Multi-mixed composite salt monomer and multi-element polybenzodiazole liquid crystal polymer with antioxidant stability and preparation and application of the multi-mixed composite salt monomer and multielement polybenzodiazole liquid crystal polymer

A technology of liquid crystal polymers and polybenzodiazoles, which is applied in the preparation of amino compounds, organic compounds, and aminohydroxyl compounds, etc., which can solve the problems of compounding, lack of light resistance and compression performance and improvement, high price, and decline in mechanical properties And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

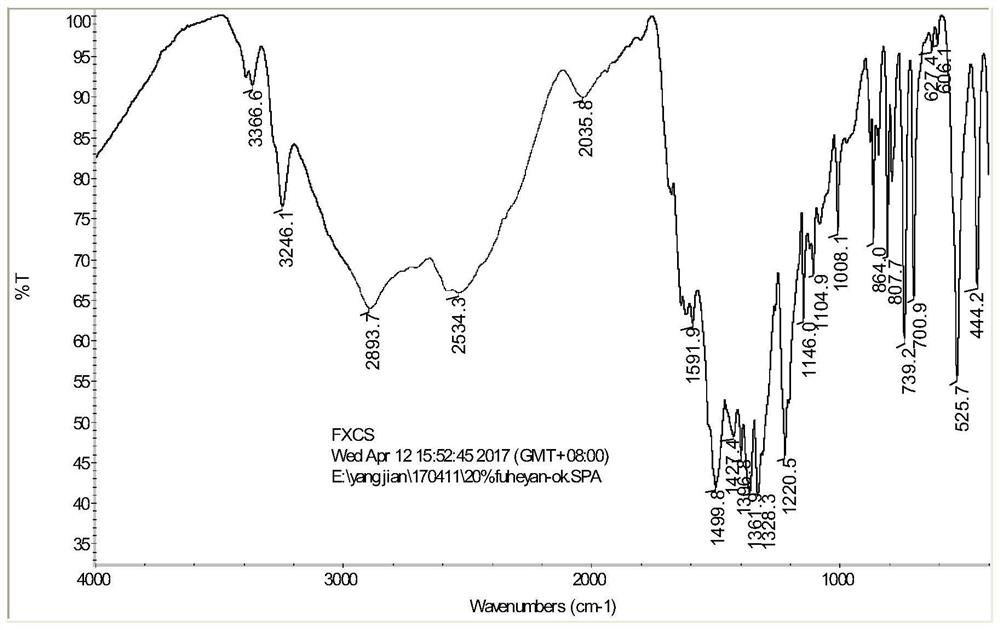

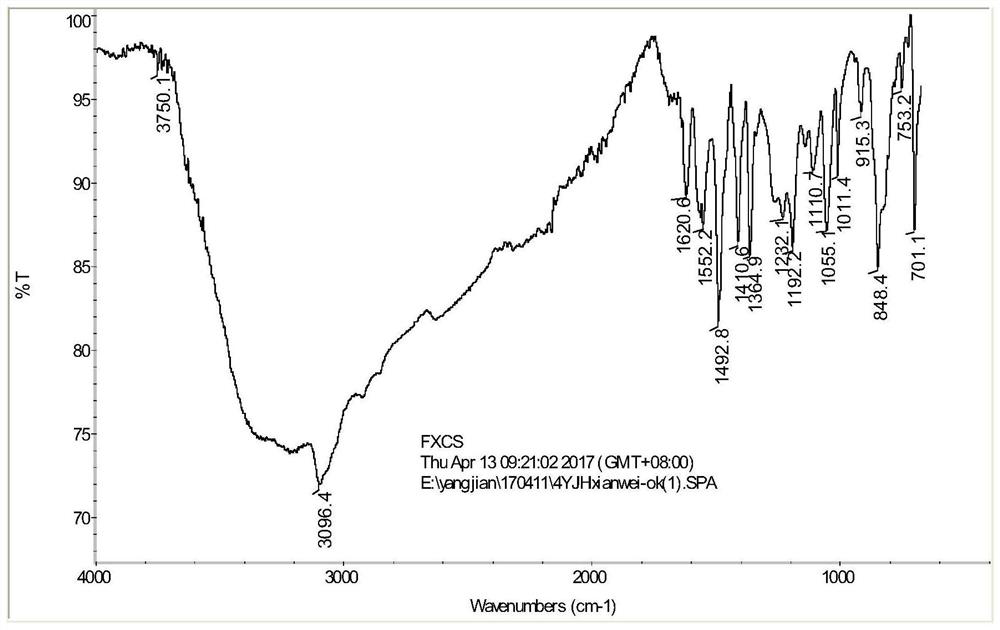

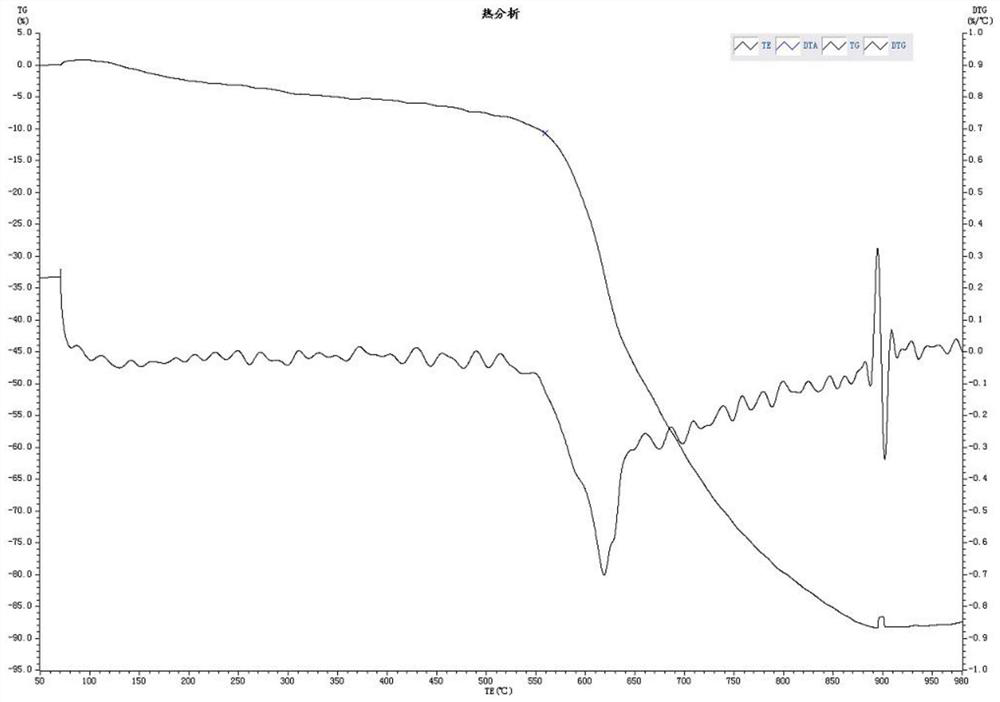

[0159] Preparation and application of embodiment 1 four mixed compound salt monomer n(DAR / TPA)-and-m(TAB / DHTA)

[0160] (1) Preparation of four-mix compound salt monomer

[0161]

[0162] Add 200g of deoxygenated water, 5.12g of 96% NaOH (0.1229mol) and 6.65g (0.04mol) of terephthalic acid (TPA) and 1.98g (0.01mol) of 2,5-dihydroxyterephthalic acid in the glass reactor (DHTA), stirring and raising the temperature to 50°C until it dissolves into a light brown transparent solution, under the protection of nitrogen, slowly add 8.78g (0.0412mol) of 4,6-diaminoresorcinol hydrochloride (DARH, containing sn 2+ 2646ppm) and 2.93g (0.0103mol) 1,2,4,5-tetraaminobenzene hydrochloride (TABH, Sn 2+ 1060ppm) dissolved in 180g of deoxygenated water, stirred and heated up to 70°C for hot filtration, the wet filter cake was beaten and washed with 180mL of deoxygenated water, filtered at room temperature, and vacuum-dried at 70°C to obtain four monomers of TPA, DAR, DHTA, and TAB (mol rat...

Embodiment 2 4

[0167] Preparation and application of embodiment 2 four-mix compound salt monomer n(DAR / TPA)-and-m(TABP / DHTA)

[0168] (1) Preparation of four-mix compound salt monomer

[0169]

[0170]Add 200g of deoxygenated water, 5.12g of 96% NaOH (0.1229mol) and 6.65g (0.04mol) of terephthalic acid (TPA) and 1.98g (0.01mol) of 2,5-dihydroxyterephthalic acid in the glass reactor (DHTA), stirring and raising the temperature to 50°C until it dissolves into a light brown transparent solution, under the protection of nitrogen, slowly add 8.78g (0.0412mol) of 4,6-diaminoresorcinol hydrochloride (DARH, containing sn 2+ 2646ppm) and 3.71g (0.103mol) of 3,3',4,4'-tetraaminobiphenyl hydrochloride (TABPH) dissolved in 180g of deoxygenated water solution, after adding, stir and heat up to 70°C for hot filtration, wet filtration The cake was beaten and washed with 180 mL of deoxygenated water, filtered at room temperature, and vacuum-dried at 70°C to obtain a 20% dihydroxyl group formed by TPA, ...

Embodiment 3 3

[0175] Example 3 Preparation and Application of Trimix Compound Salt Monomer (DAR)-and-(nTPA / mDHTA)

[0176] (1) Preparation of three mixed compound salt monomers

[0177]

[0178] Add 200g of deoxygenated water, 4.27g of 96% NaOH (0.1025mol) and 8.22g (0.0495mol) of terephthalic acid (TPA) and 0.10g (0.0005mol) of 2,5-dihydroxyterephthalic acid in the glass reactor (DHTA), stirring and raising the temperature to 50°C until it dissolves into a light brown transparent solution, under the protection of nitrogen, slowly add 10.97g (0.0515mol) of 4,6-diaminoresorcinol hydrochloride (DARH, containing sn 2+ 2646ppm) dissolved in 180g deoxygenated water solution, after the addition, stir and heat up to 70°C for hot filtration, the wet filter cake is beaten and washed with 180mL deoxygenated water, filtered at room temperature, and vacuum-dried at 70°C to obtain TPA, DHTA, DAR triple monomer (mol Ratio 0.99:0.01:1.0, n / m=99) formed 1% dihydroxy modified PBO trimix compound salt m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com