Carbon nano organic temperature-resistant wave-absorbing coating, preparation method and coating method

A technology of wave-absorbing coatings and wave-absorbing coatings, which is applied to radiation-absorbing coatings, coatings, and devices for coating liquids on surfaces, and can solve problems such as insufficient wave-absorbing performance and insufficient temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

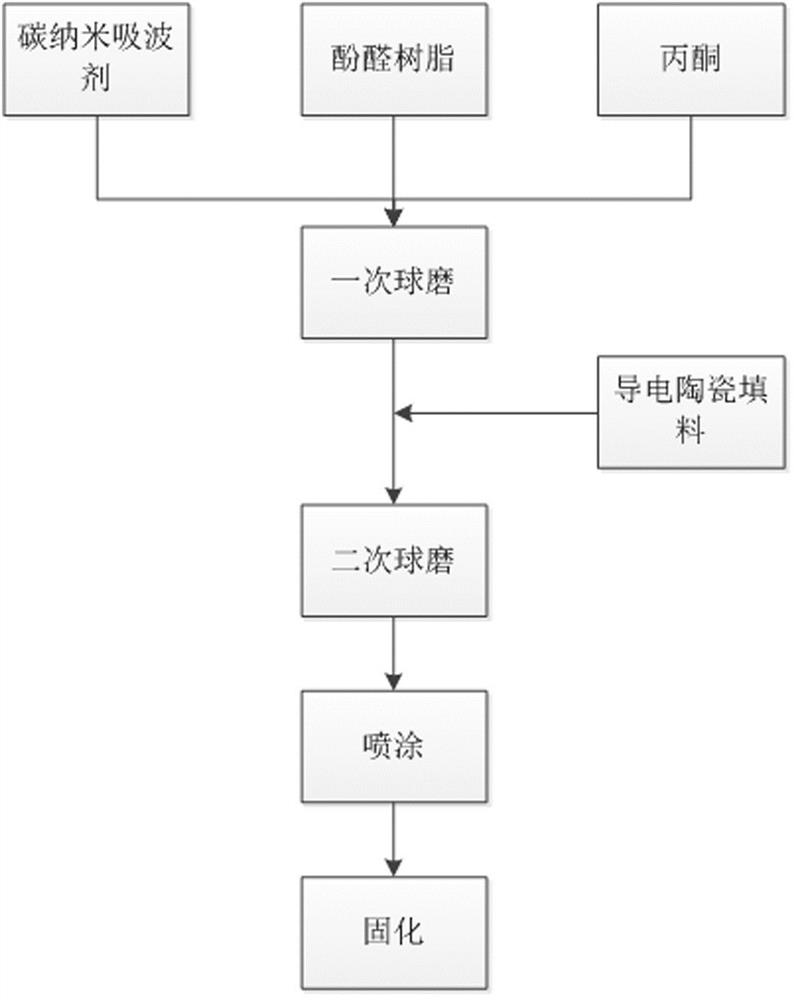

[0035] A preparation method of a carbon nanometer organic heat-resistant wave-absorbing coating, comprising the following steps:

[0036] S1, carbon nanomaterials are placed in a beaker, add phenolic resin and solvent and mix well;

[0037] S2. Transfer the mixed system to a ball milling tank for the first ball milling; the time for one ball milling is 2 to 6 hours;

[0038] S3. After the primary ball milling is completed, the conductive ceramic filler is added to the above ball milling system for secondary ball milling to prepare a carbon nanometer temperature-resistant wave-absorbing coating. The time for secondary ball milling is 0.5-1 hour.

[0039] A method for coating a carbon nanometer organic heat-resistant wave-absorbing coating, comprising the following steps:

[0040] S1. Apply the carbon nanometer temperature-resistant wave-absorbing coating to the substrate after surface treatment by spraying process, and control the surface square resistance and wave-absorbing ...

Embodiment 1

[0050] 1) Weigh 4.7 parts of graphene, 37.3 parts of phenolic resin and 46.8 parts of ethanol and mix well;

[0051] 2) Transfer the mixed system to a ball mill tank, conduct a ball mill, and set the ball mill time to 3h;

[0052] 3) After the first ball milling is completed, weigh 11.2 parts of conductive potassium titanate, add it to the above ball milling system for a second ball milling for 0.5h, and prepare the carbon nano heat-resistant wave-absorbing coating;

[0053] 4) Take a 300mm × 300mm × 4.5mm glass fiber reinforced epoxy resin substrate, wash the substrate with ethanol and deionized water in sequence and dry it, and spray a carbon nano heat-resistant wave-absorbing coating with a thickness of 30 μm on the surface of the substrate;

[0054] 5) Place the coated glass fiber reinforced epoxy resin substrate in a drying oven, and set the heating program: 80°C for 30 minutes, 100°C for 20 minutes, 120°C for 30 minutes, 165°C for 150 minutes; curing heating rate 2°C / m...

Embodiment 2

[0057] 1) Weigh 4.7 parts of multi-walled carbon nanotubes, 37.3 parts of phenolic resin and 46.8 parts of ethanol and mix them evenly;

[0058] 2) Transfer the mixed system to a ball mill tank, conduct a ball mill, and set the ball mill time to 3h;

[0059] 3) After the first ball milling is completed, weigh 11.2 parts of conductive potassium titanate, add it to the above ball milling system for a second ball milling for 0.5h, and prepare the carbon nano heat-resistant wave-absorbing coating;

[0060] 4) Take a 300mm × 300mm × 4.5mm glass fiber reinforced epoxy resin substrate, wash the substrate with ethanol and deionized water in sequence and dry it, and spray a carbon nano heat-resistant wave-absorbing coating with a thickness of 30 μm on the surface of the substrate;

[0061] 5) Place the coated glass fiber reinforced epoxy resin substrate in a drying oven, and set the heating program: 80°C for 30 minutes, 100°C for 20 minutes, 120°C for 30 minutes, 165°C for 150 minutes;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com