Method and system for preparing gasoline and diesel by mixing and hydrogenating coal tar and biomass oil

A technology for biomass oil and coal tar, which is applied in biological raw materials, biofuels, hydrotreating processes, etc., can solve the problems of difficult quality control, high hydrogen consumption and difficulty in hydrogenation reaction, and achieves the guarantee of hydrogen pressure state, Improved hydrogenation efficiency and little effect of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

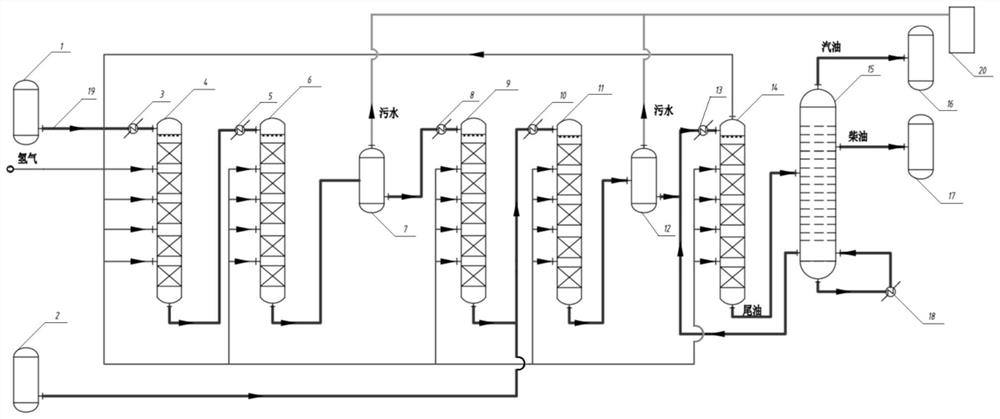

[0090] After the coal tar from the coal tar raw material tank is mixed with the hydrogen from the hydrogen pipeline, after heat exchange, it enters the first reactor, where the coal tar is mainly pretreated, and the main reaction is the hydrogenation saturation of olefins. Stream I is obtained at the outlet of the first reactor.

[0091] Stream I enters the second reactor through heat exchange, mainly for deoxygenation of reactants, and the main reaction is hydrodeoxygenation of oxygen-containing compounds. Feed II is obtained at the outlet of the second reactor.

[0092] Stream II enters the oil-water separation tank, and the separated sewage is sent to the sewage treatment plant, and the remaining reactants enter the third reactor through heat exchange, and the main reaction is hydrogenation and saturation of unsaturated hydrocarbons. Stream III is obtained at the outlet of the third reactor.

[0093] Stream III is mixed with the bio-oil from the bio-oil storage tank and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com