Lithium-sulfur secondary battery as well as preparation method and application thereof

A technology of lithium-sulfur secondary battery and conductive agent, which is applied in the direction of lithium storage battery, electrolyte storage battery manufacturing, battery electrode, etc. The effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Preparation of bentonite / sulfur composite cathode material

[0045]Add 5g of bentonite to 50mL of 1M LiCl aqueous solution, stir at 60°C for 2h, filter, and wash the filter cake repeatedly with deionized water until no chloride ions exist in the washing liquid.

[0046] Add the washed filter cake to 500mL deionized water, stir for 1h to obtain a suspension with a mass fraction of 1wt%; heat the above suspension to 60°C, 3+ The ratio of / g bentonite, slowly add the polymerized hydroxyaluminum ion intercalation agent, stir while adding, continue to add the concentration of 1wt% cetyltrimethylammonium bromide aqueous solution, stirring while adding, after the cetyltrimethylammonium bromide aqueous solution is added, continue to stir at 60°C for 6h, then stand at room temperature for aging After 24 hours, filter, wash the filter cake repeatedly with deionized water until there is no chloride ion in the washing liquid, and dry at 105° C. to obtain bentonite modified by inte...

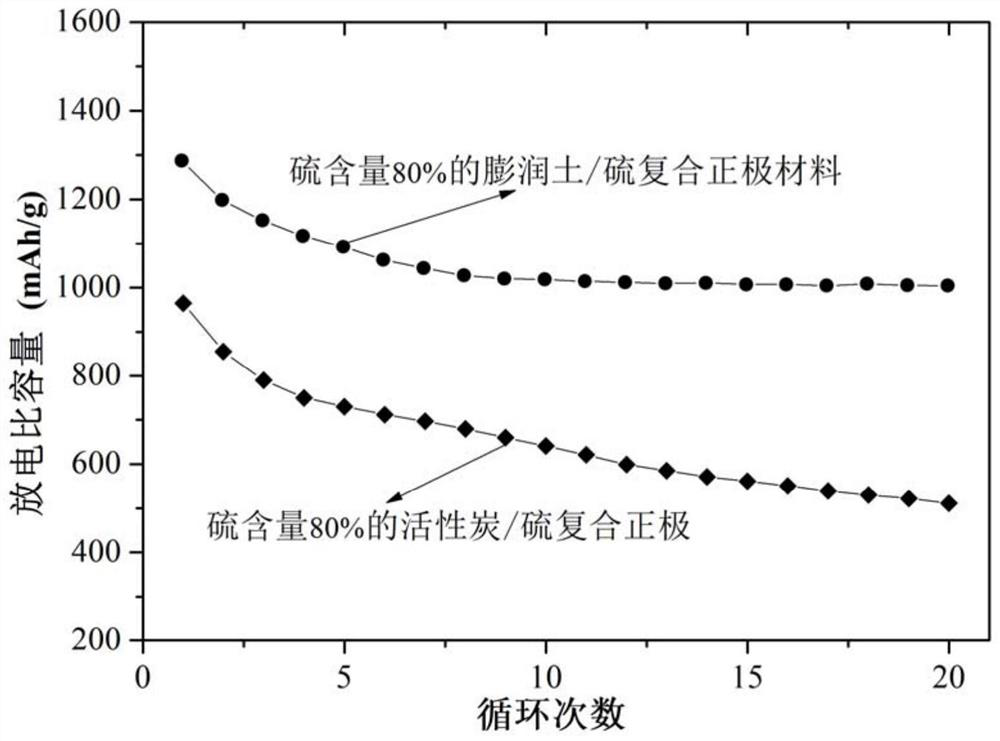

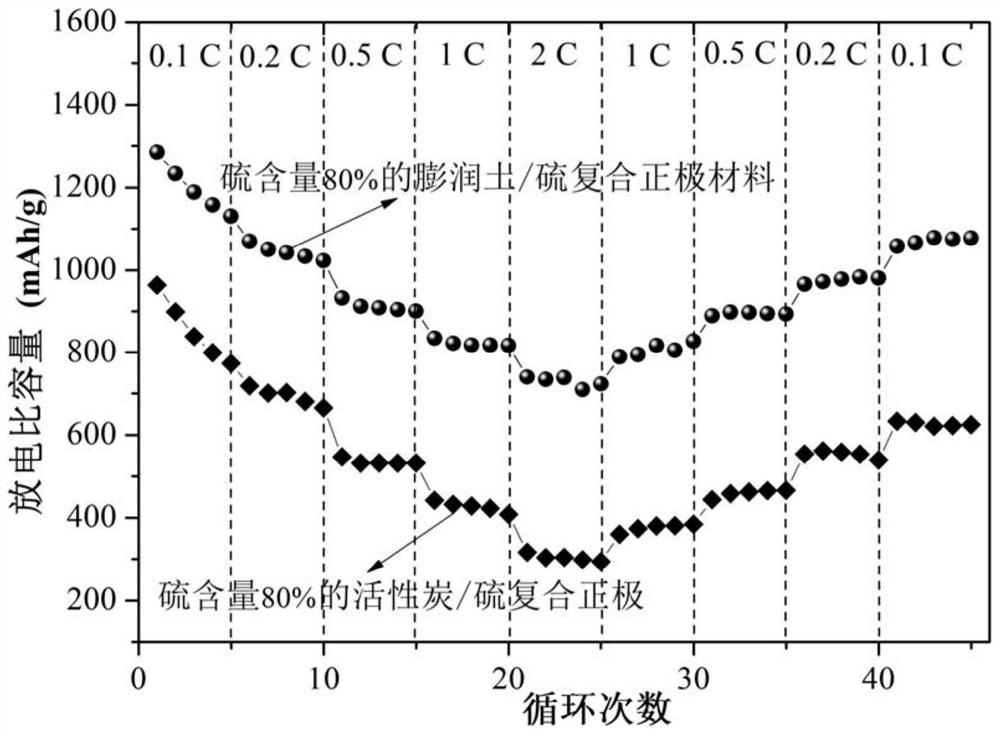

Embodiment 1

[0051] Take the bentonite / sulfur composite positive electrode material prepared above to obtain a sulfur content of 80%, and conduct it with the conductive agent (Super P conductive carbon black), binder (polyvinylidene fluoride (PVDF)) according to the mass ratio of 8:1:1 Prepare electrode slurry (80 parts of bentonite / sulfur composite material, 10 parts of conductive agent, 10 parts of binder), and then coat it on the aluminum foil current collector to prepare a sulfur loading capacity of 2 mg S / cm 2 the positive plate.

[0052] The battery assembly and testing conditions are as follows: the above-mentioned positive electrode is used as the positive electrode of the lithium-sulfur secondary battery, the lithium metal sheet is used as the negative electrode, and the electrolyte is 1M LiTFSI / DOL:DME (1:1)+2% LiNO 3 , the amount of electrolyte was 15 μL / mg S, and assembled into a CR2025 button cell in an argon-filled glove box.

[0053] Carry out constant current charge and di...

Embodiment 2

[0055] Compared with Example 1, the difference is that the sulfur content of the bentonite / sulfur composite positive electrode material is 85%, the conductive agent is Ketjen black, and the mixing mass ratio of the bentonite / sulfur composite positive electrode material, conductive agent and binder is different ,Specifically:

[0056] Take the bentonite / sulfur composite cathode material prepared above with a sulfur content of 85%, and prepare an electrode with a conductive agent (Ketjen Black) and a binder (polyvinylidene fluoride (PVDF)) in a mass ratio of 7:2:1 Slurry (70 parts of bentonite / sulfur composite material, 20 parts of conductive agent, 10 parts of binder), and then coated on the aluminum foil current collector, the prepared sulfur loading capacity is 2mg S / cm 2 the positive plate.

[0057] The battery assembly and testing conditions are as follows: the above-mentioned positive electrode is used as the positive electrode of the lithium-sulfur secondary battery, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com