Electrolyte of high-elongation electrolytic copper foil and application of electrolyte

A technology of electrolytic copper foil and electrolyte, applied in electrolysis process, electroforming and other directions, can solve the problems of unclear component content control and use, difficult production process control, many additive components, etc., to achieve good quality stability, Adjustment of roughness and mechanical properties, effect of less additive composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

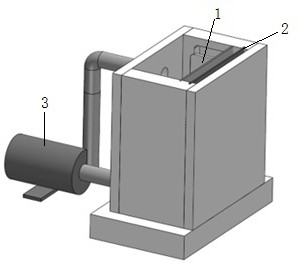

[0042] (1) Electrolyte is configured by copper sulfate pentahydrate, sulfuric acid, hydrochloric acid, sulfur-containing organic matter solution and deionized water, wherein the concentration of copper ions is 70g / L, the concentration of sulfuric acid is 80g / L, and the concentration of chloride ions is 16 mg / L. The concentration of sodium polydithiodipropane sulfonate is 1.0mg / L, and the prepared electrolyte is poured into the flat plate electroplating device.

[0043] (2) A titanium plate coated with an iridium dioxide coating and a pure titanium plate are used as the anode plate and the cathode plate respectively, and the two plates are placed in the electrolyte in parallel. Among them, the deposition surface of the cathode plate is polished with 2000 mesh water sandpaper and polished to a surface roughness of Ra=0.15 μm with a 2.5 μm polishing agent. Use running water to wash from the upper part of the cathode plate to the lower part, and use absorbent cotton to wipe down sl...

Embodiment 2

[0048] The concentration of sodium polydithiodipropane sulfonate is 3mg / L, the concentration of chloride ion is 20mg / L, the deposition temperature is 60°C, and the current density is 65 A / dm 2 , and the rest are the same as in Embodiment 1.

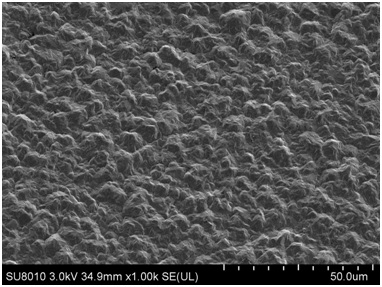

[0049] The matte roughness Rz of the prepared copper foil is 1.882 μm, the (220) texture coefficient accounts for 69.81%, the color of the copper foil is normal, and the warpage is less than 10mm; after being stored at room temperature for one month, the room temperature tensile strength of the copper foil is 312MPa, The elongation at room temperature is 10.67%.

Embodiment 3

[0051] The copper ion concentration is 100g / L, the sulfuric acid concentration is 130g / L, the sodium polydisulfide dipropane sulfonate concentration is 5mg / L, and the chloride ion concentration is 40mg / L, and all the other are identical with embodiment one.

[0052] The matte roughness Rz of the prepared copper foil is 1.612 μm, the (220) texture coefficient accounts for 71.81%, the color of the copper foil is normal, and the warpage is less than 10mm; after being stored at room temperature for one month, the normal temperature tensile strength of the copper foil is 332MPa, The elongation at room temperature is 10.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com