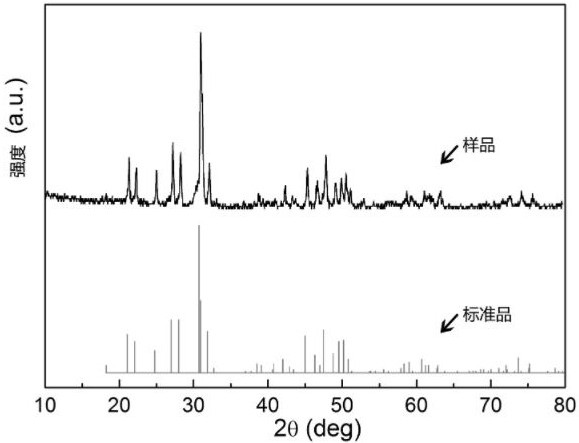

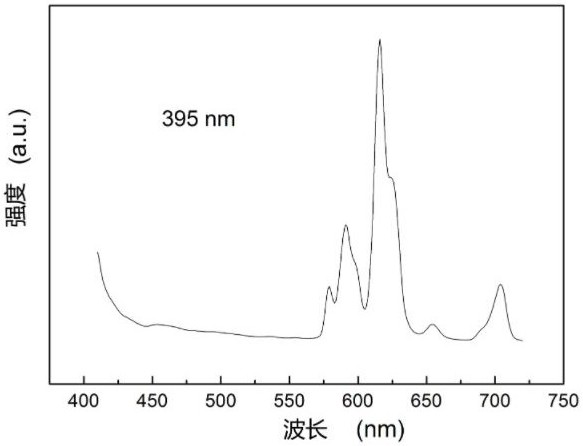

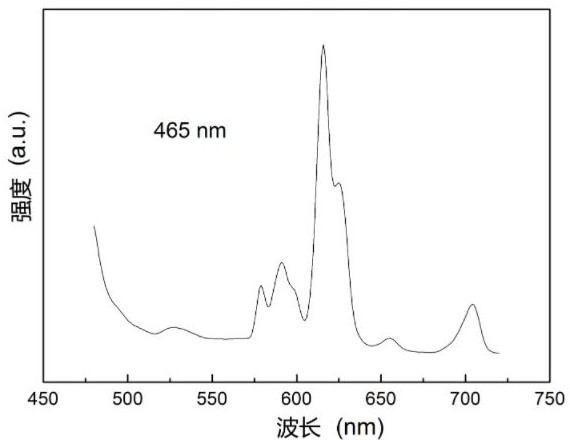

Apatite structure lanthanum silicate luminescent powder material as well as preparation method and application thereof

A technology of luminescent powder and lanthanum silicate, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of low sintering temperature, long time, complicated process, etc., and achieve simple preparation process, low cost, and overcome phase formation The effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of apatite type lanthanum silicate luminescent powder material, comprising the following steps:

[0031] (1) Weigh lanthanum nitrate, europium nitrate, calcium carbonate and magnesium nitrate according to the chemical molar ratio of 8:1:2:0, add the above raw materials into deionized water, fully stir and dissolve to become a transparent solution;

[0032] (2) Ethyl orthosilicate is added to the transparent solution obtained in step (1), the molar ratio of ethyl orthosilicate to lanthanum nitrate is 6:8 to obtain a precursor solution;

[0033] (3) Take deionized water, ammonia water and absolute ethanol at a volume ratio of 1:1:1, mix them, adjust the pH value to 9, and obtain a precipitant solution;

[0034] (4) Slowly drop the precursor solution obtained in step (2) into the precipitant solution obtained in step (3), stir with a magnetic stirrer, and adjust the pH value to 9 to obtain a white precipitate;

[0035] (5) Wash the white precipitate o...

Embodiment 2

[0038] A preparation method of apatite type lanthanum silicate luminescent powder material, comprising the following steps:

[0039] (1) Weigh lanthanum nitrate, europium nitrate, calcium carbonate and magnesium nitrate according to the chemical molar ratio of 7:1:2:1, add the above raw materials into deionized water, fully stir and dissolve to become a transparent solution;

[0040] (2) Ethyl orthosilicate was added to the transparent solution obtained in step (1), the molar ratio of ethyl orthosilicate to lanthanum nitrate was 6:7 to obtain a precursor solution;

[0041] (3) Take deionized water, ammonia water and absolute ethanol according to the volume ratio of 1:1:2, mix them, adjust the pH value to 8, and obtain the precipitant solution;

[0042](4) Slowly drop the precursor solution obtained in step (2) into the precipitant solution obtained in step (3), stir with a magnetic stirrer, and adjust the pH value to 8 to obtain a white precipitate;

[0043] (5) Wash the whit...

Embodiment 3

[0046] A preparation method of apatite type lanthanum silicate luminescent powder material, comprising the following steps:

[0047] (1) Weigh lanthanum nitrate, europium nitrate, calcium carbonate and magnesium nitrate according to the chemical molar ratio of 6:1:2:2, add the above raw materials into deionized water, fully stir and dissolve to become a transparent solution;

[0048] (2) Ethyl orthosilicate is added to the transparent solution obtained in step (1), the molar ratio of ethyl orthosilicate to lanthanum nitrate is 5:6 to obtain a precursor solution;

[0049] (3) Take deionized water, ammonia water and absolute ethanol according to the volume ratio of 1:2:2, mix them, adjust the pH value to 10, and obtain a precipitant solution;

[0050] (4) Slowly drop the precursor solution obtained in step (2) into the precipitant solution obtained in step (3), stir with a magnetic stirrer, and adjust the pH value to 10 to obtain a white precipitate;

[0051] (5) Wash the white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com