PC/PMMA alloy as well as preparation method and application thereof

A technology of alloy and copolymer, which is applied in the field of PC/PMMA alloy and its preparation, can solve the problems of complex process and pearlescent, and achieve the effects of high light transmittance, low cost and small creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] In one embodiment, the preparation method of the polymethyl methacrylate copolymer comprises the following steps:

[0072] The main monomer, comonomer, solvent and initiator are mixed and reacted.

[0073] Preferably, the solvent is water, THF, DMF; and / or, the initiator is selected from azobisisobutyronitrile (AIBN) or dibenzoyl peroxide; and / or, the reaction temperature is 60-100℃. Preferably, the initiator is AIBN, and the reaction temperature is 70-90°C.

[0074] Preferably, the preparation method of the polymethyl methacrylate copolymer comprises the following steps:

[0075] The main monomers are mixed in proportion, recorded as 100 parts (weight parts), 0.1-0.2 parts of initiator are added, and 8-12 times the volume of water is added, and mixed under mechanical stirring, and the stirring speed is 500r / min, The reaction was carried out at 80°C for 4 hours. After the reaction, spherical particles were obtained, which were vacuum-dried at 70° C. for 4 hours and ...

Embodiment 1

[0098] This embodiment provides a PC / PMMA alloy and a preparation method thereof.

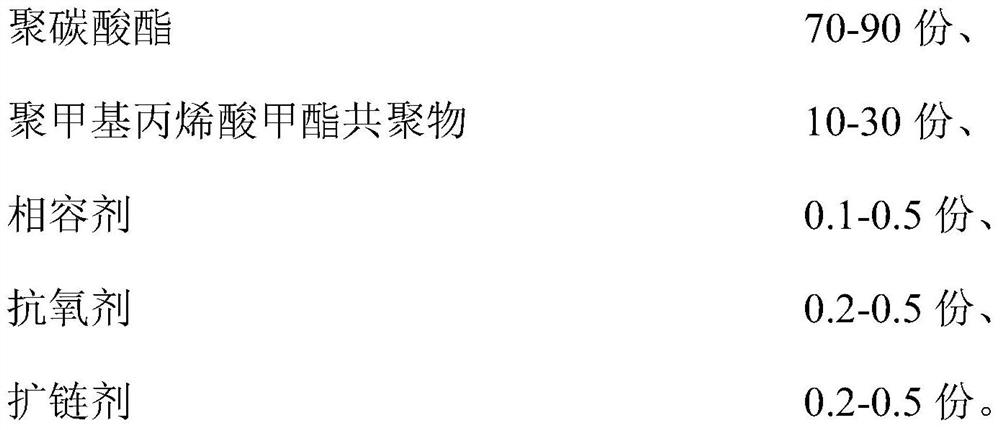

[0099] (1) PC / PMMA alloy is prepared from the raw material of following mass fraction in the present embodiment:

[0100]

[0101] The polymethyl methacrylate copolymer in this embodiment is prepared by free-radical copolymerization of methyl methacrylate and phenyl methacrylate in a molar ratio of 65:35, and the molecular weight is about 20,000 g / mol; PC is Bisphenol A type PC, the molecular weight is about 30000g / mol.

[0102] (2) preparation method is as follows:

[0103] S1 Preparation of polymethyl methacrylate copolymer: Mix the two monomers according to the molar ratio of 65:35, record it as 100 parts (weight parts), then add 0.2 parts of initiator and 10 times the volume of water, mechanically The mixture was mixed under stirring, the stirring speed was 500 r / min, and the reaction was carried out at 80° C. for 4 hours. After the reaction, spherical particles were obtained, which w...

Embodiment 2

[0106] This embodiment provides a PC / PMMA alloy and a preparation method thereof.

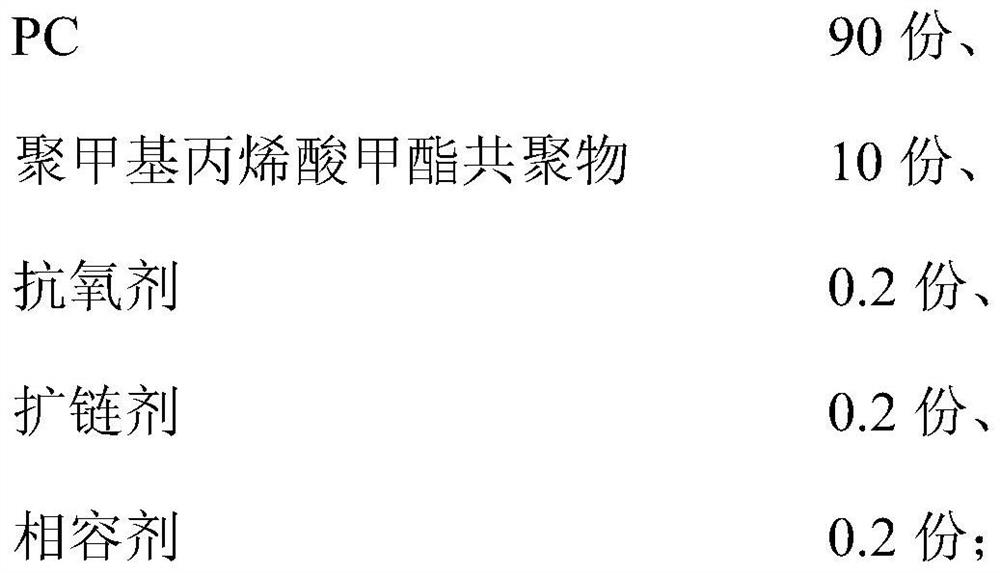

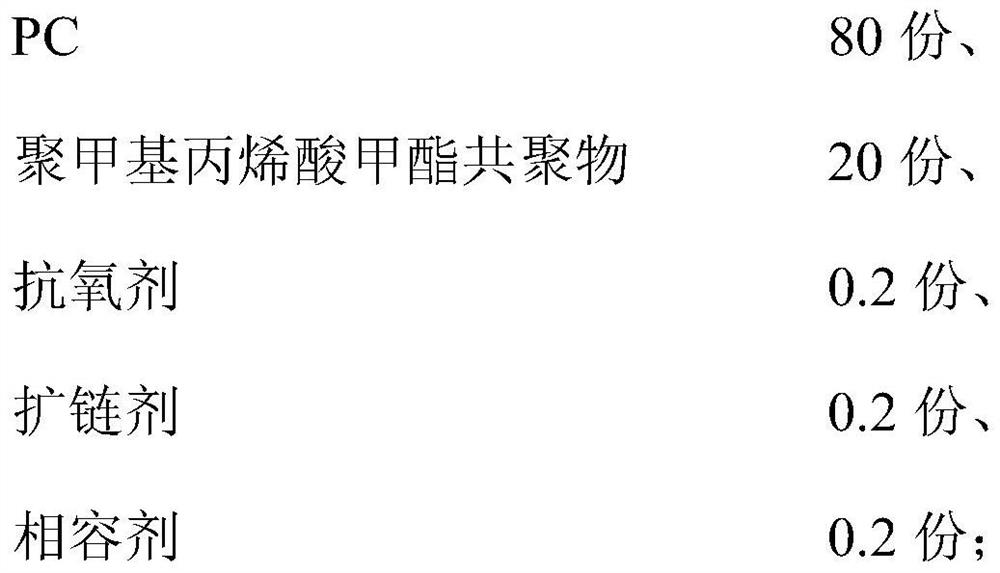

[0107](1) PC / PMMA alloy is prepared from the raw materials of following mass fractions in the present embodiment:

[0108]

[0109] The polymethyl methacrylate copolymer in this example is prepared by free radical copolymerization of methyl methacrylate and phenyl methacrylate in a molar ratio of 65:35, with a molecular weight of about 20,000 g / mol; PC is Bisphenol A type PC, the molecular weight is about 30000g / mol.

[0110] (2) The preparation method is as follows:

[0111] S1 prepares polymethyl methacrylate copolymer: same as embodiment 1.

[0112] S2 prepares PC / PMMA alloy: the above S1 polymethyl methacrylate copolymer and PC, compatibilizer, antioxidant, chain extender are fully mixed and then extruded by 35 co-rotating twin-screw extruders, extrusion temperature : 240°C-260°C, PC / PMMA alloy 2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com