Polymer-based waterproof coating and preparation method thereof

A waterproof coating, polymer technology, applied in the direction of coating, can solve the problems of poor storage stability, unstable coating system, easy to deteriorate, etc., to improve surface hardness and waterproof performance, improve internal cross-linking density, surface Density-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

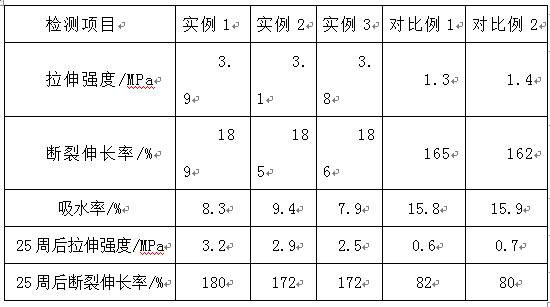

Examples

preparation example Construction

[0032] A preparation method of a polymer-based waterproof coating, the specific preparation steps comprising:

[0033] Phosphogypsum pretreatment:

[0034] In parts by weight, successively take 60-80 parts of phosphogypsum, 60-80 parts of absolute ethanol, 8-10 parts of concentrated sulfuric acid, and 10-20 parts of calcium chloride solution with a mass fraction of 1-10%. After mixing the phosphogypsum and the absolute ethanol ball mill, then adding the concentrated sulfuric acid, heating and stirring for reaction, then adding the calcium chloride solution, and adjusting the pH to alkaline, and reacting with hydrothermal stirring for 3-6 hours, Concentrate and dry to obtain pretreated phosphogypsum;

[0035] Enzymatic hydrolysis of chitosan:

[0036] Add chitosan enzyme with a chitosan solution mass of 0.01-0.03 to the chitosan solution with a mass fraction of 1-10%, stir the enzymolysis reaction for 3-5 hours, heat up to kill the enzyme, and cool to obtain chitosan enzymat...

Embodiment 1

[0044] Phosphogypsum pretreatment:

[0045] In parts by weight, successively take 60 parts of phosphogypsum, 60 parts of dehydrated ethanol, 8 parts of concentrated sulfuric acid, and 10 parts of calcium chloride solution with a mass fraction of 1%, and first ball mill the phosphogypsum and the dehydrated ethanol After mixing, add the concentrated sulfuric acid, heat and stir for reaction, then add the calcium chloride solution, adjust the pH to alkaline, react with hydrothermal stirring for 3 hours, concentrate and dry to obtain pretreated phosphogypsum;

[0046] Enzymatic hydrolysis of chitosan:

[0047] Adding chitosanase with a chitosan solution mass of 0.01 to a chitosan solution with a mass fraction of 1%, stirring the enzymolysis reaction for 3 hours, heating up to kill the enzyme, and cooling to obtain a chitosan enzymolysis solution;

[0048] Preparation of stabilizer:

[0049] In parts by weight, successively take 20 parts of the chitosan enzymolysis solution, 3 pa...

Embodiment 2

[0053] Phosphogypsum pretreatment:

[0054] In parts by weight, successively take 80 parts of phosphogypsum, 80 parts of dehydrated alcohol, 10 parts of concentrated sulfuric acid, and 20 parts of calcium chloride solution with a mass fraction of 10%, and first ball mill the phosphogypsum and the dehydrated ethanol After mixing, add the concentrated sulfuric acid, heat and stir for reaction, then add the calcium chloride solution, adjust the pH to alkaline, react with hydrothermal stirring for 6 hours, concentrate and dry to obtain pretreated phosphogypsum;

[0055] Enzymatic hydrolysis of chitosan:

[0056] To the chitosan solution with a mass fraction of 10%, add chitosanase with a chitosan solution quality of 0.03, stir the enzymolysis reaction for 5 hours, heat up to kill the enzyme, and cool to obtain chitosan enzymolysis solution;

[0057] Preparation of stabilizer:

[0058] In parts by weight, successively take 30 parts of the chitosan enzymolysis solution, 5 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com