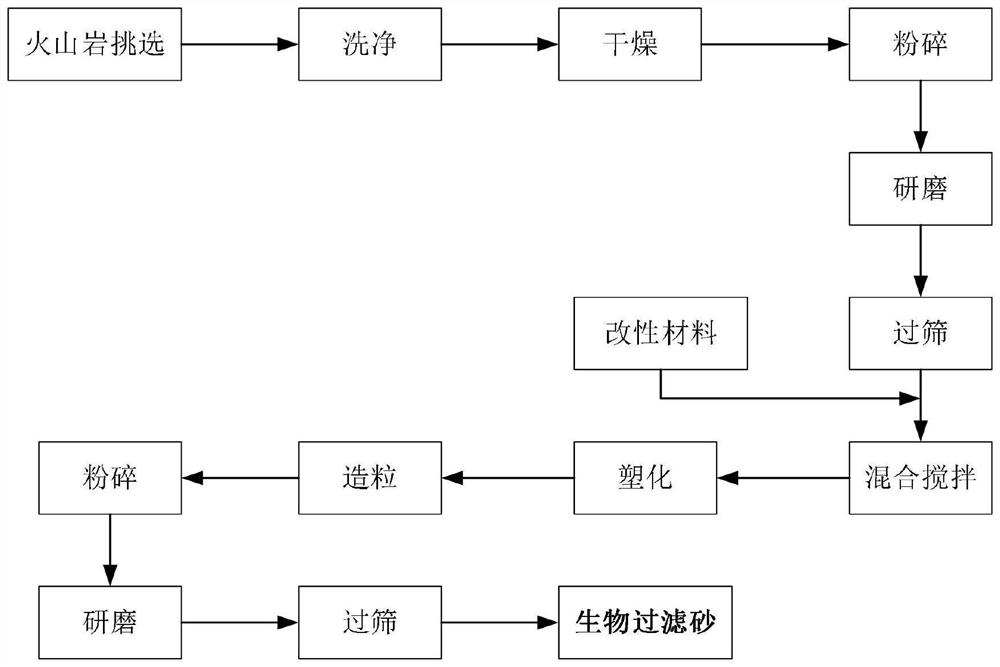

[0047] A kind of novel biological filter sand, its preparation method comprises the steps:

[0048] (1) Pre-treatment of volcanic rocks: Take volcanic rocks, wash them with clean water, dry them, crush them with a hammer crusher, and then grind them with a micro-powder mill. The particle size of volcanic rocks after grinding is 1.6~ 40um, and then use ultrasonic vibrating sieving sieve, the particle size of volcanic rock after sieving is 3-10um, and the specific gravity is 0.70-0.80;

[0049] (2) get the volcanic rock and modified material stirring and mixing (the volcanic rock content of gaining after pretreatment is 55wt% after pretreatment in the step (1), modified material content is 45wt%); Modified material used is by following Mixed raw materials: 100 parts by weight of LDPE, 0.35 parts by weight of zinc stearate, 0.3 parts by weight of LDTPE, 0.3 parts by weight of lubricant, 3 parts by weight of EVA, 1 part by weight of foaming agent and CaCO 3 400 parts by weight; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap