High-strength impermeable concrete and preparation method thereof

A technology of impermeable concrete and concrete, which is applied in the field of building materials, can solve problems such as leakage and restrict the application of concrete materials, and achieve the effects of simplifying process steps, improving mechanical properties, and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

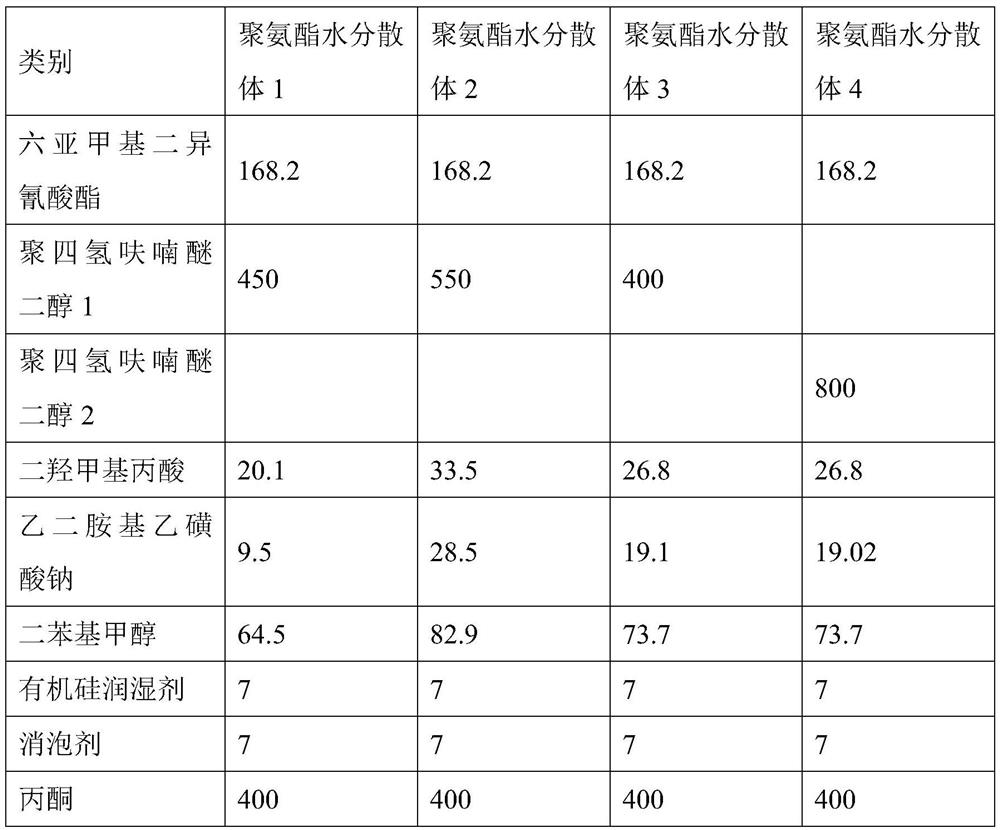

[0044] The preparation method of polyurethane aqueous dispersion 1 is:

[0045] Step 1: Add polytetrahydrofuran ether glycol and dimethylol propionic acid into the reactor, start stirring, control the temperature of the reactor at 70°C, slowly add isocyanate, react for 4 hours, add sodium ethylenediamine ethanesulfonate, and react 3 hours;

[0046] Step 2, continue to add acetone into the reactor, stir evenly and then slowly add benzylmethanol, control the temperature of the reactor to 50°C, and react for 5 hours;

[0047] Step 3, continue to add a triethylamine aqueous solution with a mass concentration of 2% in the reactor, control the pH value of the mixture in the range of 6 to 8, stir evenly, remove acetone by distillation under reduced pressure, add organic silicon wetting agent, For defoaming agent, add deionized water to the reactor until the solid content of the mixture is 40%, and stir to obtain the polyurethane aqueous dispersion 1.

[0048] The preparation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com