Preparation method of silicon dioxide aerogel thermal insulation material by normal-pressure microwave plasma method

A microwave plasma, silica technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of increasing the production cost of silica aerogel, expensive equipment, and overall structure collapse, and achieves The effect of good thermal insulation and cooling effect, simplified production process and reduced production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

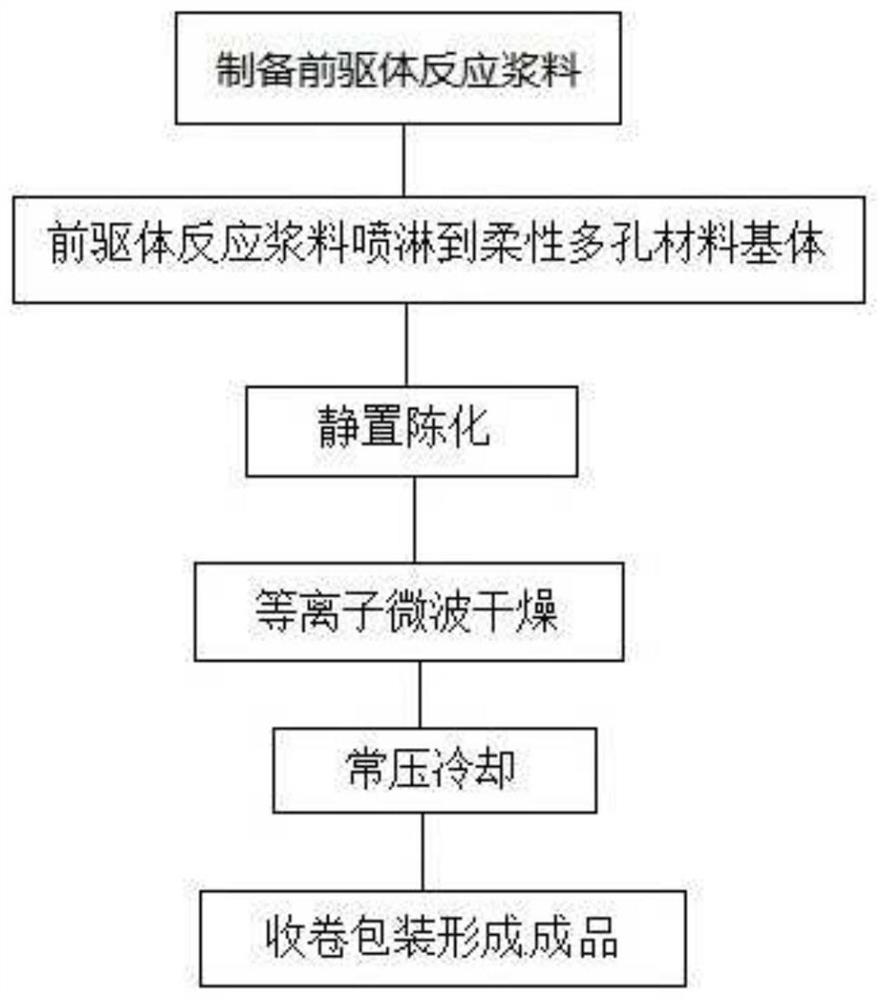

[0039] A method for preparing a silica airgel thermal insulation material by an atmospheric pressure microwave plasma method, comprising the following steps:

[0040] The first step is to prepare the precursor reaction slurry:

[0041] In the second step, spraying the precursor reaction slurry described in the first step onto the surface of the flexible porous material matrix;

[0042] The third step is to statically age the flexible porous material matrix obtained in the second step;

[0043] The fourth step is to perform plasma microwave drying on the flexible porous material matrix after standing and aging in the third step;

[0044] The fifth step is to cool the flexible porous material matrix after the plasma microwave drying treatment in the fourth step to room temperature under normal pressure;

[0045] In the sixth step, the single-layer airgel flexible porous material matrix prepared after cooling at normal pressure in the fifth step is prepared into a single-layer ...

Embodiment 1

[0071] A method for preparing silica airgel thermal insulation material by atmospheric pressure microwave plasma method, the specific steps of the preparation method are as follows:

[0072] (a) Preparation of precursor reaction slurry

[0073] Thoroughly mix silicon source, metal alkoxide, alcohols, hydrophilic modifier and opacifier, the molar ratio is 1:0.01:0.005:0.01:0.001, add dedistilled water to the mixed solution to dilute, at 1000r / min Stir uniformly for 1 min under the conditions to prepare a reaction slurry with a mass fraction of 2.5%.

[0074] (b) Atmospheric pressure wetting of precursor slurry on flexible porous material

[0075] The flexible porous material substrate is positioned on the conveyor belt with a mechanical transfer device such as a pressure roller, and then the uniformly mixed precursor reaction slurry is transported to the spray roller coating nozzle by a liquid transfer device, and the precursor is sprayed on both sides by double-sided spraying...

Embodiment 2

[0085] A method for preparing silica airgel thermal insulation material by atmospheric pressure microwave plasma method, the specific steps of the preparation method are as follows:

[0086] (a) Preparation of precursor reaction slurry

[0087] Thoroughly mix silicon source, metal alkoxide, alcohols, hydrophilic modifier and opacifier, the molar ratio is 1:0.02:0.05:0.25:0.01, add dedistilled water to the mixed solution for dilution, at 10000r / min Stir uniformly for 10 min under the conditions to prepare a reaction slurry with a mass fraction of 10%.

[0088] (b) Atmospheric pressure wetting of precursor slurry on flexible porous material

[0089] The flexible porous material substrate is positioned on the conveyor belt with a mechanical transfer device such as a pressure roller, and then the uniformly mixed precursor reaction slurry is transported to the spray roller coating nozzle by a liquid transfer device, and the precursor is sprayed on both sides by double-sided sprayi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Loose packing density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com