Antistatic polyester film and preparation method thereof

A polyester film, antistatic technology, applied in conductive coatings, coatings, etc., can solve the problems of coatings not having antistatic properties, adsorbing impurities, affecting the appearance of the film, etc., to achieve stable distribution, crosslinking degree and other problems Increase and improve the effect of scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 60g of ethanol, 40g of deionized water and mix evenly at high speed, then add 4.5g of 1314-13-2, 7.5g of 7631-86-9, 3g of UG-T15ST, 0.075g of γ-methacryloxypropylmethyl Diethoxysilane, 0.15g γ-methacryloxypropyltrimethoxysilane, 0.075g γ-methacryloxypropylmethyldimethoxysilane, reacted at 30°C for 3 hours, Finally, the modified nano inorganic particles are obtained by ethanol washing, vacuum drying and grinding.

[0039] Weigh 12g modified nano-inorganic particles, 10g methyl methacrylate, 35g lauryl acrylate, 35g n-octyl acrylate, 6g acrylic acid, react at 70°C for 3 hours, then add 2g ISCP-50, The heat preservation was continued for 1 hour, and finally the synthesized resin was cooled to room temperature to obtain a hybrid acrylate resin.

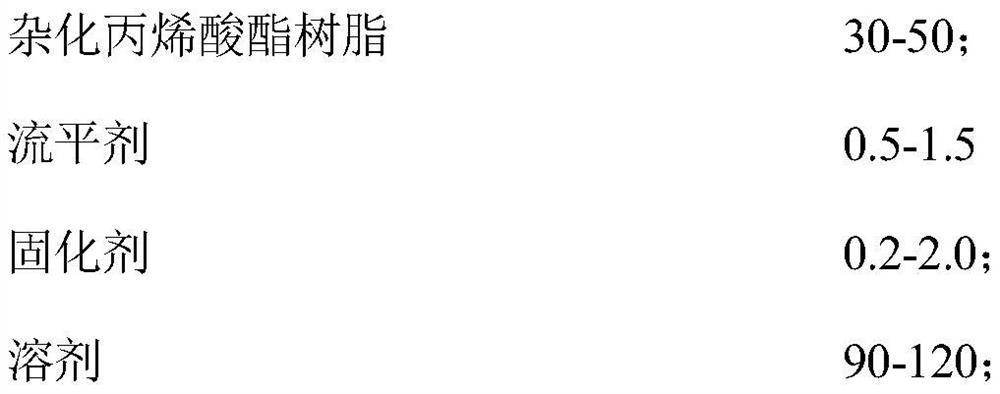

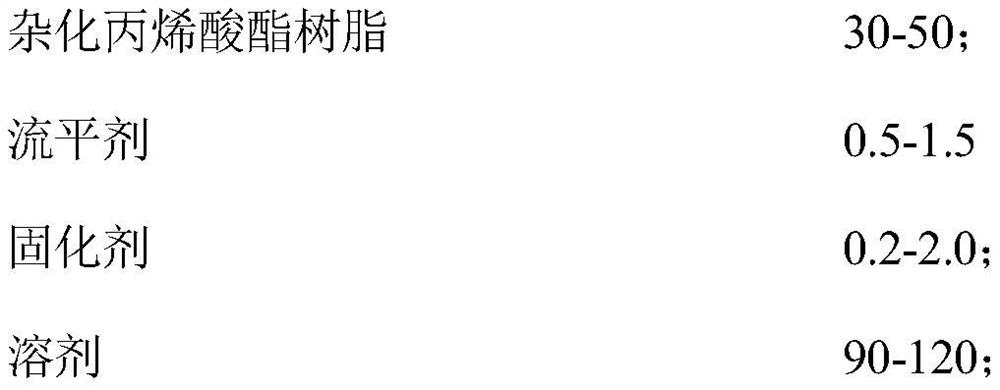

[0040] Weigh 30g of the above-mentioned hybrid acrylate resin, 0.5g BYK346, 0.2g hexahydroxymelamine resin, 60g isopropanol and 30g deionized water, and mix them uniformly to obtain an antistatic coating solution, which is c...

Embodiment 2

[0043] Weigh 100g of ethanol and 100g of deionized water and mix them evenly at high speed, then add 7.5g of 14808-60-7, 0.1g of γ-methacryloxypropyltrimethoxysilane, and react at 50°C for 1.5 hours. Finally, the modified nano inorganic particles are obtained by ethanol washing, vacuum drying and grinding.

[0044]Weigh 4g of modified nano-inorganic particles, 10g of methyl methacrylate, 10g of methyl acrylate, 50g of n-octyl acrylate, 3g of methacrylic acid, 10g of acrylic acid, and 5g of hydroxyethyl acrylate, and react at 75°C for 3.5 hours. Then add 4g of ISCP-50 and 4g of BZD-CP-BM, continue to keep warm at 45°C for 1 hour, and finally cool the synthesized resin to room temperature to obtain a hybrid acrylate resin.

[0045] Weigh 50g of the above-mentioned hybrid acrylate resin, 0.3g BYK346, 0.5g BYK333, 0.5g hexahydroxymelamine resin, 0.6g methylated melamine resin, 30g ethanol, 40g isopropanol, 20g n-butanol and 30g deionized water, mix After being uniform, an antista...

Embodiment 3

[0048] Weigh 60g of ethanol and 90g of deionized water and mix evenly at high speed, then add 5.07g of MG-ZnO-30, 5.93g of 7631-86-9, 0.05g of γ-methacryloxypropylmethyldiethoxysilane , 0.01g of γ-methacryloxypropyltrimethoxysilane, reacted at 40°C for 1.9 hours, and finally washed with ethanol, vacuum dried and ground to obtain modified nano-inorganic particles.

[0049] Weigh 6g of modified nano-inorganic particles, 9g of methyl methacrylate, 6g of methyl acrylate, 40g of lauryl acrylate, 20g of n-octyl acrylate, 7g of acrylic acid, and 8g of hydroxyethyl acrylate, and react at 80°C for 3 hours. Then add 3g of ISCP-50 and 1g of BZD-CP-BM, keep warm at 40°C for 1.5 hours, and finally cool the synthesized resin to room temperature to obtain a hybrid acrylate resin.

[0050] Weigh 40g of the above-mentioned hybrid acrylate resin, 0.8g BYK346, 0.7g BYK333, 1g hexahydroxymelamine resin, 0.5g methylated melamine resin, 55g ethanol and 55g deionized water, and mix them uniformly to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com