Catalyst for synthesizing monoethylamine, preparation method and application

A technology of catalyst and ethylamine, which is applied in the field of industrial catalysts, can solve the problem of low selectivity of monoethylamine, and achieve the effects of industrial production, controllable process, and small amplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

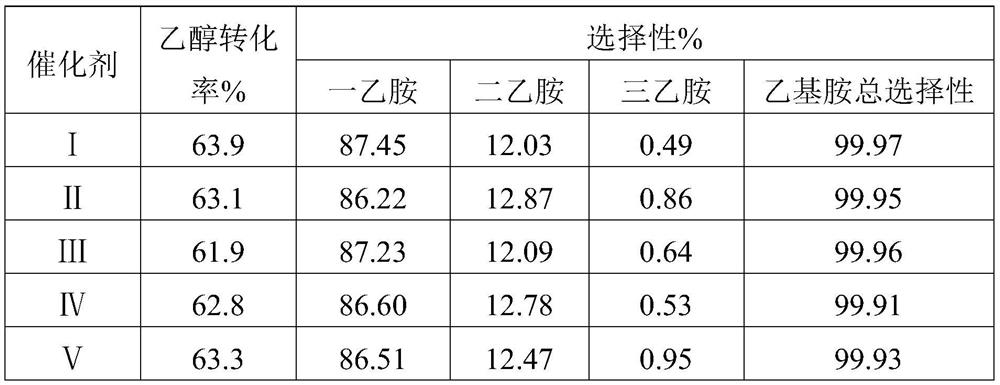

Examples

Embodiment 1

[0042] Add 50g of cobalt nitrate hexahydrate into 600mL of water and 600mL of ethanol for ultrasonic dissolution, and then use a compression atomizer to slowly spray the solution at 5KPa into a rotary evaporator equipped with 33.5g of gamma alumina balls with a diameter of Ф2mm. And rotate forward and reverse at a speed of 50r / min, switch between forward and reverse for 3s, then evaporate the solvent at 80°C, take it out and dry it at 60°C.

[0043] Using the same operation, spray ethanol and aqueous solution containing 0.35g of palladium acetate and ethanol and aqueous solution containing 0.05g of ammonium perrhenate in sequence, and dry the obtained solid at 350°C for 8 hours to obtain Co-Pd-Re / Al 2 o 3 Catalyst, denoted as Catalyst I.

[0044] X-ray fluorescence analysis was performed on the catalyst I obtained in this example. The catalyst contained 23.03% Co, 0.31% Pd and 0.08% Re, indicating that the catalyst was Co, Pd, and Re deposited on the surface of alumina.

Embodiment 2

[0046] Add 48g of cobalt nitrate hexahydrate into 600mL of water and 600mL of ethanol for ultrasonic dissolution, and then use a compression atomizer to slowly spray the solution at 5KPa into a rotary evaporator equipped with 30g of gamma alumina balls with a diameter of Ф3mm, and Rotate forward and reverse at a speed of 20r / min, switch between forward and reverse for 5s, then evaporate the solvent at 70°C, take it out and dry it at 60°C.

[0047] Using the same operation, spray ethanol and aqueous solution containing 1.95g of palladium nitrate dihydrate and ethanol and aqueous solution containing 0.03g of ammonium perrhenate in sequence, and dry the obtained solid at 350°C for 4 hours to obtain Co-Pd- Re / Al 2 o 3 Catalyst, denoted as Catalyst II.

[0048] According to X-ray fluorescence analysis, the catalyst is the same as in Example 1, and Co, Pd and Re are also deposited on the surface of alumina.

Embodiment 3

[0050] Add 55g of cobalt nitrate hexahydrate into 600mL of water and 600mL of ethanol for ultrasonic dissolution, and then use a compression atomizer to slowly spray the solution at 5KPa into a rotary evaporator equipped with 35g of gamma alumina balls with a diameter of Ф2mm, and Rotate forward and reverse at a speed of 50r / min, switch between forward and reverse for 3s, then evaporate the solvent at 80°C, take it out and dry it at 60°C.

[0051] Using the same operation, spray ethanol containing 1.17g of palladium chloride, aqueous solution, and ethanol and aqueous solution containing 0.26g of rhenium chloride in sequence. After drying, the obtained solid is roasted at 500°C for 4 hours to obtain Co-Pd-Re / al 2 o 3 Catalyst, denoted as catalyst III.

[0052] According to X-ray fluorescence analysis, the catalyst is the same as in Example 1, and Co, Pd and Re are also deposited on the surface of alumina.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com