Preparation method of lignin nano microspheres

A technology of nano-microspheres and lignin, which is applied in the field of preparation of lignin nano-microspheres, can solve the problems of cumbersome pretreatment, maintaining stability, and being difficult for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Get 100ml of self-made black liquor sample, filter through filter paper and remove solid impurities therein, add 900ml of distilled water to dilute to obtain diluent;

[0027] (2) At room temperature, add 2mol / L sulfuric acid to the diluent under agitation, adjust the pH value of the diluent to be 6 and precipitate out at the same time, continue to stir for 30min at room temperature, at a stirring speed of 500rpm, centrifuge (3000r / min) after stirring , 15min) to obtain the first-level precipitate and the first-level supernatant; continue to add 2mol / L sulfuric acid in the first-level supernatant under stirring conditions, adjust the pH value to be 4 and separate out the precipitate simultaneously, and obtain the second-level precipitate and the Secondary supernatant; continue to add 2mol / L sulfuric acid to the secondary supernatant under stirring conditions, adjust the liquid pH value to 2 and precipitate precipitates at the same time, and obtain third-grade precipi...

Embodiment 2

[0032] Compared with Example 1, the difference of Example 2 is that the addition of ultrapure water in the step (4) is 65% of the suspension quality, and it is the same as the operation of Example 1.

[0033]The prepared lignin nano-microspheres were detected, and the dispersion performance of the lignin nano-microspheres was improved.

Embodiment 3

[0035] Compared with Example 1, the difference of Example 2 is that the addition of ultrapure water in step (4) is 70% of the suspension quality, which is the same as in Example 1 with operation.

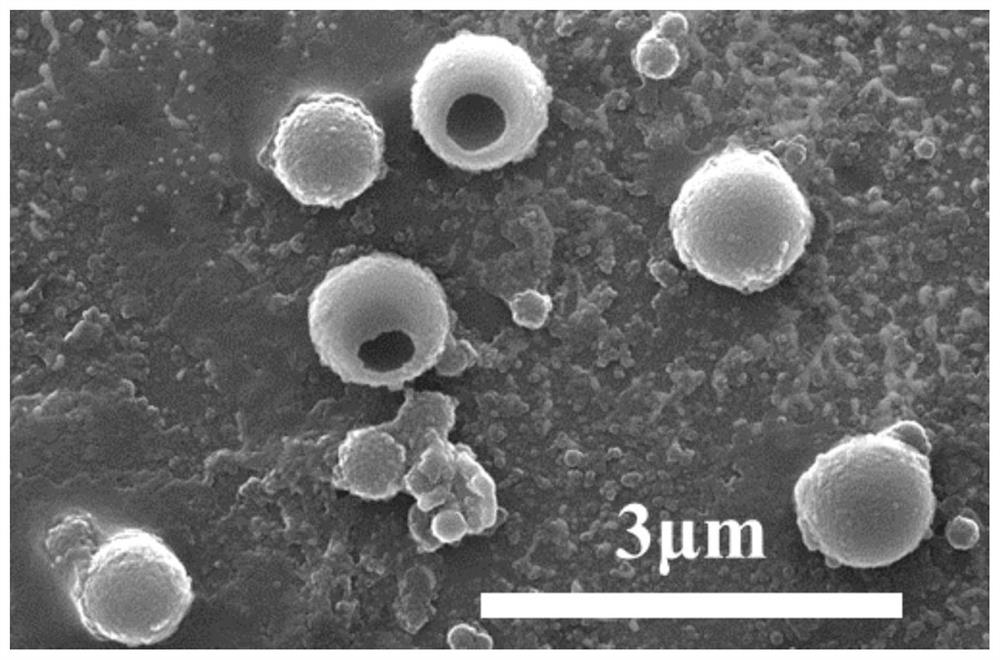

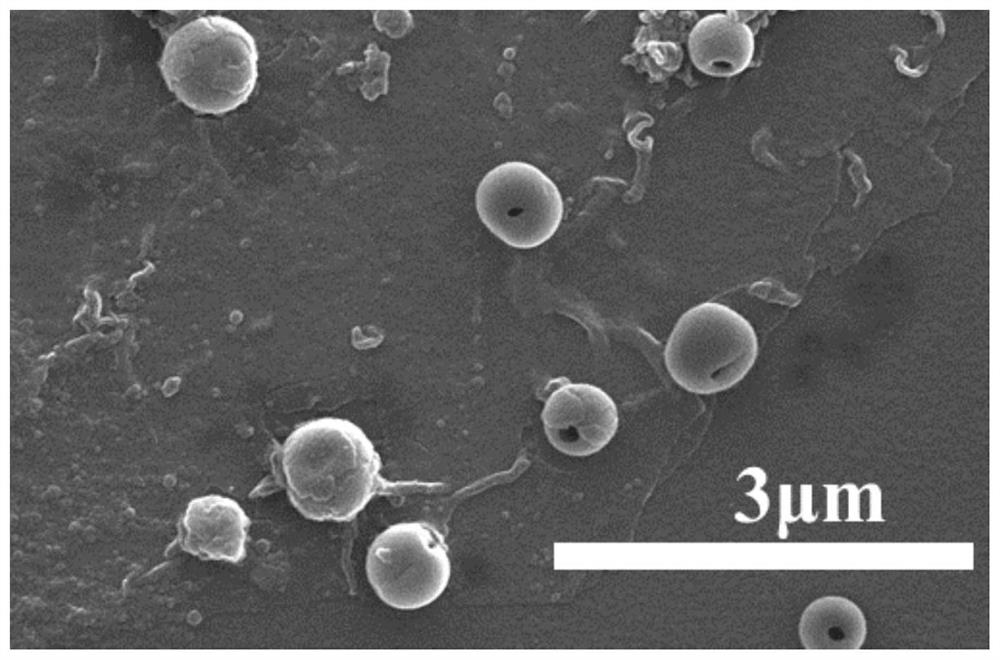

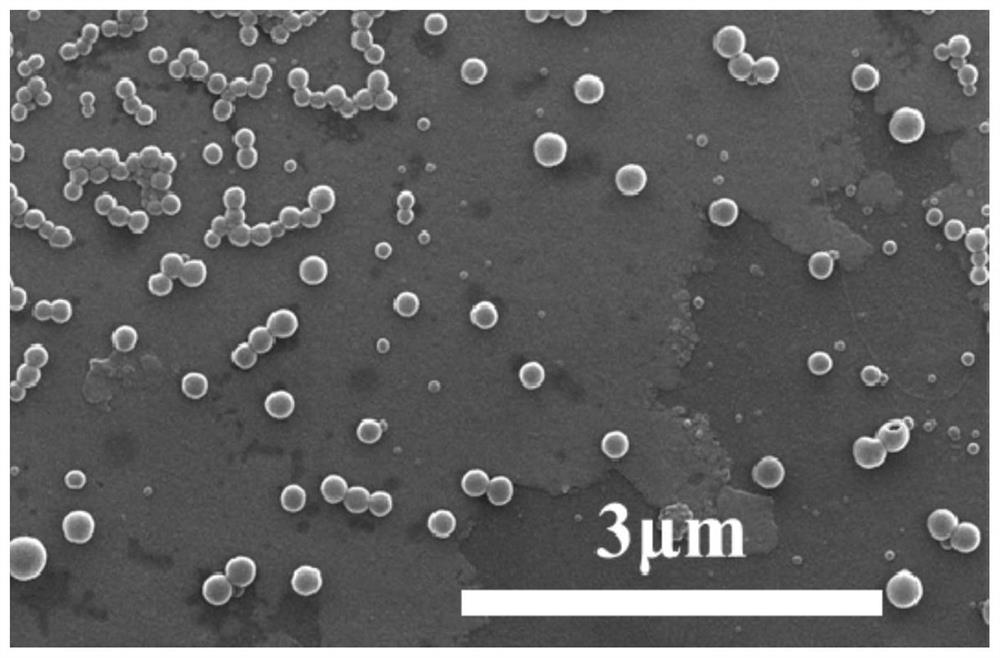

[0036] Carry out SEM detection to the lignin nano-microsphere that embodiment 3 makes, the result is as follows Figure 1-3 as shown, Figure 1-Figure 3 The lignin nanospheres corresponding to raw material lignin KL1, KL2, KL3 respectively, from Figure 1-3 It can be seen that the lignin nanospheres prepared in this example have high sphericity and good dispersion performance; and with the reduction of the phenolic hydroxyl content of the raw material lignin, the particle size and hollowness of the prepared nanospheres show a gradual decrease. small trend.

[0037] In order to evaluate the stability of lignin nanospheres, the changes of particle size and Zeta potential of lignin nanospheres with time and pH value were detected. After being placed in solutions with different pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com