Underwater non-diffusion concrete and preparation method thereof

A concrete and cement technology, applied in the field of concrete, can solve the problems of concrete quality decline, environmental pollution, efflorescence, etc., and achieve the effects of improving compactness, avoiding efflorescence, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

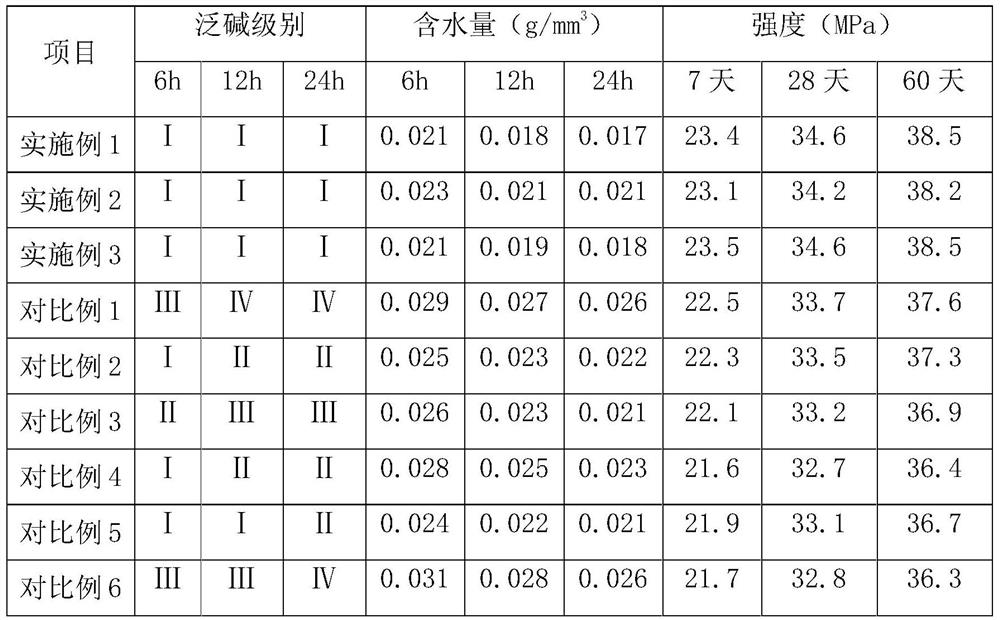

Examples

Embodiment 1

[0037] Embodiment 1: a kind of underwater non-diffusion concrete is prepared by the following method:

[0038] S1, weigh 430kg of cement, 845kg of sand, 900kg of stones, 205kg of water, 12.9kg of sodium rosin, 8kg of ammonium chloride, 2kg of triethanolamine, 2kg of calcium nitrite, 12kg of silica fume, 2kg of polyacrylamide, and naphthalene-based high-efficiency water reducing agent agent 2kg; cement is P, O42.5 ordinary Portland cement; sand is medium sand, fineness modulus 2.7-2.9; stone is crushed stone, and the particle size of crushed stone is 5-31.5mm;

[0039] S2, place sand and stone in the stirring kettle and stir for 25s at a speed of 150r / min to obtain mixture A;

[0040] S3, put cement, polyacrylamide, triethanolamine and ammonium chloride in a new mixer and stir at a speed of 150r / min for 5min, after stirring evenly, pour into the mixture A prepared by S1, and add silica fume and 123kg water, continue to stir at a speed of 150r / min for 2min to prepare mixture B;...

Embodiment 2

[0042] Embodiment 2: a kind of underwater non-diffusion concrete is prepared by the following method:

[0043] S1, weigh cement 410kg, sand 830kg, stone 870kg, water 200kg, sodium rosin 10kg, ammonium chloride 5kg, triethanolamine 1kg, calcium nitrite 1kg, silica fume 8kg, polyacrylamide 1kg, naphthalene-based superplasticizer 1kg; Cement is P,O42.5 ordinary Portland cement; Sand is medium sand, fineness modulus 2.7-2.9; Stone is crushed stone, and the particle size of crushed stone is 5-31.5mm;

[0044] S2, place sand and stone in the stirring kettle and stir for 25s at a speed of 100r / min to obtain mixture A;

[0045] S3, put cement, polyacrylamide, triethanolamine and ammonium chloride in a new mixer and stir at a speed of 100r / min for 5min, stir evenly and pour into the mixture A prepared by S1, and add silica fume and 120kg water, continue to stir at a speed of 100r / min for 2min to prepare mixture B;

[0046] S4. Add sodium rosin, calcium nitrite, polyacrylamide, naphth...

Embodiment 3

[0047] Embodiment 3: a kind of underwater non-diffusion concrete is prepared by the following method:

[0048] S1, weigh cement 450kg, sand 860kg, stone 920kg, water 210kg, sodium rosin 15kg, ammonium chloride 10kg, triethanolamine 5kg, calcium nitrite 5kg, silica fume 14kg, polyacrylamide 3kg, naphthalene-based superplasticizer 3kg; Cement is P,O42.5 Ordinary Portland Cement; Sand is medium sand, fineness modulus is 2.7-2.9; Stone is crushed stone, and the particle size of crushed stone is 5-31.5mm;

[0049] S2, place sand and stone in the stirring kettle and stir for 25s at a speed of 200r / min to obtain mixture A;

[0050] S3, put cement, polyacrylamide, triethanolamine and ammonium chloride in a new mixer and stir at a speed of 220r / min for 5min, stir evenly and pour into the mixture A prepared by S1, and add silica fume and 126kg water, continue to stir for 2min at a speed of 220r / min to prepare mixture B;

[0051] S4. Add sodium rosin, calcium nitrite, polyacrylamide, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com