Method for recycling positive electrode material of waste ternary lithium ion battery

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of recycling and reuse of positive electrode materials of waste ternary lithium ion batteries, can solve the problems of destroying the crystal structure of positive electrode materials, unfavorable to green environmental protection, harmful toxicity, etc., and achieves simple process and large-scale realization. applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

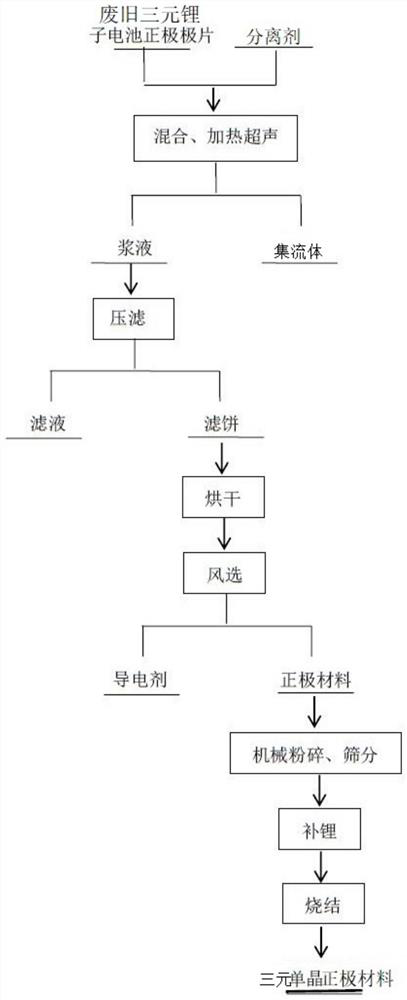

[0046] In this embodiment, a method for recycling the positive electrode material of a waste ternary lithium-ion battery, the specific steps are as follows:

[0047] Mix the NCM811 waste ternary lithium ion positive pole piece with the thiourea solution at a mass ratio of 1:5, completely soak the positive pole piece in the thiourea solution, heat to 60°C, and sonicate for 8 hours. Then, remove the aluminum foil;

[0048] The slurry after removing the aluminum foil was subjected to pressure filtration, wherein the pressure of the filter press was 0.12 MPa, to obtain filtrate and filter cake respectively. Then, the filter cake is vacuum-dried in an oven at 200°C, and the dried filter cake is separated from the dried filter cake by winnowing the ternary positive electrode material and the conductive agent;

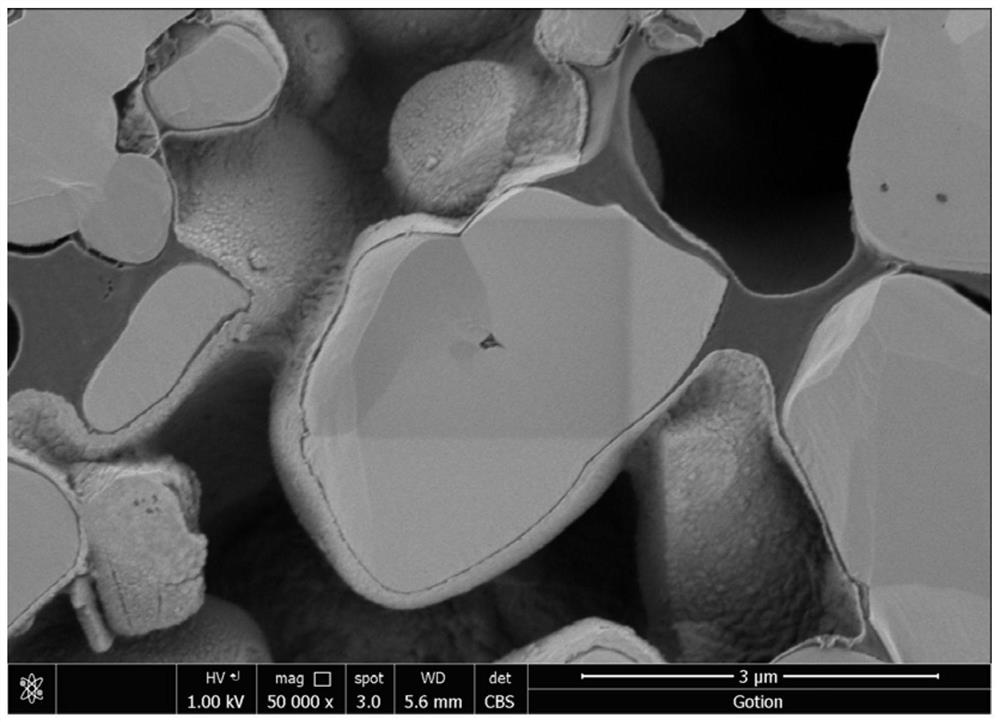

[0049] The separated ternary cathode material is mechanically crushed and sieved to obtain a particle size D 50 Particles of 3.5 μm;

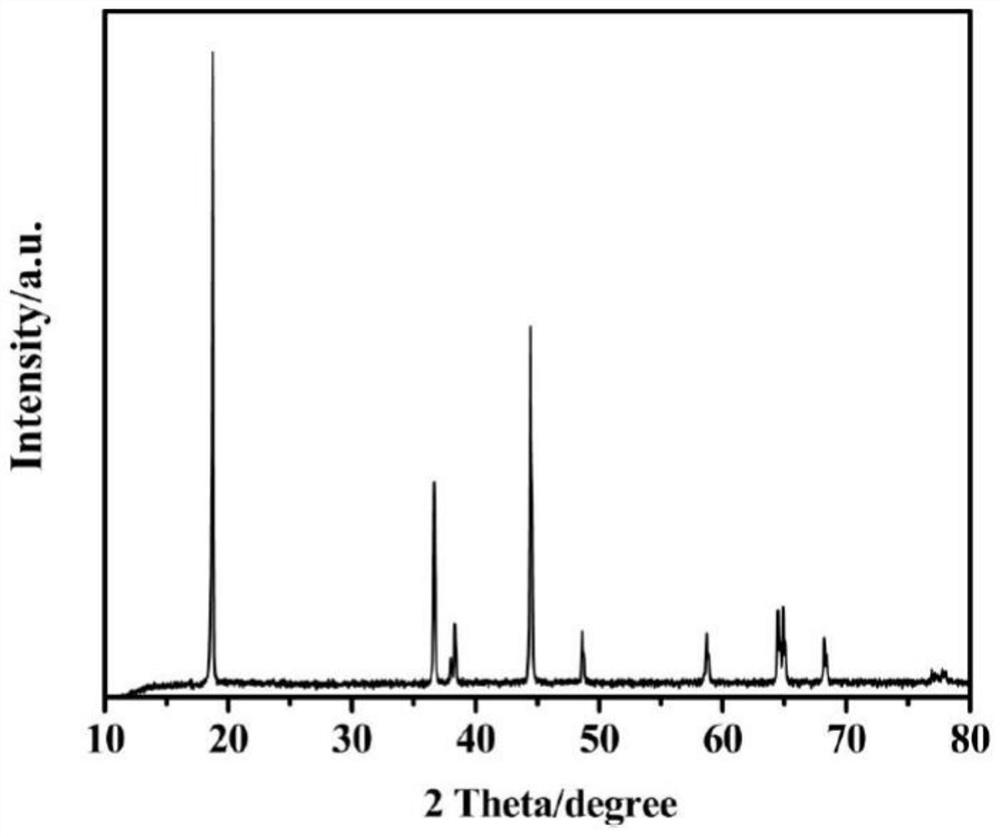

[0050] The sieved ternary positive e...

Embodiment 2

[0057] In Example 1, the NCM811 waste ternary lithium ion positive pole piece was replaced with NCM523 waste ternary lithium ion positive pole piece, and the steps of peeling off the aluminum foil, press filtration, winnowing and mechanical crushing were the same as in Example 1. Then, the particle size after mechanical crushing meets the requirements (D 50 =2~5μm) of the ternary positive electrode material for ICP element analysis to obtain the ratio of lithium to the total mass of transition metal elements, and then supplement Li according to the molar ratio of lithium to transition metal elements Li / M=1:1.13 2 CO 3 Finally, place it in a muffle furnace, in an air atmosphere, raise the temperature from room temperature to 500°C, keep it warm for 5 hours, then raise the temperature to 970°C, and keep it warm for 15 hours. Finally, it was naturally cooled to room temperature to obtain NCM523 ternary single crystal cathode material. A button cell was assembled in the same man...

Embodiment 3

[0059] In this example, the waste NCM622 ternary lithium ion positive pole pieces were soaked in dichloromethane solution, heated and ultrasonicated, followed by press filtration, winnowing, mechanical pulverization and ICP elemental analysis. The steps were the same as in Example 1. Then, according to the ratio of the total molar ratio of lithium to transition metal elements of 1:1.09, Li 2 CO 3 Finally, put it in the muffle furnace, keep the box pressure at 60MPa, in the air atmosphere, first raise the room temperature to 500°C, keep it for 5h, then raise it to 950°C, and keep it for 15h. Finally, it was naturally cooled to room temperature to obtain NCM622 ternary single crystal cathode material. A button cell was assembled in the same manner as in Example 1, and the electrochemical performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com