Composite fracturing prepad fluid and application thereof in hydraulic fracturing of tight reservoir

A composite fracturing and pre-fluid technology, applied in the drilling composition, production fluid, wellbore/well components, etc., can solve the problems of loss of oil and gas diversion channels, low matrix permeability, and high water injection cost. Achieve redistribution, promote percolation, and enhance spontaneous imbibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

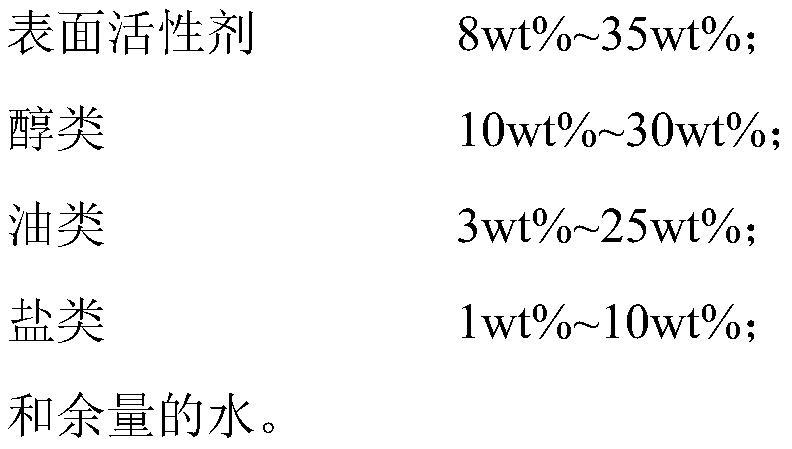

[0043] This embodiment provides a kind of composite fracturing prefluid, and this composite fracturing prefluid is obtained by fly ash (through 325 mesh sieves, that is, the particle size is greater than or equal to 325 mesh, and the density of the flyash is 1.5g / cm 3 , breakage rate under 28MPa closing pressure is 2.8%), microemulsion and drag reducer are prepared by adding water, wherein, in the composite fracturing prefluid, fly ash accounts for 0.1wt%, and microemulsion accounts for 0.1wt% , the drag reducer (conventional drag reducer in this field) accounts for 0.8wt%.

[0044]Wherein, in the microemulsion, based on 100g of the microemulsion, it includes: 15g of MOA-7, 12g of MOA-9, 1.5g of OP-10, 5g of sodium octyl succinate sulfonate, 30g of iso Propanol, 20g of cyclohexane, 5g of limonene, 5g of ammonium chloride and the remainder of water.

Embodiment 2

[0046] This embodiment provides a composite fracturing prefluid, which is obtained from quartz sand (through a 230 mesh sieve, that is, the particle size is greater than or equal to 230 mesh, and the density of the quartz sand is 2.7g / cm 3 , the breaking rate under 28MPa closing pressure is 8.5%), microemulsion and drag reducer are prepared by adding water, wherein, in the composite fracturing prefluid, quartz sand accounts for 0.1wt%, microemulsion accounts for 0.15wt%, The drag reducer (conventional drag reducer in this field) accounts for 0.6wt%.

[0047] Wherein, in the microemulsion, based on 100 g of the microemulsion, it includes: 10 g of sodium α-alkenyl sulfonate, 5 g of sodium dodecylbenzene sulfonate, 10 g of propylene glycol, 10 g of cyclohexane, 10g of sodium sulfate and the remainder of water.

Embodiment 3

[0049] This embodiment provides a composite fracturing prefluid, which is obtained by ceramsite (passing through a 200 mesh screen, that is, the particle size is greater than or equal to 200 mesh, and the density of the ceramsite is 2.9g / cm 3 , the breaking rate under 28MPa closing pressure is 3.5%), microemulsion and drag reducer are prepared by adding water, wherein, in the composite fracturing prefluid, quartz sand accounts for 0.2wt%, microemulsion accounts for 1.0wt%, The drag reducer (conventional drag reducer in this field) accounts for 0.8wt%.

[0050] Wherein, in the microemulsion, based on 100g of the microemulsion, it includes: 10g of dodecyltrimethylammonium bromide, 10g of tetradecyltrimethylammonium chloride, 10g of tetradecyl Trimethyl ammonium bromide, ethylene glycol of 5g, propylene glycol of 25g, pinene of 20g, limonene of 5g, potassium chloride of 5g and the water of surplus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com