Preparation method of Co9S8/Ni-Co-Mo oxyhydroxide hollow core-shell electrode material

An oxyhydroxide and ni-co-mo technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems that limit wide application and the electrodes are not flexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

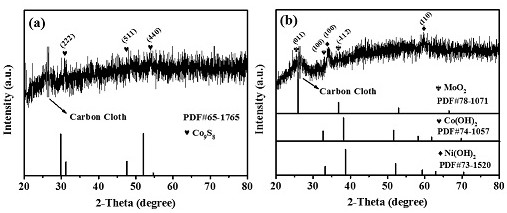

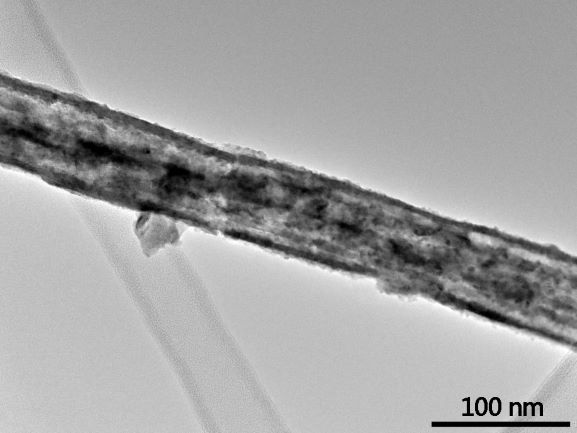

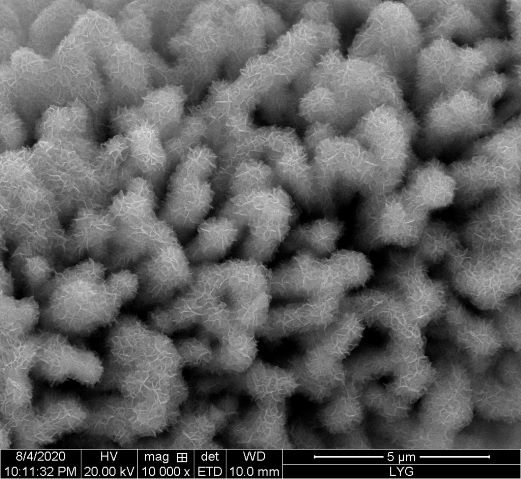

[0015] Embodiment 1: (1) with 0.06 M Co (NO 3 ) 2 ·6H 2 O, 0.3M CH 4 N 2 O, 0.13 M NH 4 Dissolve F in 64 mL of deionized water, transfer it to an 80 mL autoclave after fully dissolving and mixing, put the carbon cloth (CC) into the autoclave, and react at 120 °C for 5 hours to obtain basic cobalt carbonate grown on the carbon cloth nanowires, and then transfer the carbon cloth on which the basic cobalt carbonate nanowires grew to a layer filled with 0.01 M Na 2 S aqueous solution in an 80 mL autoclave was reacted at 120 °C for 8 h to obtain hollow Co with a length of about 10–11 μm 9 S 8 nanotubes; (2) 12.5 mM Ni(NO 3 ) 2 ·6H 2 O, 37.5 mM Co(NO 3 ) 2 ·6H 2 O, 22.5 mM Na 2 MoO 4 2H 2 O, 12.5 mM C 6 h 12 N 4 and 25 mM CH 4 N 2 O was dissolved in 30 mL of distilled water in turn, transferred to a 40 mL autoclave after fully dissolved, reacted hydrothermally at 120 °C for 3 h, cleaned ultrasonically, and dried in vacuum. 9 S 8 Epitaxial growth of Co on the su...

Embodiment 2

[0016] Embodiment 2: 0.06 M Co (NO 3 ) 2 ·6H 2 O, 0.3M CH 4 N 2 O, 0.13 M NH 4 F was dissolved in 64 mL of deionized water, and transferred to an 80 mL autoclave after being fully dissolved and mixed. Put the carbon cloth (CC) into the autoclave and react at 120 °C for 5 h to obtain basic carbonic acid grown on the carbon cloth. Cobalt nanowires, and then transfer the carbon cloth with basic cobalt carbonate nanowires to a layer filled with 0.01 M Na 2 S aqueous solution in an 80 mL autoclave was reacted at 120 °C for 8 h to obtain hollow Co with a length of about 10–11 μm 9 S 8 nanotubes; (2) 25 mM Ni(NO 3 ) 2 ·6H 2 O, 75 mM Co(NO 3 ) 2 ·6H 2 O, 45 mM Na 2 MoO4 2H 2 O, 25 mM C 6 h 12 N 4 and 50 mM CH 4 N 2 O was dissolved in 30 mL of distilled water in turn, transferred to a 40 mL autoclave after fully dissolved, reacted hydrothermally at 120 °C for 3 h, cleaned ultrasonically, and dried in vacuum. 9 S 8 Epitaxial growth of Co on the surface of nanotubes ...

Embodiment 3

[0017] Embodiment 3: (1) with 0.06 M Co (NO 3 ) 2 ·6H 2 O, 0.3M CH 4 N 2 O, 0.13 M NH 4 Dissolve F in 64 mL of deionized water, transfer it to an 80 mL autoclave after fully dissolving and mixing, put the carbon cloth (CC) into the autoclave, and react at 120 °C for 5 hours to obtain basic cobalt carbonate grown on the carbon cloth nanowires, and then transfer the carbon cloth on which the basic cobalt carbonate nanowires grew to a layer filled with 0.01 M Na 2 S aqueous solution in an 80 mL autoclave was reacted at 120 °C for 8 h to obtain hollow Co with a length of about 10–11 μm 9 S 8 nanotubes; (2) 50 mM Ni(NO 3 ) 2 ·6H 2 O, 150 mM Co(NO 3 ) 2 ·6H 2 O, 90 mM Na 2 MoO 4 2H 2 O, 50 mM C 6 h 12 N 4 and 100 mM CH 4 N 2 O was dissolved in 30 mL of distilled water in turn, transferred to a 40 mL autoclave after fully dissolved, reacted hydrothermally at 120 °C for 3 h, cleaned ultrasonically, and dried in vacuum. 9 S 8 Epitaxial growth of Co on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com