Magnetic halloysite nanotube as well as preparation method and application thereof

A technology of halloysite nanotubes and magnetic nanoparticles, which is applied in the field of nanomaterials and can solve the problems of occupying and restricting the application of secondary functionalization of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

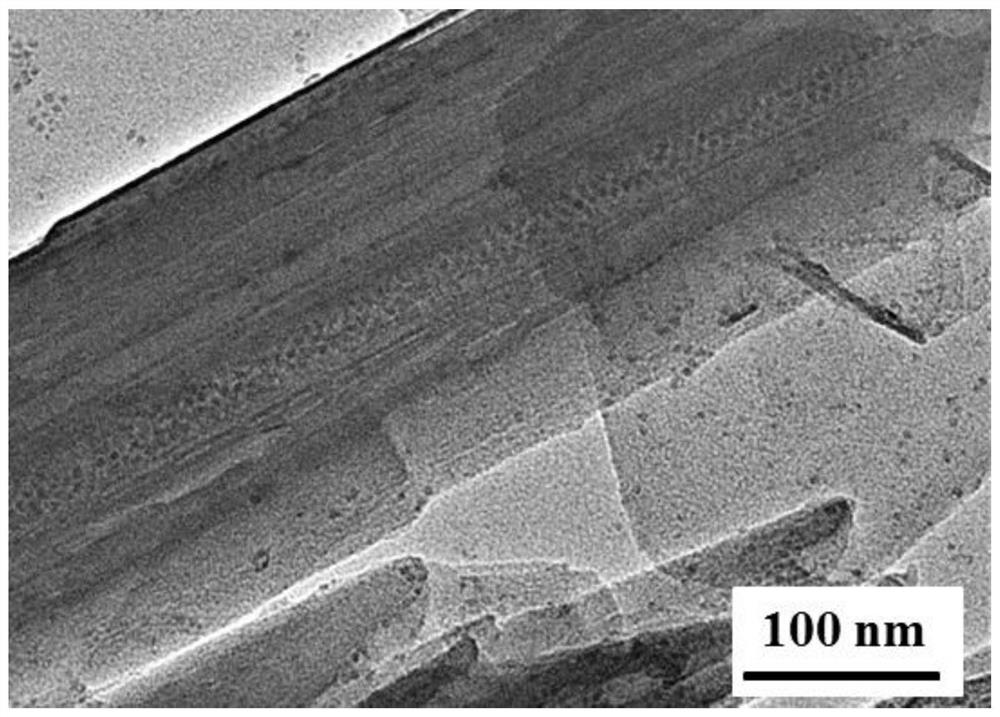

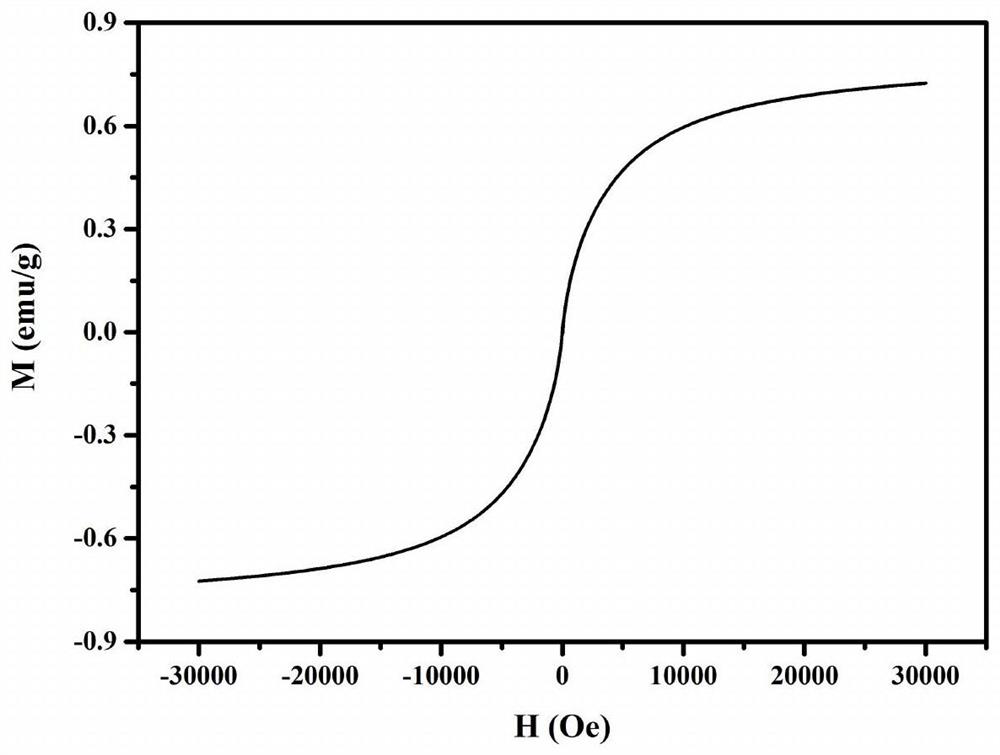

Image

Examples

Embodiment 1

[0037] A method for preparing magnetic halloysite nanotubes. The synthetic method is carried out according to the following steps:

[0038] 1) Prepare organic iron solution: mix 21.46g of diphenyl ether, 2.585g of 1,2-hexadecane glycol, 1.695g of oleic acid, and 1.605g of oleylamine as a solvent for organic iron, and then add 0.7g of iron acetylacetonate;

[0039] 2) Add 0.1 g of halloysite nanotubes to the organic iron solution, and transfer to a three-necked flask and mix evenly;

[0040] 3) Use a vacuum pump to vacuumize the three-necked flask to remove air. In order to better ensure that there is no air in the three-necked flask, each time the system is vacuumed for 30 minutes, then the system is ventilated for 15 minutes to return to normal pressure. Repeat the above vacuuming operation for 3 times. Nitrogen, to ensure that the system is completely under nitrogen atmosphere;

[0041] 4) When the system is completely filled with nitrogen, start to feed cooling water, tu...

Embodiment 2

[0051] A preparation method of magnetic halloysite nanotubes, the synthesis method is carried out according to the following steps:

[0052] 1) Preparation of organic iron solution: mix 25.5g of diphenyl ether, 3.1g of 1,2-hexadecane glycol, 1.85g of oleic acid, and 1.8g of oleylamine as a solvent for organic iron, and then add 1g of iron acetylacetonate;

[0053] 2) 0.2g of halloysite nanotubes are added to the organic iron solution, and transferred to a three-necked flask and mixed evenly;

[0054] 3) Use a vacuum pump to vacuumize the three-necked flask to remove air. In order to better ensure that there is no air in the three-necked flask, each time the system is vacuumed for 30 minutes, then the system is ventilated for 10 minutes to return to normal pressure, and the above is repeated. Vacuumize 4 times, and feed nitrogen directly after the last vacuumize operation to ensure that the system is completely under nitrogen atmosphere;

[0055] 4) When the whole system is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com