High-strength elastic foaming material and preparation process thereof

An elastic foaming, high-strength technology, applied in the preparation of carboxylate, the preparation of ammonia-carboxylic acid reaction, the preparation of organic compounds, etc. Performance reduction and other problems, to achieve the effect of increased toughness, high strength, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

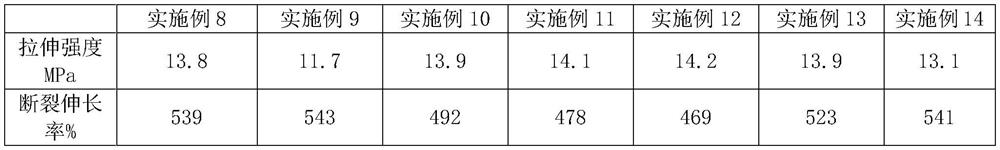

Examples

Embodiment 1

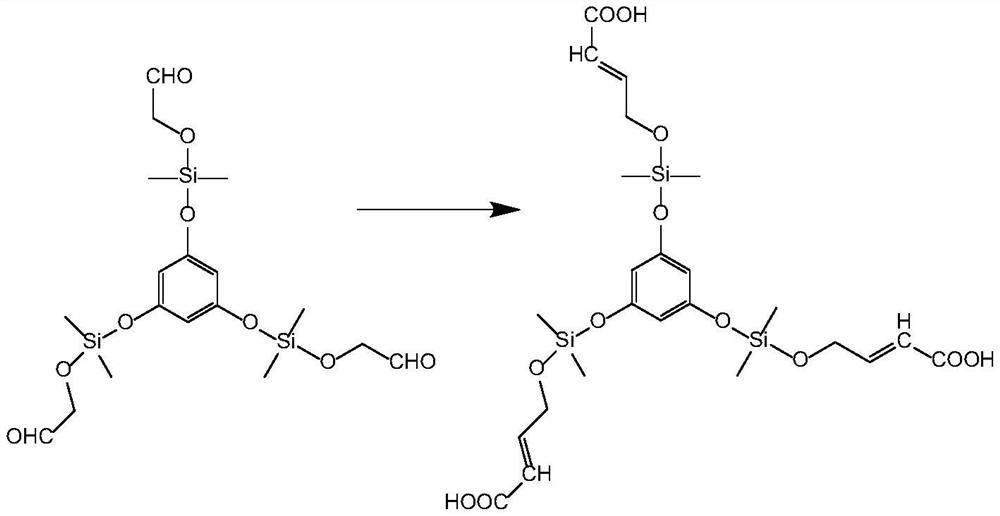

[0028] The preparation method of branched unsaturated silyl nitrile monomer is as follows:

[0029] Step 1: A condenser is installed on the reactor, and at the same time the condenser is connected to the by-product HCl absorption device, 1mol phloroglucinol and 1kg ether are added to the reactor at the same time, stirred and dissolved, and then controlled at 10°C to the reactor Add 3 mol dimethyldichlorosilane dropwise, control the dropwise addition within 2 hours, then stir the reaction for 8 hours, then add 3.3 mol ethylene glycol dropwise therein, control the dropwise addition within 1 hour, then raise the temperature to 95°C and reflux for 12 hours, reduce Obtain product A after pressure distillation removes excess reactant and solvent; Carry out infrared analysis to product A, in 3420cm -1 and 1063cm -1 Alcohol hydroxyl infrared absorption peak appeared at 1100cm -1 The infrared absorption peak of the silicon-oxygen bond appears at the place;

[0030] Step 2: Add 260g ...

Embodiment 2

[0035] The preparation method of the branched unsaturated silyl nitrile monomer is the same as that of Example 1, and the phloroglucinol used in step 1 of Example 1 is replaced by glycerin.

Embodiment 3

[0037] The preparation method of the unsaturated siliconitrile monomer is the same as in Example 1, and the phloroglucinol used in step 1 of Example 1 is replaced by hydroquinone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com