Method for treating tobacco stems through biological enzyme, prepared cut stems and prepared cigarettes

A technology of biological enzymes and tobacco stems, applied in the treatment of tobacco, tobacco, food science, etc., can solve the problems of poor sensory quality of cut stems, high breaking rate of cut stems, unstable quality, etc., so as to avoid excessive fermentation time. , low rate of broken silk, reduce wood gas and irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

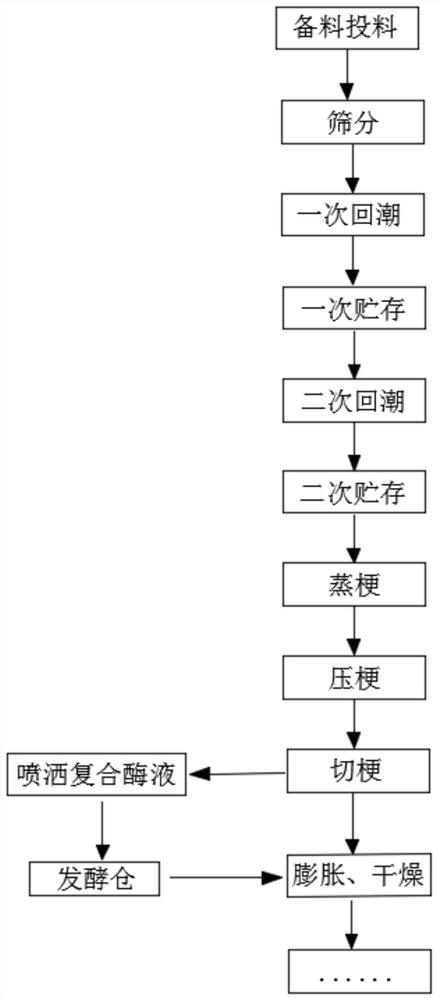

[0039] refer to figure 1 , a method for treating tobacco stems with biological enzymes, the specific steps are as follows:

[0040] (1) Prepare materials according to the process manufacturing capacity according to the formula requirements;

[0041](2) Screening and removing the broken stems in the tobacco stems, one moisture regain, one storage, secondary moisture regain, secondary storage and steaming the stems, so that the moisture content of the tobacco stems is 20%, and the temperature is 75° C.;

[0042] (3) pressing and cutting the tobacco stems obtained in the previous step, the thickness of the pressed stems is 1.5-2.5 mm, the width of the cut stems is 0.1-0.15 mm, and the length is 1-30 mm to obtain shredded stems;

[0043] (4) Step up the gained cut stem atomization and spray compound enzyme liquid, the consumption of described compound enzyme liquid is 2% of cut stem weight, the total activity of cellulase in every kilogram of compound enzyme is 100 million U, the...

Embodiment 2

[0048] A method for treating tobacco stems with biological enzymes, the specific steps are as follows:

[0049] (1) Prepare materials according to the process manufacturing capacity according to the formula requirements;

[0050] (2) Screening and removing the broken stems in the tobacco stems, one moisture regain, one storage, secondary moisture regain, secondary storage and steaming the stems, so that the moisture content of the tobacco stems is 15%, and the temperature is 85° C.;

[0051] (3) pressing and cutting the tobacco stems obtained in the previous step, the thickness of the pressed stems is 1.5-2.5 mm, the width of the cut stems is 0.1-0.15 mm, and the length is 1-30 mm to obtain shredded stems;

[0052] (4) Step up the gained cut stem atomization and spray compound enzyme liquid, the consumption of described compound enzyme liquid is 4% of cut stem weight, the total activity of cellulase in every kilogram of compound enzyme is 200 million U, the total activity of p...

Embodiment 3

[0057] A method for treating tobacco stems with biological enzymes, the specific steps are as follows:

[0058] (1) Prepare materials according to the process manufacturing capacity according to the formula requirements;

[0059] (2) Screening out the broken stems in the tobacco stems, one moisture regain, one storage, secondary moisture regain, secondary storage and steaming the stems, so that the moisture content of the tobacco stems is 25%, and the temperature is 65°C;

[0060] (3) pressing and cutting the tobacco stems obtained in the previous step, the thickness of the pressed stems is 1.5-2.5 mm, the width of the cut stems is 0.1-0.15 mm, and the length is 1-30 mm to obtain shredded stems;

[0061] (4) Step up the gained cut stem atomization and spray compound enzyme liquid, the consumption of described compound enzyme liquid is 1% of cut stem weight, the total activity of cellulase in every kilogram of compound enzyme is 100 million U, the total activity of protease Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com