Self-healing gel solid electrolyte as well as preparation method and application thereof

A solid-state electrolyte and self-healing technology, which is applied in the direction of electrolyte immobilization/gelation, secondary battery manufacturing, and final product manufacturing, can solve problems such as safety accidents, breakage, and damage, and achieve improved ionic conductivity and high Room temperature ionic conductivity and effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

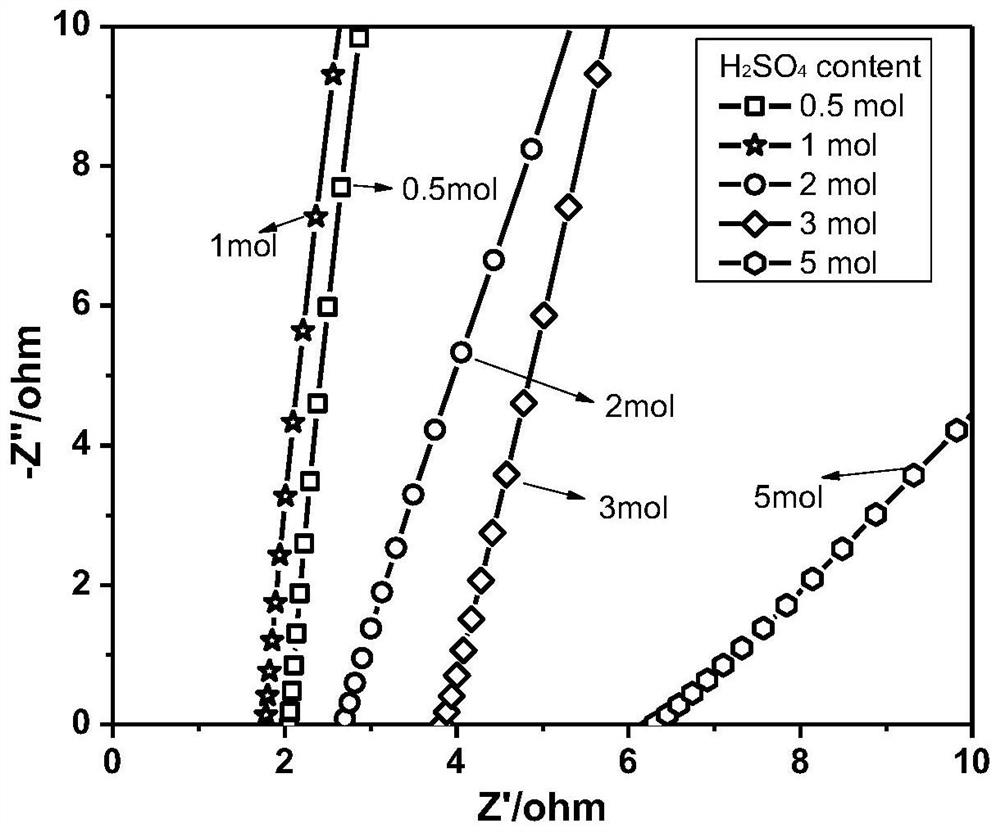

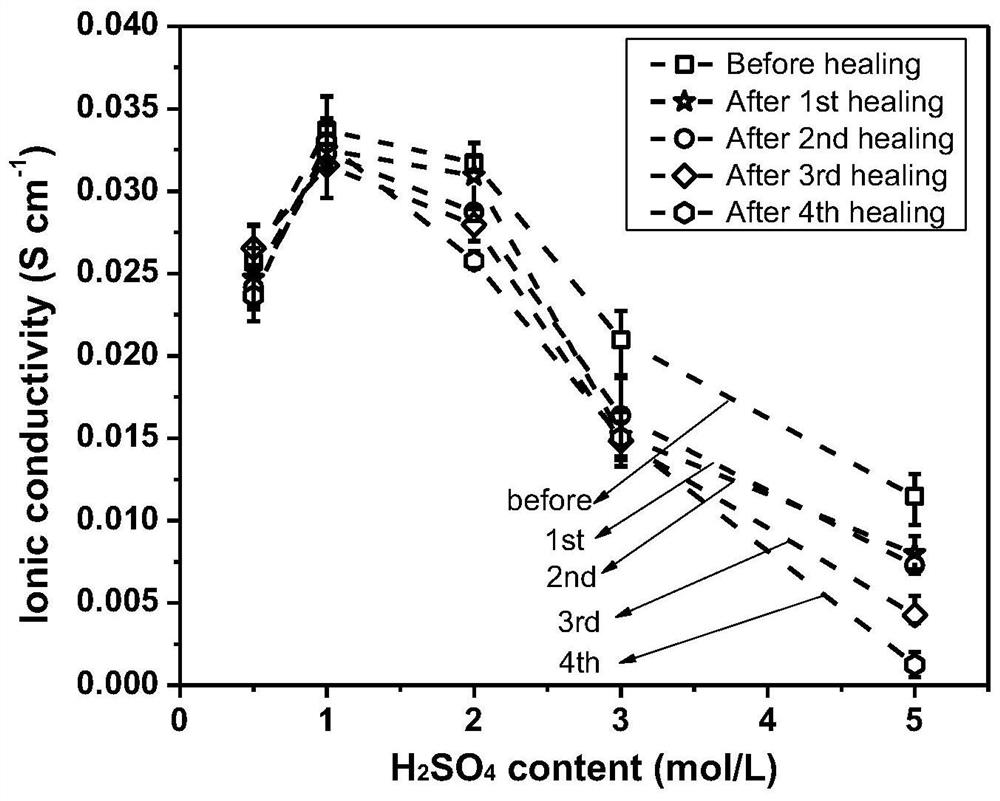

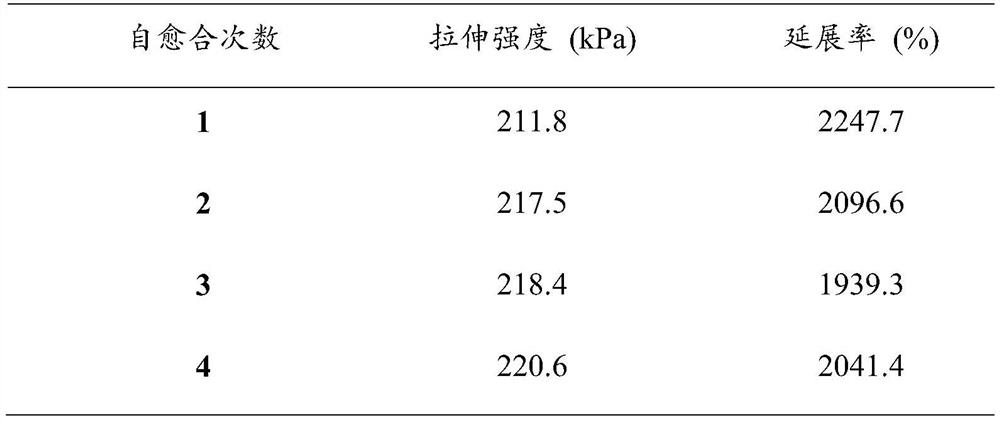

Embodiment 1

[0037]This embodiment is a preparation method of self-healing gel solid electrolyte, including the following steps:

[0038](1) Measure 50ml deionized water, 10g acrylic acid, 0.704g stearyl methacrylate, 0.139g Fe(NO3)3·6H2O, 1.52g cetyltrimethylammonium bromide and ammonium bromide were mixed with magnetic stirring for 2h.

[0039](2) The mixture prepared in step 1) is bubbled with nitrogen for 10 minutes.

[0040](3) Add 0.037g of potassium persulfate initiator to the mixed solution prepared in step 2), and pour it into a petri dish with magnetic stirring for 30 minutes. Place it in a blast drying oven at 60°C for 2h. Take out the solid electrolyte after polymerization from the petri dish, soak it in 0.5mol / L H2SO4A self-healing gel solid electrolyte is obtained in the solution.

Embodiment 2

[0042]This embodiment is a preparation method of self-healing gel solid electrolyte, including the following steps:

[0043] (1) Measure 50ml deionized water, 10g acrylic acid, 0.704g stearyl methacrylate, 0.139g Fe(NO3)3·6H2O, 1.52g cetyltrimethylammonium bromide and ammonium bromide were mixed with magnetic stirring for 2h.

[0044](2) The mixture prepared in step 1) was bubbled with nitrogen for 10 minutes.

[0045](3) Add 0.037g of potassium persulfate initiator to the mixture prepared in step 2), and pour it into a petri dish with magnetic stirring for 30 minutes. Place in a blast drying oven at 60°C for 2h. Take out the solid electrolyte after polymerization from the petri dish, soak it in 1mol / L H2SO4A self-healing gel solid electrolyte is obtained in the solution.

Embodiment 3

[0047]This embodiment is a preparation method of self-healing gel solid electrolyte, including the following steps:

[0048](1) Measure 50ml deionized water, 10g acrylic acid, 0.704g stearyl methacrylate, 0.139g Fe(NO3)3·6H2O, 1.52g cetyltrimethylammonium bromide and ammonium bromide are mixed with magnetic stirring for 2h.

[0049](2) The mixture prepared in step 1) is bubbled with nitrogen for 10 minutes.

[0050](3) Add 0.037g of potassium persulfate initiator to the mixed solution prepared in step 2), and pour it into a petri dish with magnetic stirring for 30 minutes. Place in a blast drying oven at 60°C for 2h. Take out the solid electrolyte after polymerization from the petri dish, soak it in 2mol / L H2SO4A self-healing gel solid electrolyte is obtained in the solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com