High-performance high-capacity hydrogen storage alloy for fuel cell and preparation method of hydrogen storage alloy

A hydrogen storage alloy and fuel cell technology, which is applied in the field of magnesium-based hydrogen storage alloy and its preparation, can solve problems such as not being able to meet the needs of vehicles, and achieve the effects of improving kinetic performance and reducing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

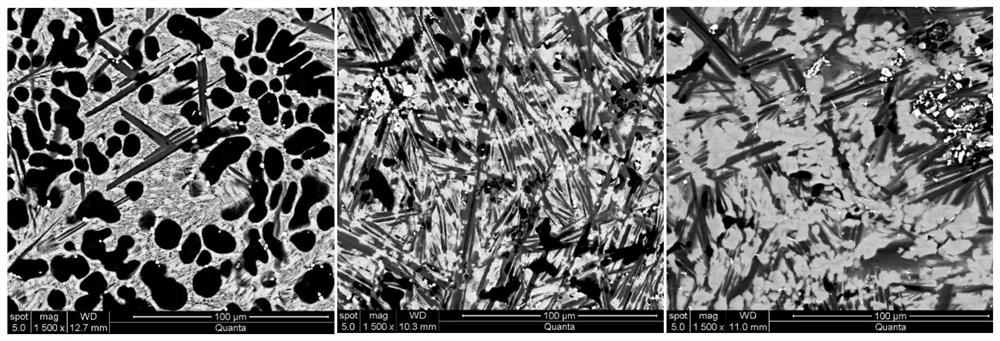

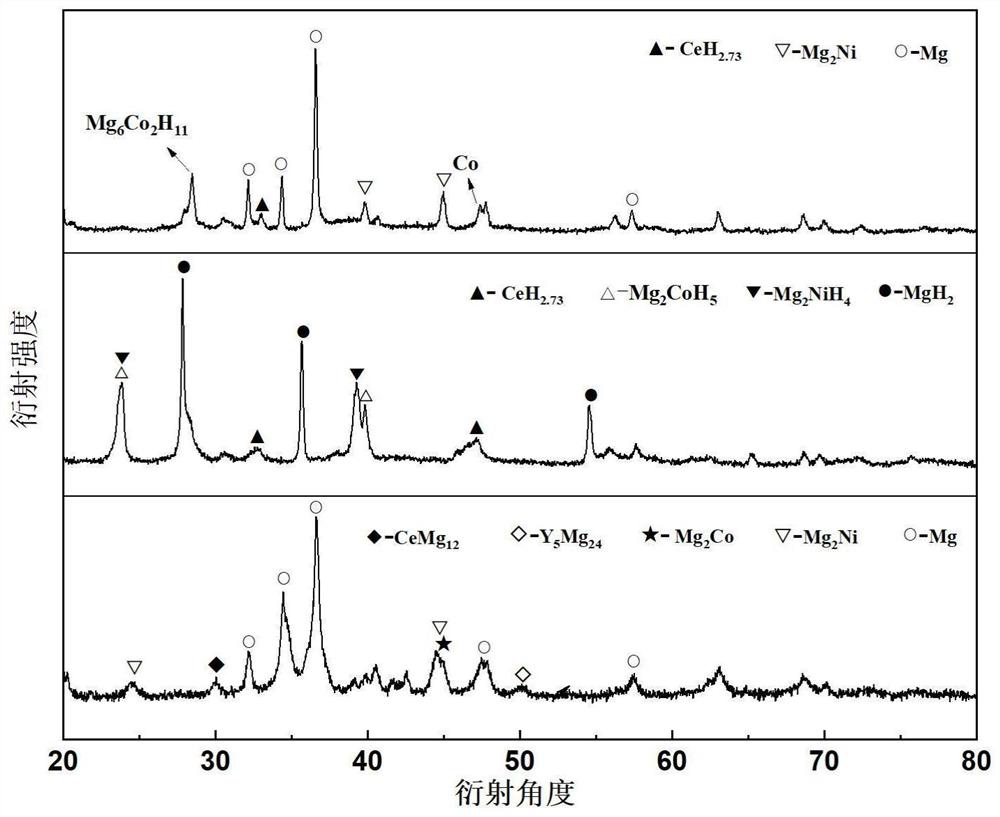

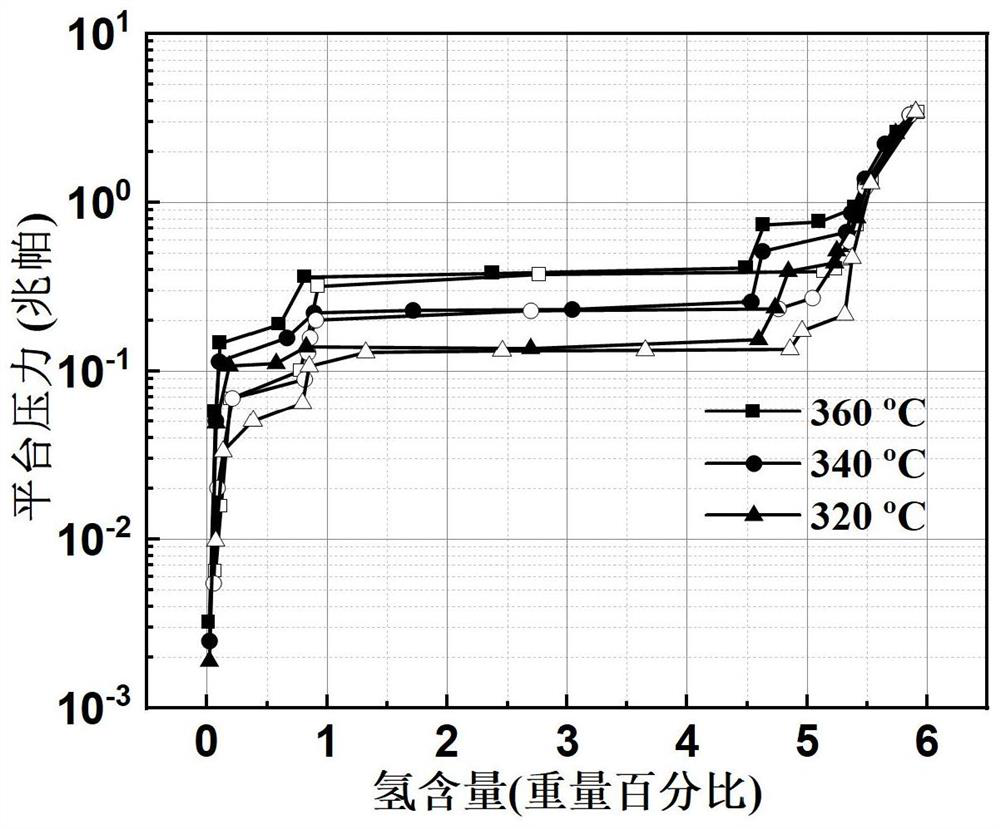

[0031] Example 1: Mg 90 (Ce,Y) 3 (Ni,Co) 7 (x=10, a=3, b=7)

Embodiment 2

[0032] Example 2: Mg 90 (Ce,Y) 5 (Ni,Co) 5 (x=10, a=5, b=5)

Embodiment 3

[0033] Example 3: Mg 80 (Ce,Y) 10 (Ni,Co) 10 (x=0, a=10, b=10)

[0034] Example 1

[0035] Select bulk metal cerium, metal yttrium, and metal nickel and cobalt with purity ≥ 99.5%. These metals have the chemical formula (Ce,Y) 3 (Ni,Co) 7278.3 grams of metal cerium, 176.6 grams of metal yttrium, 272 grams of metal nickel, and 273.1 grams of metal cobalt were weighed respectively. Put the weighed metal in the magnesia crucible of the intermediate frequency induction furnace, evacuate to a vacuum degree below 0.05Pa, and then pass in 0.06MPa helium as a protective gas. Adjust the heating power and control the temperature at 1800°C. After all the metals are melted, pour the melt into the mold after electromagnetic stirring for 5 minutes, and cool to room temperature to obtain the cast Ce-RE-Ni-Co master alloy.

[0036] Take 743.4 grams of metal magnesium, and prepare 256.6 grams of the Ce-RE-Ni-Co master alloy, place it in the magnesium oxide crucible of the intermediate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com