Hollow LDH/MnO2 nanocage composite material as well as preparation method and application thereof

A composite material, nano-cage technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low discharge capacity, inability to achieve high capacity of lithium-air batteries, easy stacking, etc. The effect of accelerating mass transfer process, excellent catalytic activity, and improving kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

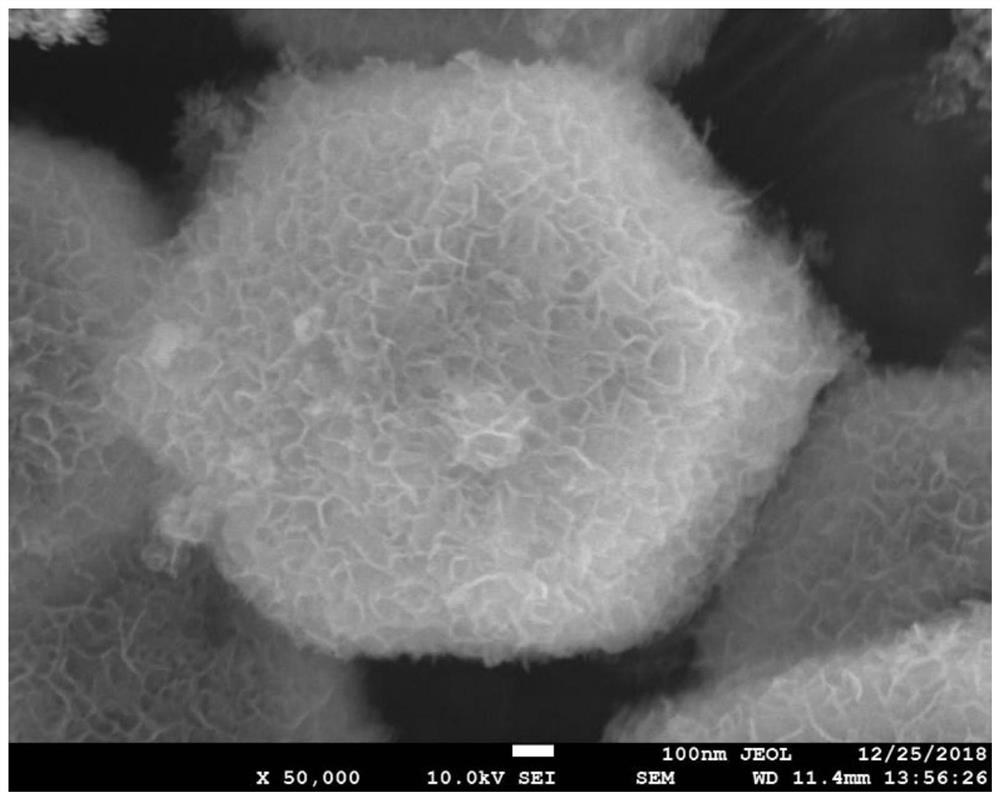

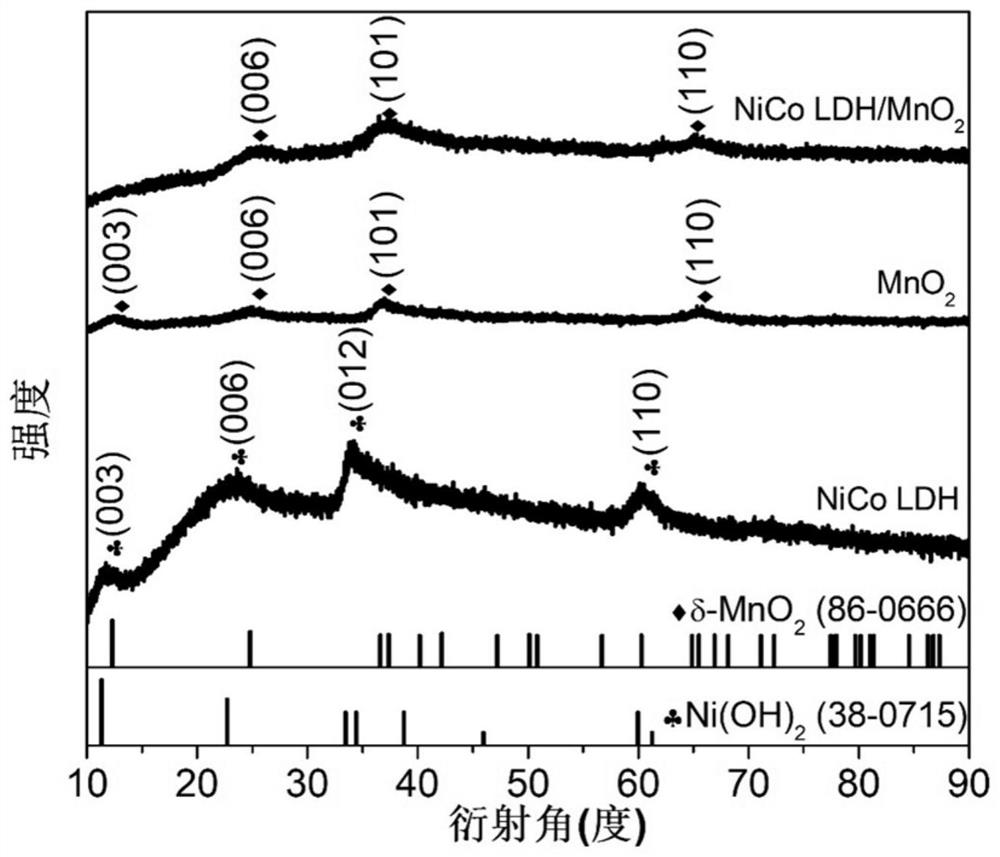

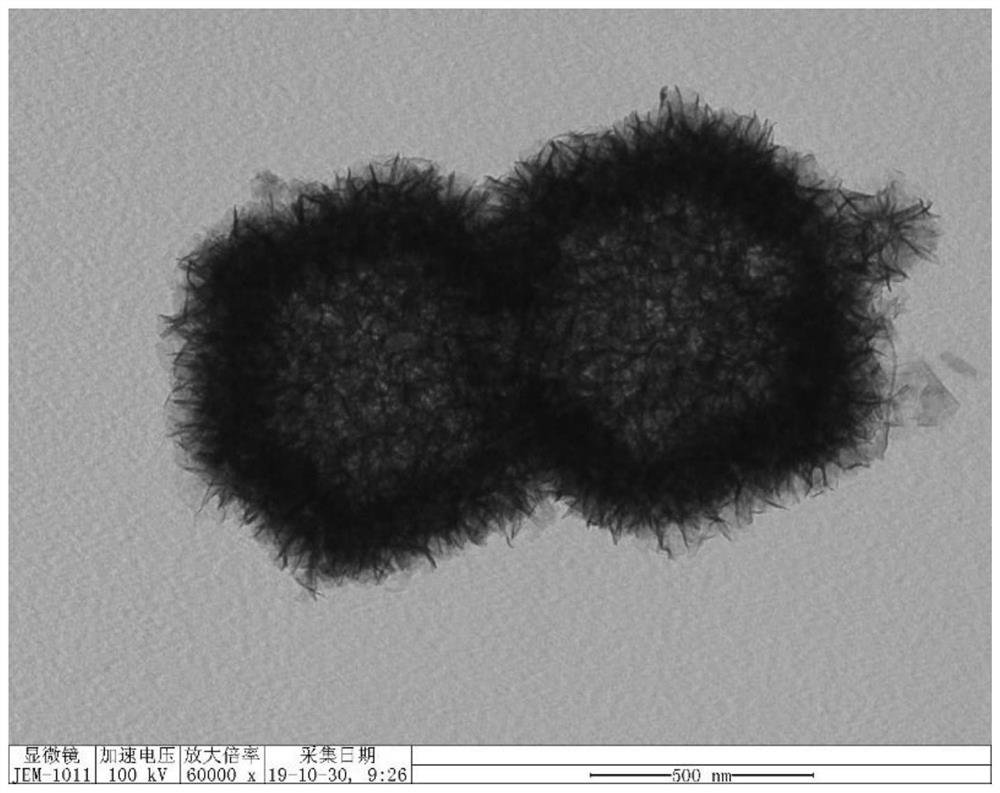

[0052] A Hollow NiCo LDH / MnO 2 The preparation method of nano cage composite material, comprises steps as follows:

[0053] (1) Add 0.728g of cobalt nitrate hexahydrate and 0.821g of 2-methylimidazole into 20mL of methanol respectively, and ultrasonically vibrate for 5 minutes to obtain a methanol solution of cobalt nitrate and a methanol solution of 2-methylimidazole, and 2-methylimidazole The methanol solution of cobalt nitrate was added to the methanol solution of cobalt nitrate and mixed evenly. The resulting mixed solution was aged at room temperature for 24 hours, and the precipitate was collected by centrifugation. The obtained precipitate was washed with methanol three times, and dried at 60°C for 12 hours to obtain ZIF-67.

[0054] (2) 0.1g ZIF-67 and 0.5g nickel nitrate are added in 20mL ethanol respectively, ultrasonic vibration 10min, obtain ZIF-67 dispersion liquid and nickel nitrate dispersion liquid, nickel nitrate dispersion liquid is added in ZIF-67 dispersion...

Embodiment 2

[0067] A Hollow CoCo LDH / MnO 2 The preparation method of nano cage composite material, comprises steps as follows:

[0068] (1) Described with embodiment 1 step (1).

[0069] (2) 0.1g ZIF-67 and 0.5g cobalt nitrate are added in 20mL methanol respectively, ultrasonic vibration 10min, obtain ZIF-67 dispersion liquid and cobalt nitrate dispersion liquid, cobalt nitrate dispersion liquid is added in ZIF-67 dispersion liquid, in The reaction was continuously stirred in a water bath at 60° C. for 1 h, and the precipitate was collected by centrifugation. The obtained precipitate was washed with ethanol three times, and dried at 60° C. for 12 h to obtain a CoCo LDH material.

[0070] (3) Add 70mg CoCo LDH material to 20mL 0.03mol / L KMnO 4 solution, stirred and mixed for 1 h, transferred the resulting mixture to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, and reacted hydrothermally at 160°C for 3 h; after the reaction was completed, centrifuged, and the centrifug...

Embodiment 3

[0074] A Hollow CuCo LDH / MnO 2 The preparation method of nano cage composite material, comprises steps as follows:

[0075] (1) Described with embodiment 1 step (1).

[0076] (2) Add 0.1g ZIF-67 and 0.5g cupric chloride into 20mL ethanol respectively, and oscillate ultrasonically for 10min to obtain ZIF-67 dispersion and cupric chloride dispersion, and add cupric chloride dispersion to ZIF-67 dispersion In 60 °C water bath, the reaction was continuously stirred for 1 h, the precipitate was collected by centrifugation, the obtained precipitate was washed with ethanol three times, and dried at 60 °C for 12 h to obtain the CuCo LDH material.

[0077] (3) Add 70mg CuCo LDH material to 20mL 0.03mol / L KMnO 4 solution, stirred and mixed for 1 h, transferred the resulting mixture to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, and reacted hydrothermally at 160°C for 3 h; after the reaction was completed, centrifuged, and the centrifuged precipitate was washed 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com