Lithium metal composite electrode with controllable nucleation and growth of lithium metal and preparation method thereof

A composite electrode and metal lithium technology, applied in the direction of negative electrode, battery electrode, lithium storage battery, etc., can solve the problems of limiting practical application, and achieve the effects of avoiding microstructure design and preparation, good practicability, and prolonging cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

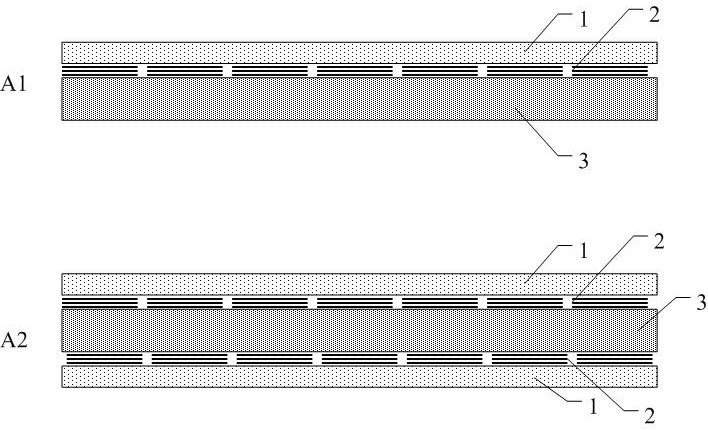

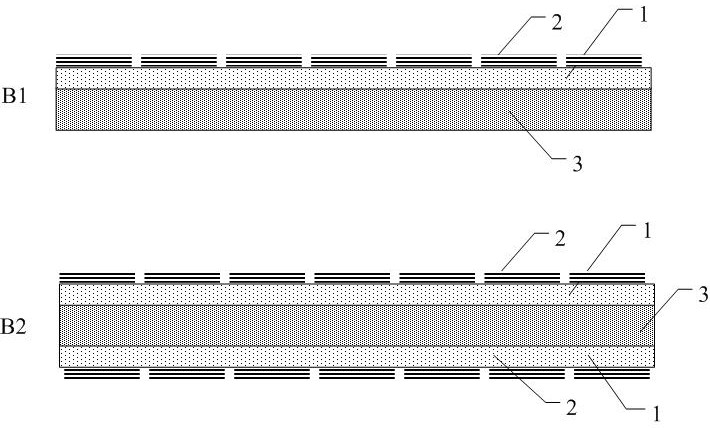

Embodiment 1

[0060] This embodiment provides a lithium metal composite electrode with controllable nucleation and growth of lithium metal and its preparation method. The conductive nanosheets 21 are transition metal carbides (MXenes), the current collector layer 3 is metal copper foil, and the metal lithium layer 1 is metal lithium foil as an example to illustrate the preparation method of the lithium metal composite electrode. Among them, Ti is selected in MXenes 3 C 2 T X For example, its preparation method includes step 1) to step 3):

[0061] Step 1): In an argon atmosphere, the metal lithium foil is prepared on the surface of the metal copper foil by rolling to obtain the current collector metal lithium layer 31;

[0062] Step 2): Put Ti 3 C 2 T X Transfer and disperse on the metal copper foil of the dielectric layer 4 by the Langmuir-Blodgett method, and then dry under vacuum at 60°C for 24 hours to remove residual moisture to obtain the composite dielectric layer 24;

[0063]...

Embodiment 2

[0074] This embodiment provides a method for preparing Ti in transition metal carbides (MXenes) 3 C 2 T X nanosheet method to prepare Ti 3 C 2 T X Nanosheets can be used to prepare "metal lithium-Ti" in Example 1 3 C 2 T X -Lithium metal composite electrode with the structure of "copper foil". The steps include steps 1) and 2):

[0075] Step 1): Put 1g Ti 3 AlC 2 Immerse the powder in 20ml of 5mol / L HCl solution and stir for 40h in a water bath at 35°C to completely etch Ti with HCl 3 AlC 2 Al layer in

[0076] Step 2): The suspension obtained in step 1) is suction-filtered, washed repeatedly with deionized water, and then freeze-dried at -40°C to obtain a black powder that is Ti 3 C 2 T X Nanosheets.

[0077] Ti obtained by this method 3 C 2 T X The single-layer thickness of the nanosheet is 0.5nm, and the sheet diameter is between 1 and 10 microns.

[0078] In this embodiment, the raw material Ti in step 1) can be 3 AlC 2 Replaced with other types of MXene...

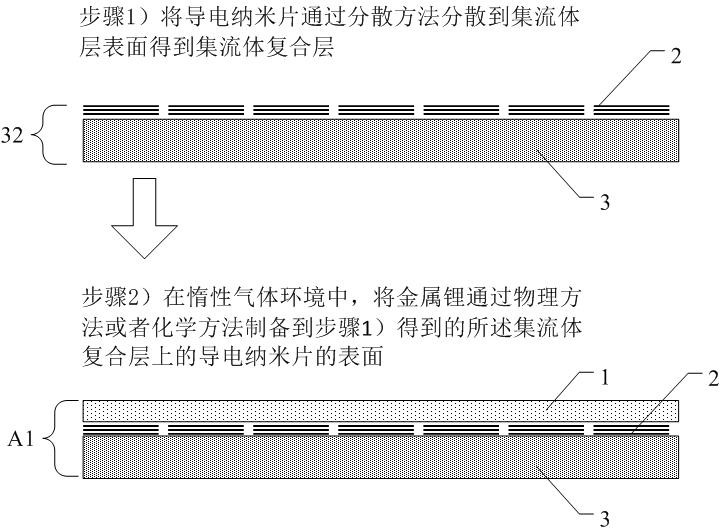

Embodiment 3

[0080] This embodiment provides a lithium metal composite electrode with controllable nucleation and growth of metal lithium and its preparation method. The conductive nanosheets 21 in the lithium metal composite electrode are transition metal carbides (MXenes), and the current collector layer 3 is metal Copper foil, metal lithium layer 1 is metal lithium foil as an example to illustrate the method of this embodiment. where Nb in MXenes 2 C as an example, including step 1) to step 2):

[0081] Step 1): Add Nb 2 C is transferred and dispersed on the metal copper foil by the Langmuir-Blodgett method, and then dried under vacuum at 60°C for 24 hours to remove residual moisture, and the current collector composite layer 32 is obtained;

[0082] Step 2): In an argon atmosphere, prepare metal lithium foil by rolling to Nb on the current collector composite layer 32 obtained in step 1). 2 C's surface.

[0083] Prepared by the above method to obtain "metal lithium-Nb 2 Lithium me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com