Rice bran protein porous material and application thereof

A technology of rice bran protein and porous materials, applied in the field of rice bran protein porous materials, can solve the problems of organic solvent residual hazards, long reaction time, low gel performance, etc., and achieve the effects of improving nutrition, easy preparation, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

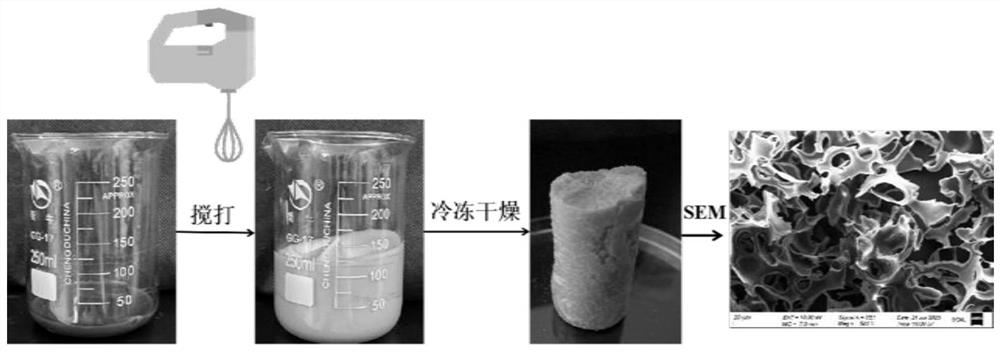

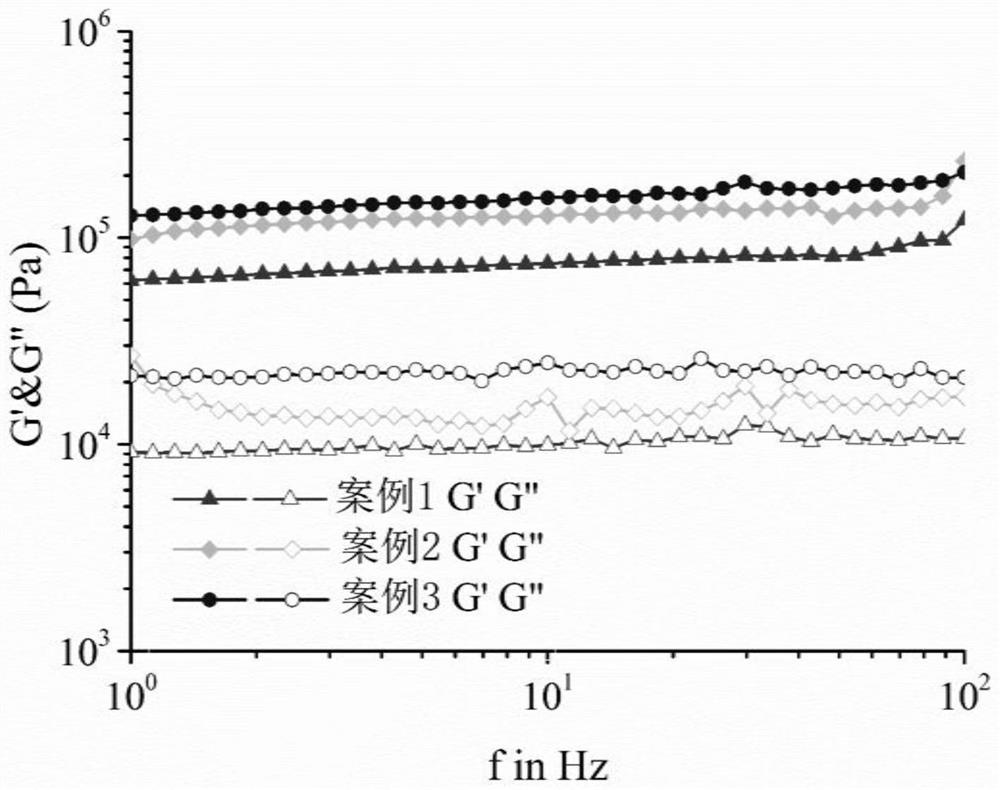

[0031] Such as figure 1 , accurately weigh 1.25g of rice bran protein and place it in 25g of pH 11 phosphate buffer solution to prepare a 5% rice bran protein solution; use a beater (Germany Braun HM5100) to whip the rice bran protein solution for 5min with a power of 700W to prepare rice bran protein protein foam; the rice bran protein porous material can be obtained by vacuum freeze-drying the rice bran protein foam.

Embodiment 2

[0033] Accurately weigh 0.5 g of rice bran protein and place it in 25 g of pH 7 phosphate buffer solution to prepare a 2% rice bran protein solution; beat the rice bran protein solution for 10 minutes with a beater (Germany Braun HM5100) with a power of 700W to prepare a rice bran protein foam The rice bran protein foam is subjected to vacuum freeze-drying to obtain the rice bran protein porous material.

Embodiment 3

[0035] Accurately weigh 1.25g of rice bran protein and place it in 25g of pH 9 phosphate buffer solution to prepare a 5% rice bran protein solution; place the rice bran protein solution in a water bath and boil it for 10 minutes to completely expand the disulfide bonds of the rice bran protein and let it stand Cooling; beat the rice bran protein solution with a beater (Braun HM5100, Germany) for 5 minutes with a power of 700W to prepare a rice bran protein foam; vacuum freeze-dry the rice bran protein foam to obtain a rice bran protein porous material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com