Lithium ion capacitor diaphragm and production method thereof

A production method, lithium ion technology, applied in the direction of hybrid capacitor separators, capacitors, electrolytic capacitors, etc., can solve the problems of nanoparticle agglomeration, fiber film influence, etc., achieve simple process, reduce liquid absorption rate, and improve ion conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

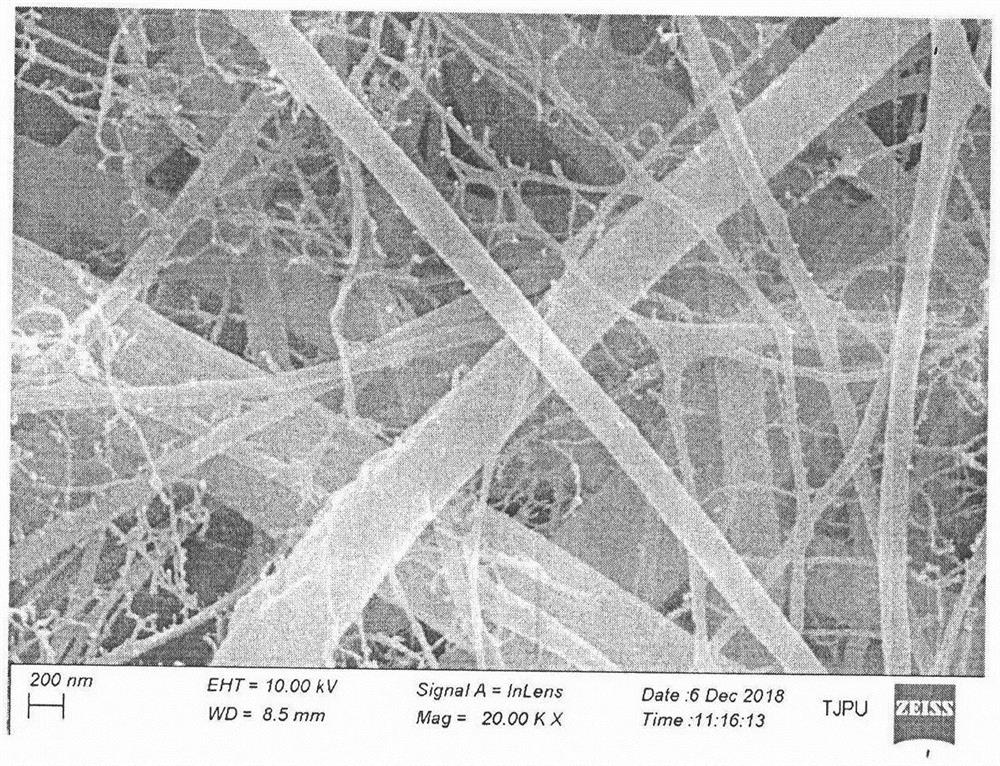

Image

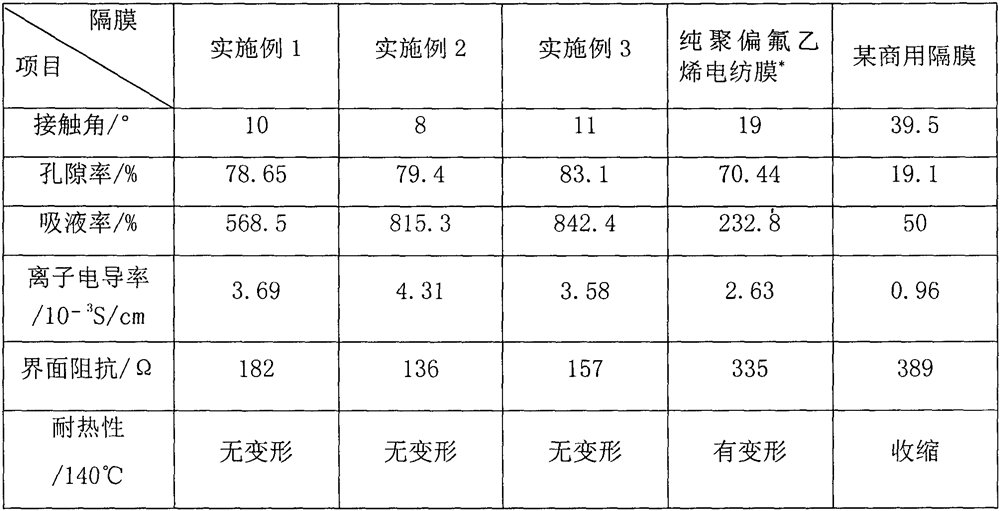

Examples

Embodiment 1

[0023] (1) Polyvinylidene fluoride and 0.025mol / L TBAPF6 with a concentration of 16% are dissolved in N, N-dimethylformamide and acetone mixed solvent (the volume ratio of the two is 3: 1), and then using magnetic force The stirrer was stirred at room temperature for 1 hour to form a uniformly mixed spinning precursor solution.

[0024] (2) Slowly add the spinning solution configured in the above step (1) into the syringe, the inner diameter of the needle used is 0.35mm, and the extrusion rate of the needle solution is 0.5mL h -1 . A rotating cylinder covered with aluminum foil serves as a receiving device, and the receiving distance between the syringe tip and the collector is 15 cm. During the electrospinning process, the applied electrostatic voltage was 30kV. After the solvent evaporated, the polyvinylidene fluoride multiscale nanofiber membrane doped with TBAPF6 organic branched salt was obtained on the receiving device.

[0025] (3) Put the polyvinylidene fluoride mul...

Embodiment 2

[0027] (1) Dissolve polyvinylidene fluoride and 0.05mol / L TBAPF6 with a concentration of 14% in N,N-dimethylformamide and acetone mixed solvent (the volume ratio of the two is 4:1), and then use magnetic force to The stirrer was stirred at room temperature for 1.5 hours to form a uniformly mixed spinning precursor solution.

[0028] (2) Slowly add the spinning solution configured in the above step (1) into the syringe, the inner diameter of the needle used is 0.45mm, and the extrusion rate of the needle solution is 1.0mL h -1 . A rotating cylinder covered with aluminum foil serves as a receiving device, and the receiving distance between the syringe tip and the collector is 20 cm. During the electrospinning process, the applied electrostatic voltage was 25kV. After the solvent evaporated, the polyvinylidene fluoride multiscale nanofiber membrane doped with TBAPF6 organic branched salt was obtained on the receiving device.

[0029] (3) Put the polyvinylidene fluoride multisc...

Embodiment 3

[0031] (1) Polyvinylidene fluoride and 0.075mol / L TBAPF6 with a concentration of 15% are dissolved in N, N-dimethylformamide and acetone mixed solvent (the volume ratio of the two is 2: 1), and then use magnetic force The stirrer was stirred at room temperature for 2 hours to form a uniformly mixed spinning precursor solution.

[0032] (2) Slowly add the spinning solution configured in the above step (1) into the syringe, the inner diameter of the needle used is 0.45mm, and the extrusion rate of the needle solution is 1.5mL h -1 . A rotating cylinder covered with aluminum foil serves as a receiving device, and the receiving distance between the syringe tip and the collector is 10 cm. During the electrospinning process, the applied electrostatic voltage was 20kV. After the solvent was evaporated, the polyvinylidene fluoride multiscale nanofibrous membrane doped with TBAPF6 organic branched salt was obtained on the receiving device.

[0033](3) Put the polyvinylidene fluoride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com