a nb 2 c MXene material and its preparation method and application

A sodium-potassium alloy and battery technology, applied in chemical instruments and methods, structural parts, electrochemical generators, etc., can solve the problems that lithium batteries cannot be replaced and dendrites are easily generated, and achieve good cycle stability and dendrite growth Inhibition, the effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In one or some embodiments of the present disclosure, there is provided a kind of Nb 2 The preparation method of C MXene material, comprises the steps: prepare Nb 2 The AlC MAX phase is selectively etched with HF, and the Al layer is completely etched away.

[0025] Preferably, the preparation of Nb 2 The AlC MAX phase includes the following steps: mix Nb, Al and NbC in a certain proportion, ball mill, and heat for a period of time under an inert gas atmosphere to obtain Nb 2 AlC MAX phase.

[0026] Preferably, the Nb, Al and NbC mass ratio is 1-3:1-3:1-2;

[0027] Further preferably, the Nb, Al and NbC mass ratio is 2:1.2:1;

[0028] Preferably, the ball milling time is 20-50 minutes;

[0029] Further preferably, the ball milling time is 30 minutes;

[0030] Preferably, the inert gas is argon;

[0031] Preferably, the heating temperature is 1000-1500°C;

[0032] Further preferably, the heating temperature is 1400°C;

[0033] Preferably, the heating time is 1.5...

Embodiment 1

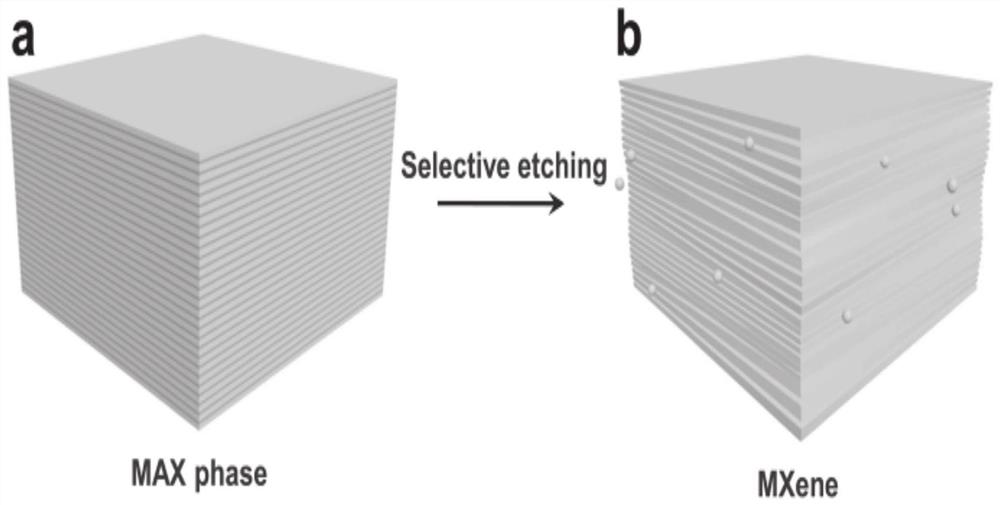

[0065] Such as figure 1 As shown, this embodiment provides a Nb 2 The preparation method of C MXene material, the gray sheet represents Nb 2 C, the black flakes represent the Al layer, and the small balls represent the sodium and potassium ions in the battery. The Nb 2 C MXene is produced by selective etching of MAX phase Nb 2 Al layer in AlC obtained.

[0066] It specifically includes the following steps: mix Nb, Al and NbC in a ratio of 2:1.2:1, ball mill for 30 minutes, and heat at 1400°C for two hours under an argon atmosphere to obtain Nb 2 AlC MAX phase.

[0067] Next, 2 g of Nb 2 AlC was crushed into smaller particles by ball milling for 30 minutes and selectively etched with 40% HF, and the mixture was stirred for 24 hours and centrifuged at a speed of 4000 rpm.

[0068] Collect the precipitate and wash repeatedly until the pH value of the supernatant is 6-7. Nb was obtained after drying 2 c.

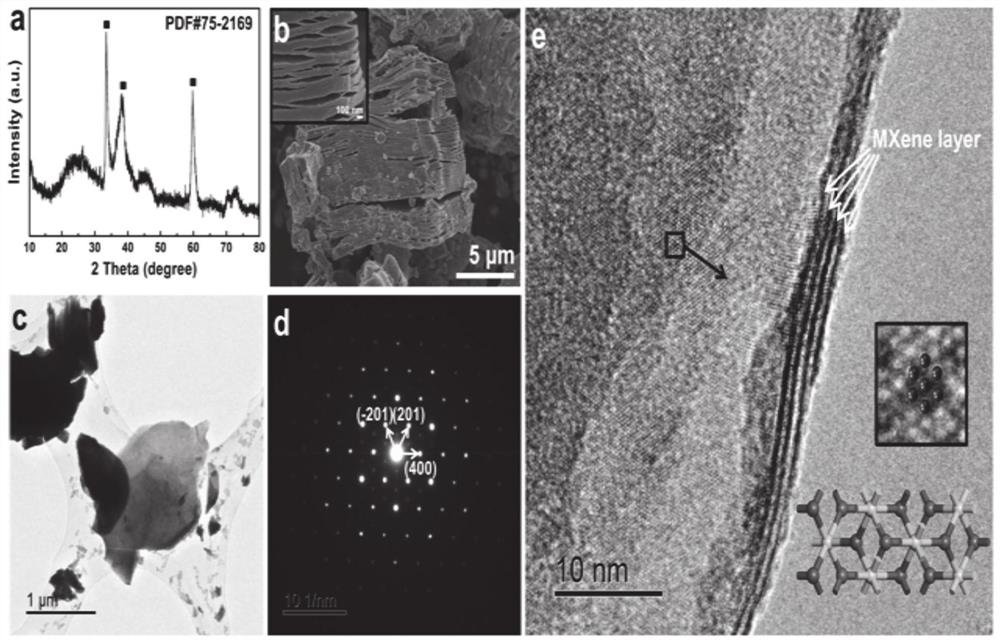

[0069] Characterize the material prepared in this embodiment, suc...

Embodiment 2

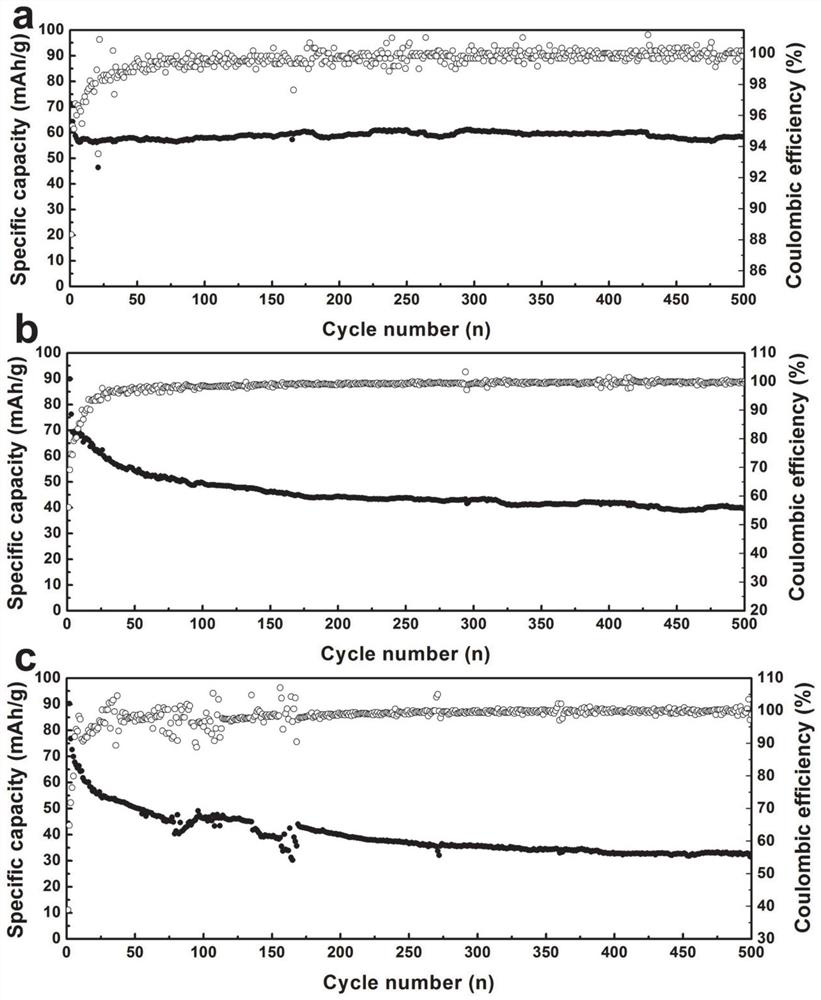

[0076] This embodiment provides a method for preparing a 2025 button battery, comprising the following steps:

[0077] Prepare the activation layer: mix the active material, polyvinylidene fluoride and acetylene black in a ratio of 8:1:1, add N-methylpyrrolidone and stir for 24 hours. The mixed slurry was then coated on a copper foil and vacuum dried at 60° C. for 10 hours.

[0078] Cut the dried pole pieces into small discs and pack them into batteries in the glove box. Glass fiber filter membrane as battery separator. Metal sodium, potassium and liquid sodium-potassium alloy were used as counter electrodes, respectively. All battery assembly is done in the glove box.

[0079] The preparation method of described liquid sodium potassium alloy comprises the steps:

[0080] By bringing solid sodium and potassium into physical contact and applying a certain external force, the two dissolve into each other to form a sodium-potassium alloy. After the alloy is heated to 420°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com