Method for producing rock wool by utilizing coal gangue

A technology of coal gangue and rock wool, which is applied in the field of continuous fiber material production, can solve problems such as difficulty in continuous production and high energy consumption, and achieve the effects of improved homogenization, low operating costs, and environmental protection in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for producing rock wool from coal gangue, comprising the following steps:

[0028] a) Weigh 60kg of coal gangue, 20kg of slag, 10kg of diatomite and 10kg of kaolin;

[0029] b) Calcining and melting the above raw materials into magma in the melting tank kiln;

[0030] c) spinning the magma through high-speed centrifugation, and spraying binder and water repellent at the same time to obtain fibers;

[0031] d) The fibers are collected, spread, pressed, solidified and cut into rock wool materials in sequence;

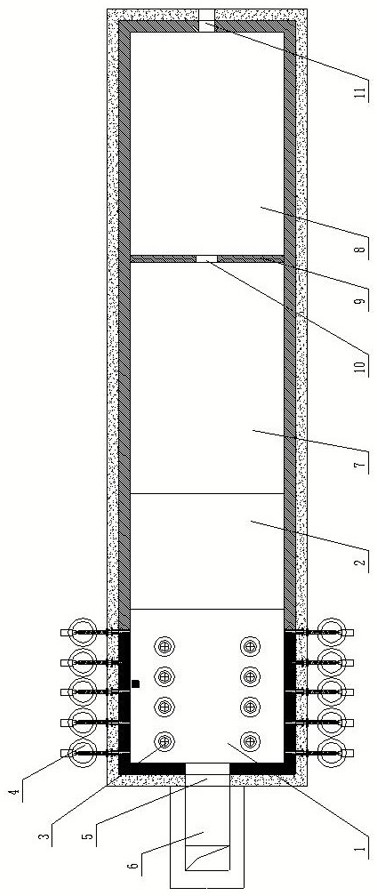

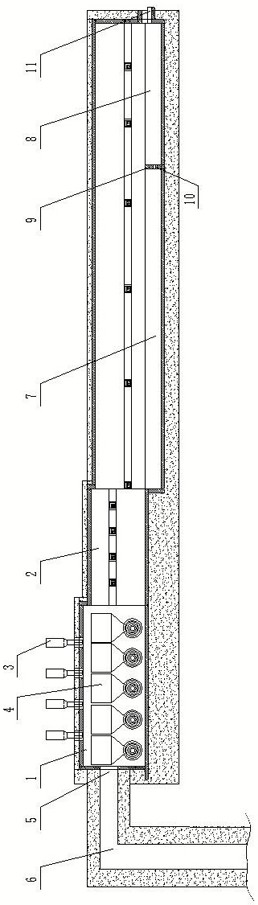

[0032] Such as figure 1 with 2 As shown, the melting tank kiln includes a calcining section and a melting pool. The calcining section includes a calcining front section 1 and a calcining post section 2. The molten pool is arranged at the tail of the calcining post section 2, and the outlet of the calcining front section 1 is higher than the calcining post section 2. The feed port of the post-calcination section 2 is higher than the feed port of the mol...

Embodiment 2

[0035] A method for producing rock wool from coal gangue, the specific steps are the same as in Example 1, the difference is that the formula of the raw materials has been adjusted: specifically, 50kg of coal gangue, 20kg of slag, 15kg of diatomite and 15kg of Kaolin; the same structure used in the melting tank kiln.

Embodiment 3

[0037] A method for producing rock wool from coal gangue, the specific steps are the same as in Example 1, the difference is that the formula of the raw materials has been adjusted: specifically, 72kg of coal gangue, 15kg of slag, 8kg of diatomaceous earth and 5kg of Kaolin; the same structure used in the melting tank kiln.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com